Preparation method of rubber composition used for automobile and preparation method thereof

A rubber composition, a technology for automobiles, applied in the rubber field, which can solve the problems of poor wear resistance and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

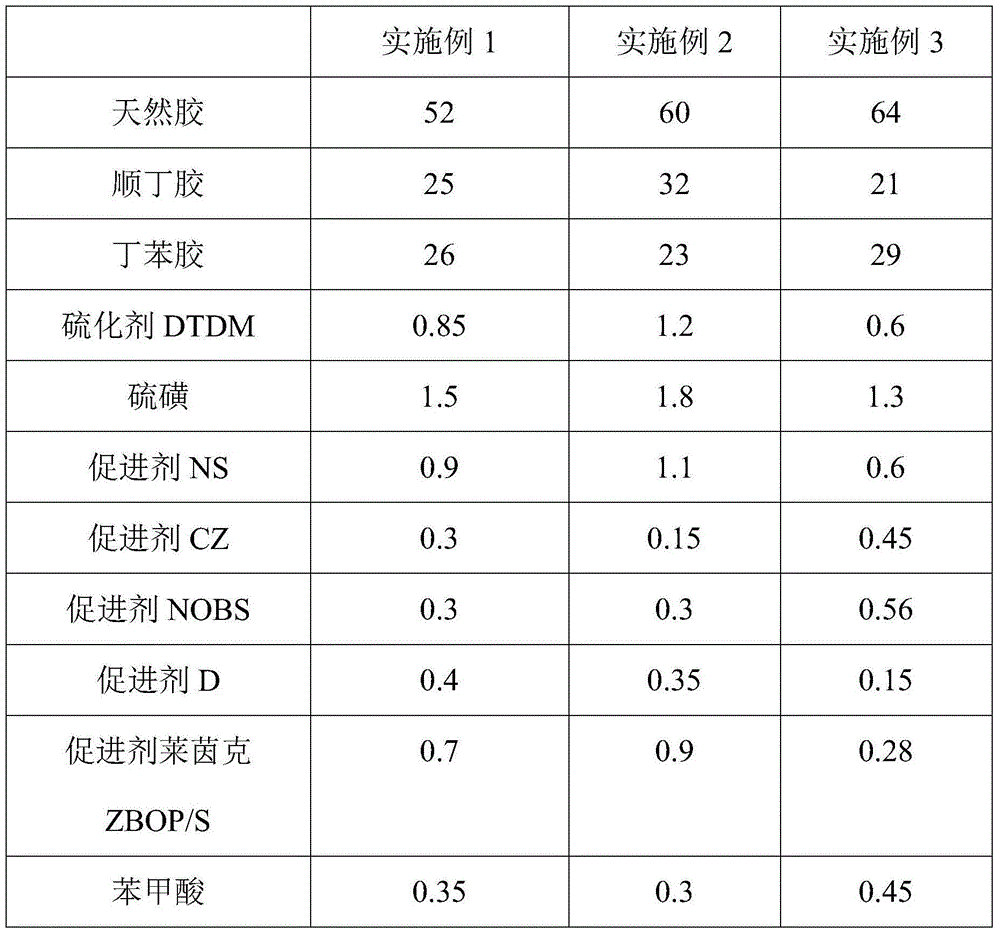

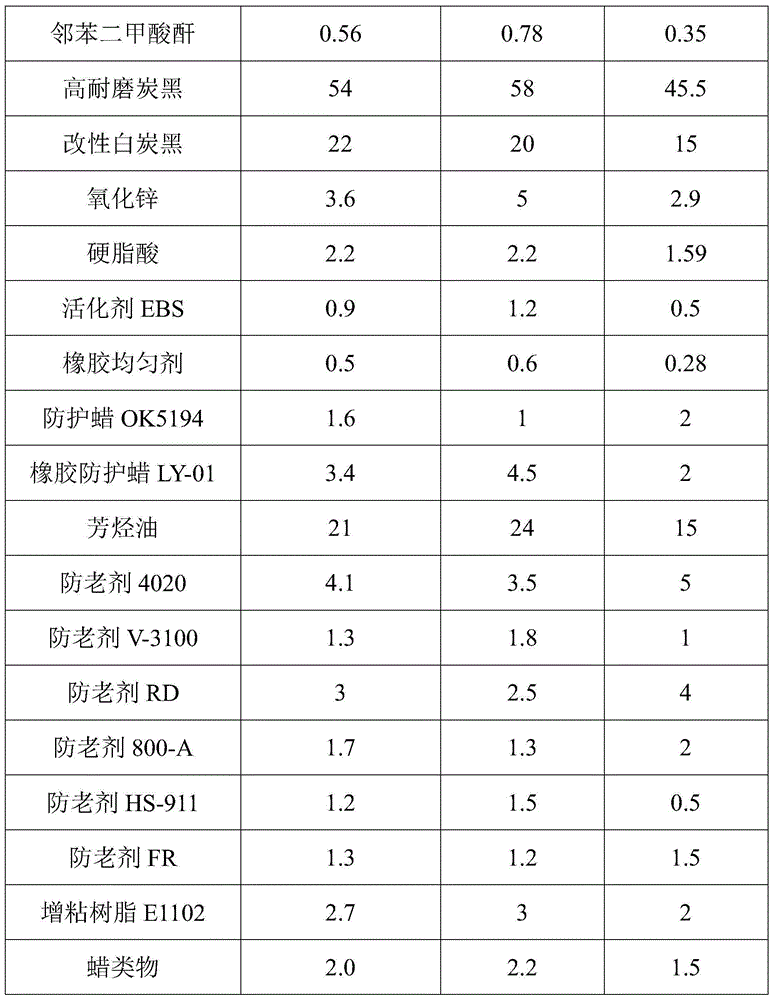

[0022] The preparation method of automobile rubber composition of the present invention, comprises the following steps:

[0023] S1. Weigh each raw material according to the weight and number ratio of Example 1 in Table 1; open the mill, raise the temperature to 32°C, set the roll distance to 0.6mm, and add natural rubber, styrene-butadiene rubber and butadiene rubber at the same time In the open mill, after plasticizing for 14.7 minutes, discharge the glue, pound, press, tablet, cool to room temperature, and park for 3 hours to obtain the plasticized rubber;

[0024] S2. Raise the temperature of the internal mixer to 89°C, adjust the roll distance to 3 mm, add 35% wt of the masticated rubber described in S1, and add the high wear-resistant carbon black and modified white weighed in S1 after mixing for 6 minutes. Carbon black, benzoic acid, phthalic anhydride, rubber leveling agent, tackifying resin E1102, aromatic oil, after mixing for 3.2 minutes, add zinc oxide, stearic aci...

Embodiment 2

[0027] The preparation method of automobile rubber composition of the present invention, comprises the following steps:

