Pile-forming construction equipment for composite foundation piles

A technology of composite foundation and construction equipment, applied in the direction of foundation structure engineering, sheet pile wall, construction, etc., can solve the problems of limited construction technology, reduced bearing capacity of single pile, high site requirements, and achieve good controllability and operability The effect of increasing the density of replacement and high site requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

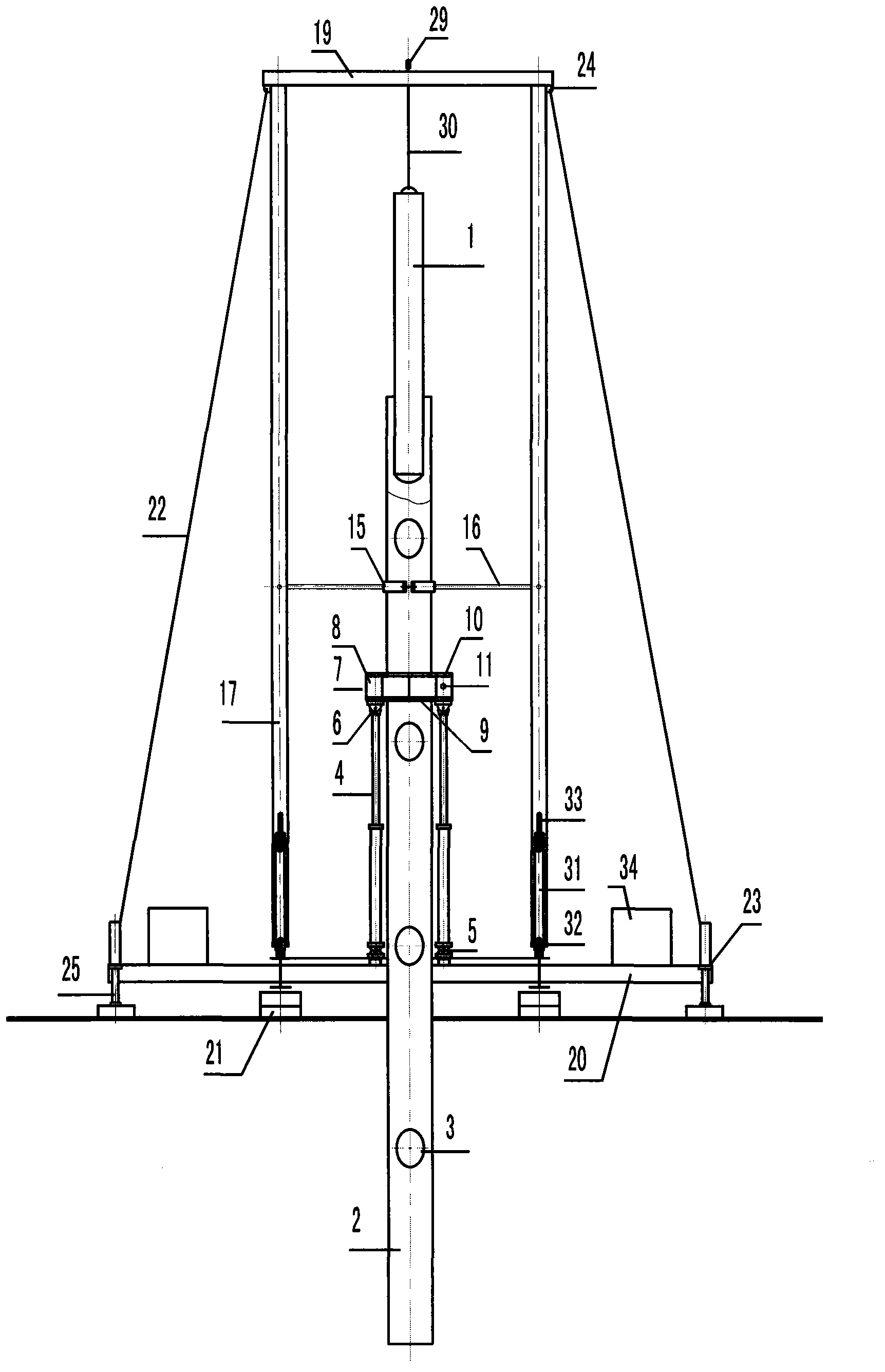

