Mini-type pressure reduction pipe

A decompression tube and miniature technology, which is applied to functional valve types, safety valves, engine components, etc., can solve the problems of unstable flame state, flow fluctuation, and inability to install, so as to avoid unstable flame state and stable gas output flow. , the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

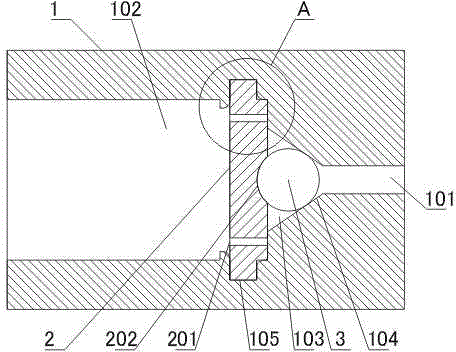

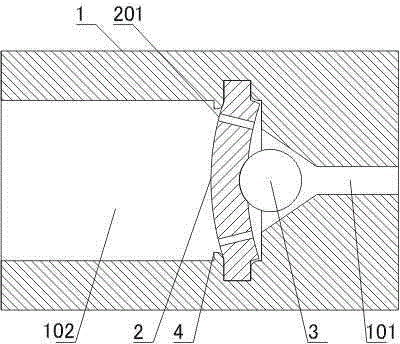

[0039] like figure 1 As shown, the miniature decompression tube includes a pipe body 1, and connecting threads are provided at both ends of the pipe body 1. The space in the pipe body 1 is composed of a high-pressure chamber 101 and a low-pressure chamber 102; the inner diameter of the high-pressure chamber 101 is smaller than the inner diameter of the low-pressure chamber 102 The rubber sheet 2, the rubber sheet 2 is arranged in the low-pressure chamber 102 and is connected with the inner surface of the low-pressure chamber 102, the rubber sheet 2 is in contact with the end of the high-pressure chamber 101, and the rubber sheet 2 and the end of the high-pressure chamber 101 are evenly opened There are a plurality of air outlet holes 201, and an arc groove 202 is opened at the center of the rubber sheet 2; the accommodation cavity 103 is set at one end of the high-pressure chamber 101 close to the rubber sheet 2, and the sealing ball 3 is placed in the arc groove In 202 , the ...

Embodiment 2

[0046] like figure 1 As shown, this embodiment is based on Embodiment 1, and the transition is a tapered surface 104 .

[0047]The sealing ball 3 cooperates with the tapered surface 104 to improve the sealing performance and further prevent the gas in the high-pressure chamber 101 from entering the low-pressure chamber 102 when the user does not use the gas, causing the gas pressure to be too high when the user starts to use the gas.

Embodiment 3

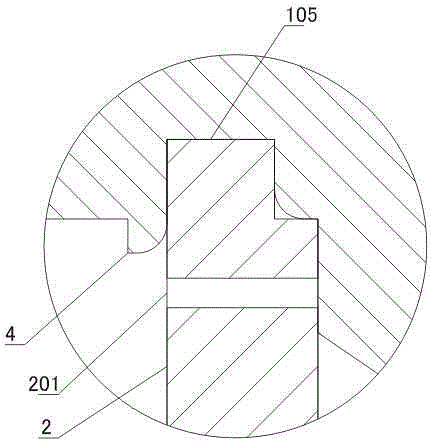

[0049] like figure 1 and image 3 As shown, this embodiment is based on Embodiment 1 or 2, the inner surface of the low-pressure chamber 102 is provided with an annular groove 105 , and the edge of the rubber sheet 2 is located in the annular groove 105 .

[0050] The circular groove 105 is provided, and the rubber sheet 2 can be conveniently installed in the circular groove 105, which improves the assembly efficiency of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com