A gas flameless combustion device and combustion method with extremely low nitrogen oxide emissions

A nitrogen oxide, flameless combustion technology, applied in combustion methods, gas fuel burners, burners, etc., can solve the problems of poor combustion stability, long preheating time, insufficient consideration, etc., to improve combustion stability and The effect of safety, simple structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

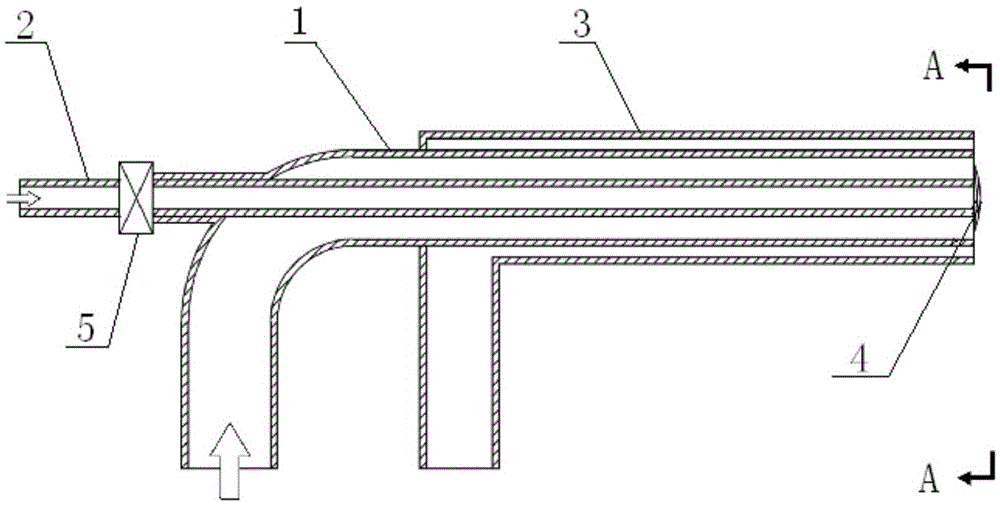

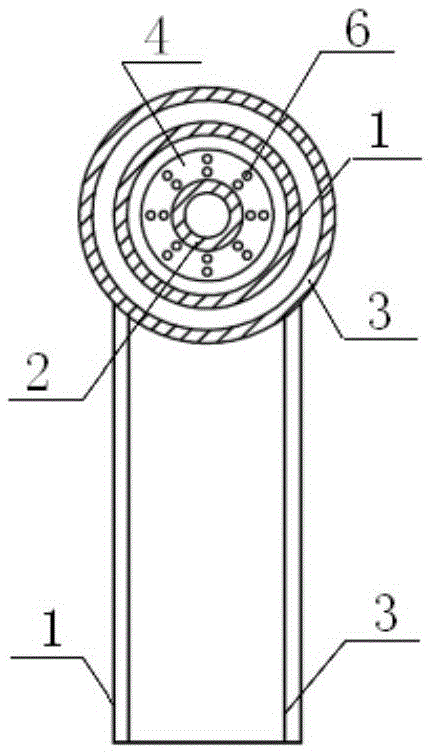

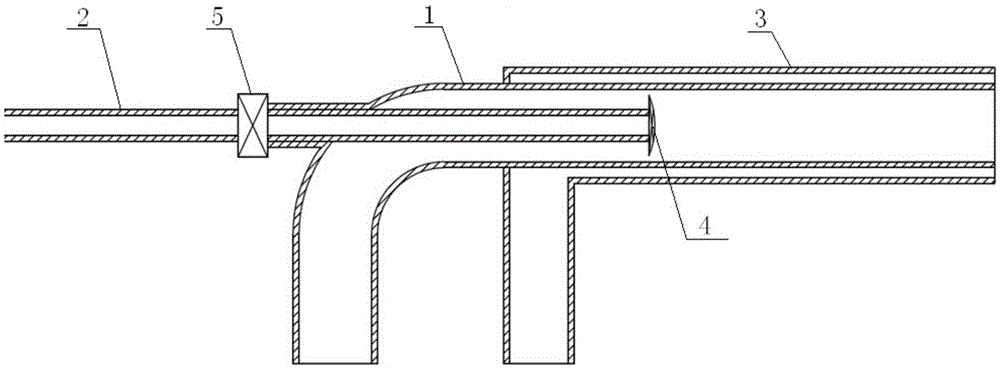

[0020] like figure 1 , figure 2 As shown, the present invention includes an air nozzle 1, a central gas nozzle 2, an outer gas nozzle 3 and a flame stabilizer 4.

[0021] The air nozzle 1 is an L-shaped pipe, one section of the L-shaped pipe is arranged horizontally, the end of the horizontal section of the L-shaped pipe is the outlet of the nozzle, and the other end of the L-shaped pipe is an air inlet; There is a horizontal branch 11.

[0022] The central gas nozzle 2 is a straight pipe, which passes through the horizontal branch pipe 11 and stretches into the horizontal section of the air nozzle 1 in parallel. An annular gap is left between the air nozzle 1 and the central gas nozzle 2 to form an air passage. The central gas nozzle 2 is connected with the horizontal branch pipe 11 through a sealing joint 5, and the sealing joint 5 has the funct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com