High-substituted quaternary ammonium polysaccharide bioflocculant and preparation method thereof

A biological flocculant and high degree of substitution technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve problems such as unstable product quality, low reaction conversion rate, high equipment cost, etc., and achieve significant environmental and social benefits, reaction High conversion rate, no three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

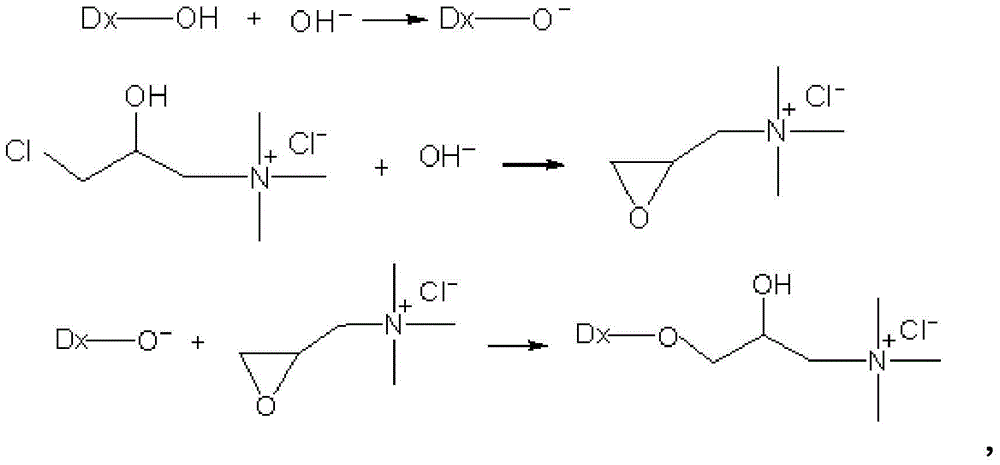

Method used

Image

Examples

Embodiment 1

[0031] ① Alkalinization reaction: Take 200g of non-ionic biological flocculant aqueous solution with a mass concentration of 4% in a 500ml three-necked flask, start stirring, then add 4.5g of sodium carbonate solid, stir and dissolve in a water bath at 30°C, add 9g of urea, and continue stirring for 10min .

[0032] ②Etherification reaction: Slowly add 20ml of isopropanol dropwise to the reaction system in a water bath at 30°C and stir for 0.5h, then evenly sprinkle 16g of 2,3-epoxypropyltrimethylammonium chloride (GTA ), continue stirring reaction 2h.

[0033] ③Product treatment: Take out the reaction product, filter it with filter paper after precipitation, then wash with water, wash with alcohol, dry, and grind to prepare a light yellow quaternary ammonium polysaccharide bioflocculant with a degree of substitution of 1.60.

Embodiment 2

[0035] ① Alkalinization reaction: Take 200g of non-ionic biological flocculant aqueous solution with a mass concentration of 15% in a 500ml three-necked flask, start stirring, then add 8g of sodium oxide solid, stir and dissolve in a water bath at 25°C, and then add 4g of diglycolamine. Continue to stir the reaction for 30min.

[0036] ② Etherification reaction: Slowly add 50 g of 60% 3-chloro-2-hydroxypropyltrimethylammonium chloride (CTA) aqueous solution dropwise into the reaction system, and then continue stirring for 2 hours.

[0037]③Product treatment: The product is a viscous light yellow fluid with a solid content of 31%. After water washing, alcohol washing, drying and grinding, a light yellow quaternary ammonium polysaccharide bioflocculant with a degree of substitution of 0.23 is obtained.

Embodiment 3

[0039] ① Alkalinization reaction: Take 200g of non-ionic biological flocculant aqueous solution with a mass concentration of 16.7% in a 500ml three-necked flask, start stirring, then add 2.8g of sodium hydroxide solid, stir and dissolve in a water bath at 30°C, and then add 2.8g of triethanolamine , continue to stir the reaction for 10min.

[0040] ②Etherification reaction: Slowly add 30ml of acetone to the reaction system, then add 53.44g of 2,3-epoxypropyltrimethylammonium chloride (GTA), and then continue to stir for 1.5h.

[0041] ③Product treatment: The product is a viscous brown-yellow paste with a solid content of 35%. After water washing, alcohol washing, drying and grinding, a light yellow quaternary ammonium polysaccharide bioflocculant with a degree of substitution of 2.41 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com