High stripping force PET (polyethylene terephthalate) protective film pressure sensitive adhesive and preparation method thereof

A protective film, high peeling technology, applied in the direction of adhesives, film/sheet adhesives, non-polymer adhesive additives, etc. problem, to achieve the effect of high peeling force, convenient condition control, and conducive to process promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

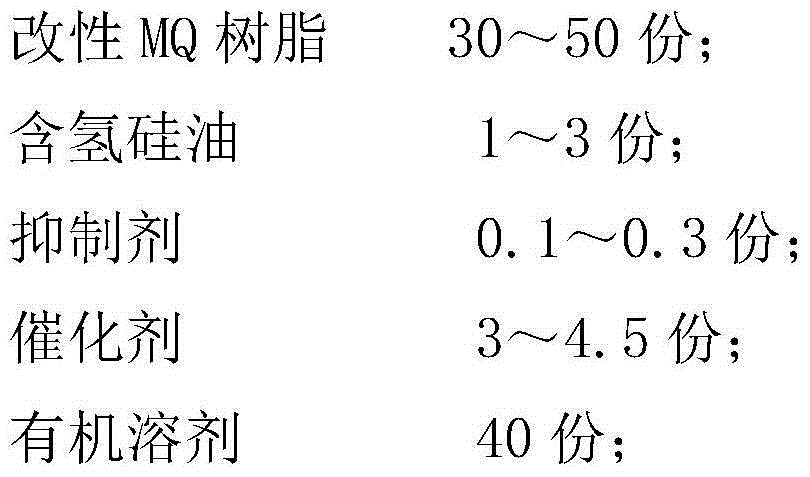

[0030] A kind of PET protective film pressure-sensitive adhesive with high peeling force, its raw material formula is made up of each component of following parts by weight:

[0031]

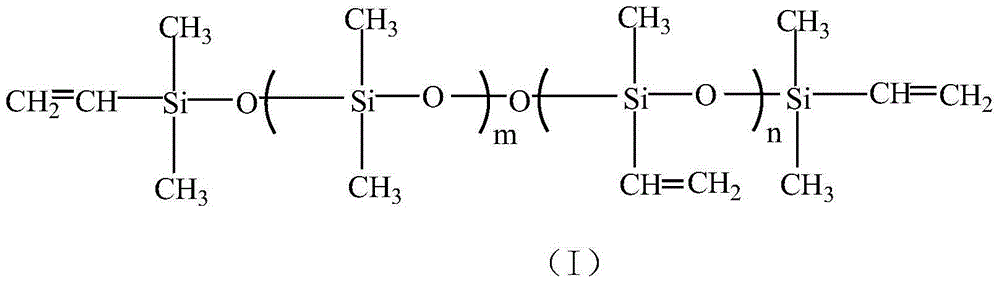

[0032] Wherein, the base rubber is vinyl raw rubber, and the structural formula is as shown in general formula (I):

[0033]

[0034] In the above-mentioned general formula (I), m=8000, n=90;

[0035] The modified MQ resin is vinyl MQ resin;

[0036] The structural formula of the hydrogen-containing silicone oil is shown in general formula (II):

[0037]

[0038] In the above general formula (II), p=45;

[0039] The inhibitor is 3,5-dimethyl-1-hexyn-3-ol;

[0040] The catalyst Castel platinum catalyst, the platinum content is 3000pmm;

[0041] Described organic solvent is xylene.

[0042] The above-mentioned preparation method of the PET protective film pressure-sensitive adhesive with high peeling force comprises the steps:

[0043] (1) First mix the base glue, modified MQ resin ...

Embodiment 2

[0048] A kind of PET protective film pressure-sensitive adhesive with high peeling force, its raw material formula is made up of each component of following parts by weight:

[0049]

[0050] Wherein, the base rubber is vinyl raw rubber, and the structural formula is as shown in general formula (I):

[0051]

[0052] In the above-mentioned general formula (I), m=8000, n=90;

[0053] The modified MQ resin is vinyl MQ resin;

[0054] The structural formula of the hydrogen-containing silicone oil is shown in general formula (II):

[0055]

[0056] In the above general formula (II), p=45;

[0057] The inhibitor is 2-propyn-1-alcohol;

[0058] The catalyst Castel platinum catalyst, the platinum content is 3000pmm;

[0059] Described organic solvent is xylene.

[0060] The above-mentioned preparation method of the PET protective film pressure-sensitive adhesive with high peeling force comprises the steps:

[0061] (1) First mix the base glue, modified MQ resin and org...

Embodiment 3

[0066] A kind of PET protective film pressure-sensitive adhesive with high peeling force, its raw material formula is made up of each component of following parts by weight:

[0067]

[0068]

[0069] Wherein, the base rubber is vinyl raw rubber, and the structural formula is as shown in general formula (I):

[0070]

[0071] In the above general formula (I), m=8000, n=90.

[0072] The modified MQ resin is vinyl MQ resin;

[0073] The structural formula of the hydrogen-containing silicone oil is shown in general formula (II):

[0074]

[0075] In the above general formula (II), p=45;

[0076] The inhibitor is 3,5-dimethyl-1-hexyn-3-ol;

[0077] The catalyst Castel platinum catalyst, the platinum content is 3000pmm;

[0078] Described organic solvent is xylene.

[0079] The above-mentioned preparation method of the PET protective film pressure-sensitive adhesive with high peeling force comprises the steps:

[0080] (1) First mix the base glue, modified MQ resin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com