[0028] S1. Weigh each raw material according to the ratio of parts by weight; turn on the open mill, raise the temperature to 35°C, set the roll distance to 0.8mm, add natural rubber, styrene-butadiene rubber and butadiene rubber into the open mill at the same time, plastic After refining for 10 minutes, remove the glue, tamping, pressing, tableting, cooling to room temperature, and then park for 3.8 hours to obtain plasticized rubber;

[0029] S2. Raise the temperature of the internal mixer to 82°C, adjust the roll distance to 3.3mm, add 32%wt of the plasticizing rubber described in S1, and add the high wear-resistant carbon black and modified carbon black weighed in S1 after mixing for 8 minutes. Silica, benzoic acid, phthalic anhydride, rubber leveling agent, tackifying resin E1102, aromatic oil, after mixing for 4.8 minutes, add zinc oxide, stearic acid...

Embodiment 3

[0032] The preparation method of automobile rubber composition of the present invention, comprises the following steps:

[0033] S1. Weigh each raw material according to the weight and number ratio of Example 3 in Table 1; open the mill, raise the temperature to 30°C, set the roll distance to 0.7mm, and add natural rubber, styrene-butadiene rubber and butadiene rubber at the same time In the open mill, after plasticizing for 6 minutes, discharge glue, tamping, pressing, tableting, cooling to room temperature, and then park for 4.2 hours to obtain plasticizing rubber;

[0034] S2. Heat up the internal mixer to 85°C, adjust the roll distance to 3.5mm, add 30%wt of the masticated rubber described in S1, and add the high wear-resistant carbon black and modified carbon black weighed in S1 after mixing for 5 minutes. Silica, benzoic acid, phthalic anhydride, rubber leveling agent, tackifier resin E1102, aromatic oil, after mixing for 4.4 minutes, add zinc oxide, stearic acid, activato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com