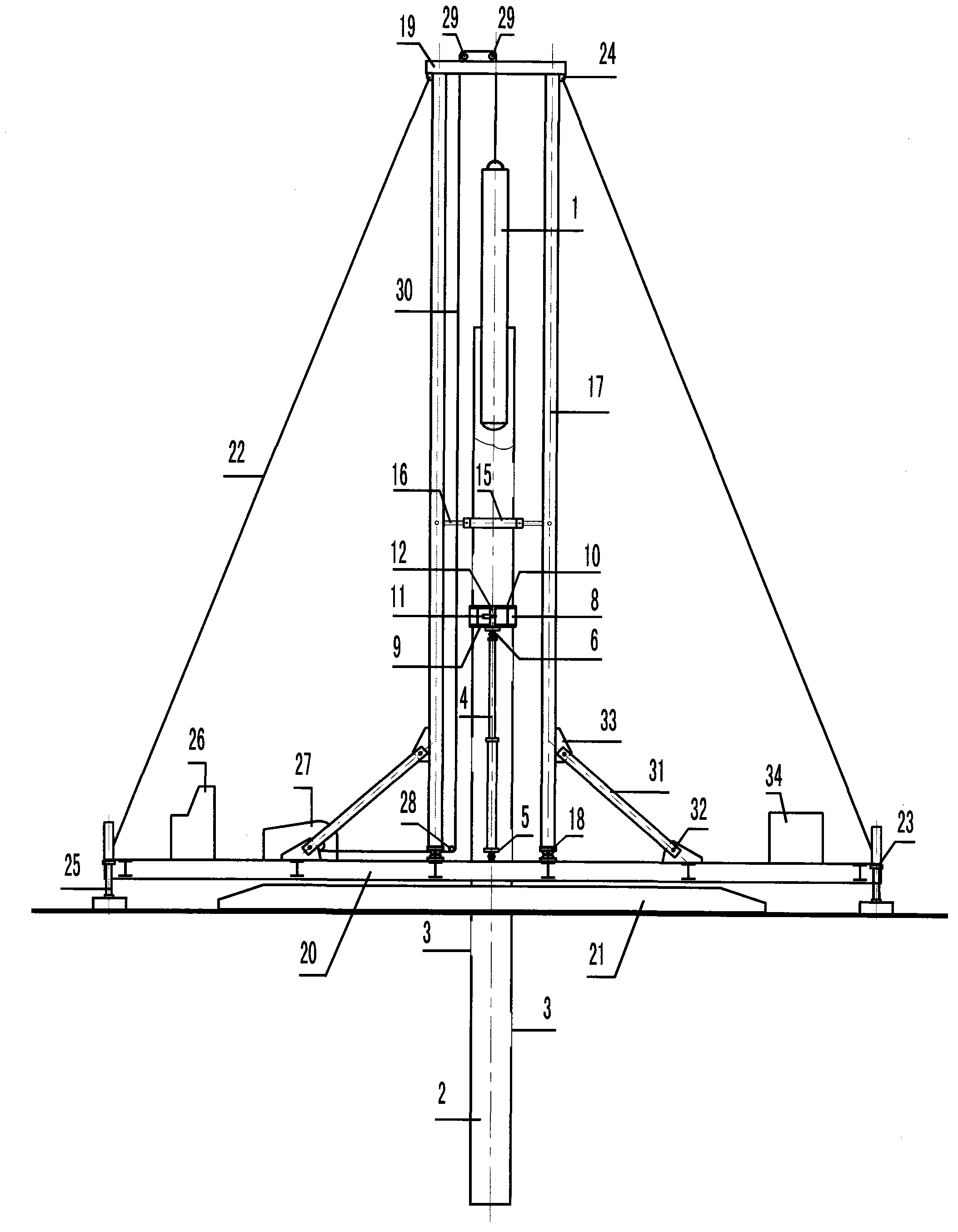

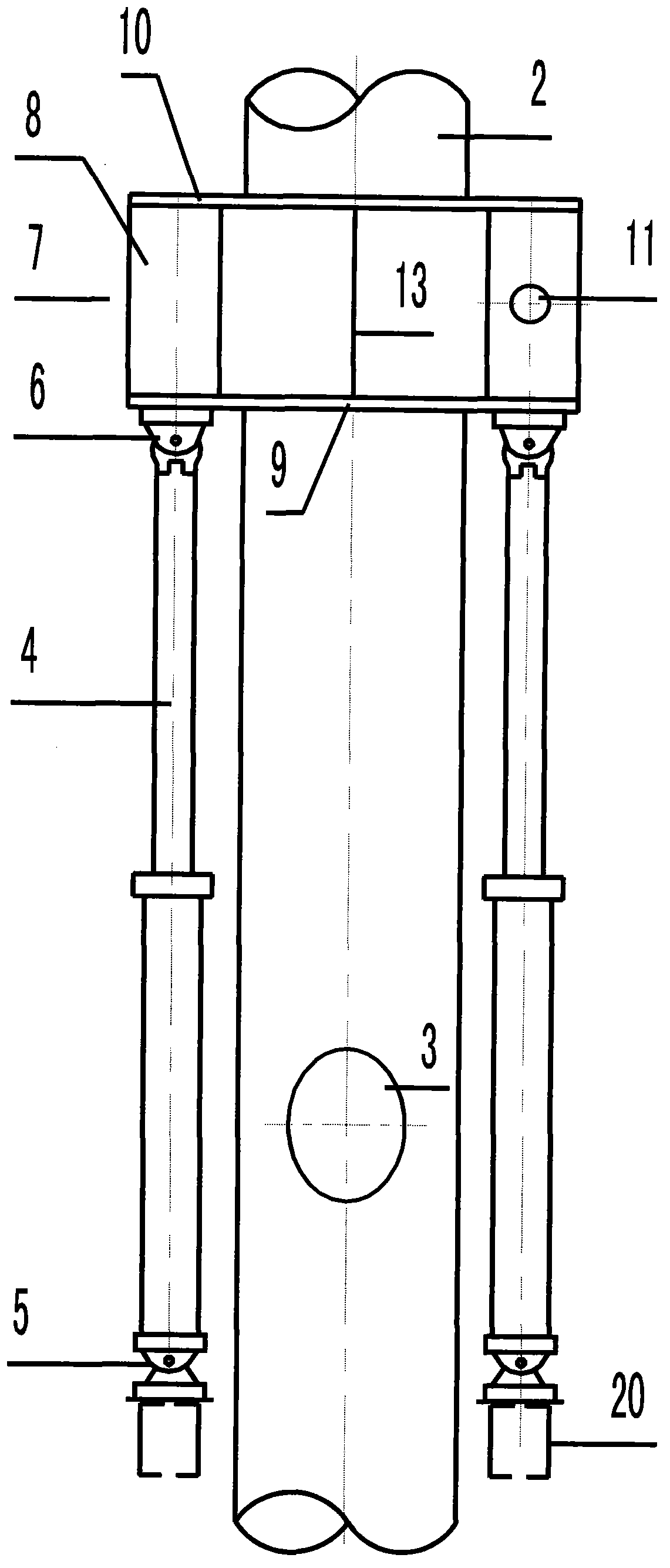

[0020] figure 1 with figure 2 A schematic diagram showing the component composition of an embodiment of the construction equipment of the present invention, a hydraulic support foot 25 is installed at each of the four corners of the chassis 20, and the hydraulic support foot 25 is extended to support the chassis 20 and the pile frame 17 during construction, during transportation and storage put away. The bottom of the chassis 20 is provided with a walking support plate 21, and the chassis 20 and the walking support plate 21 are connected at one point by ball twisting at the middle point. 21 After the hydraulic support feet 25 are put away, they can walk on the natural ground and complete actions such as going up and down slopes and rotating. During the working state, the walking support plate 21 plays an auxiliary supporting role, and the walking support plate 21 of the present invention is a hydraulic walking type walking support plate.

[0021] The pile frame 17 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com