Lightweight concrete perforated plate profile and its preparation process

A lightweight concrete and perforated plate technology, applied in the field of building materials, can solve the problems of insufficient concrete strength, hollow and porous products or special shapes, water pollution and other problems, saving resources and energy and environmental protection, fully automatic high-quality and high-efficiency , the effect of reducing the building foundation load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this embodiment, the plate profile to be manufactured has a thickness of 80mm and a length of 5m.

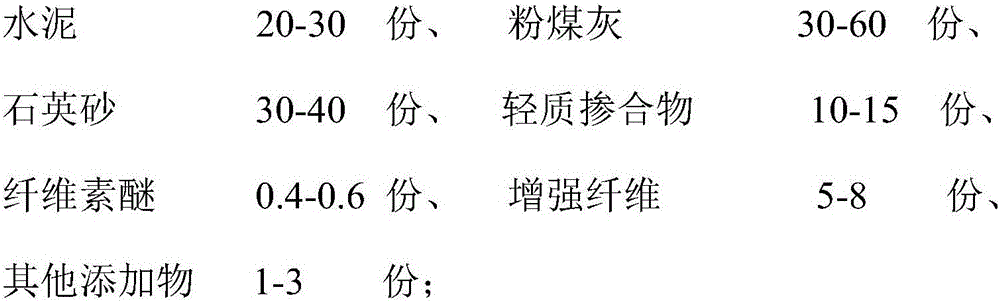

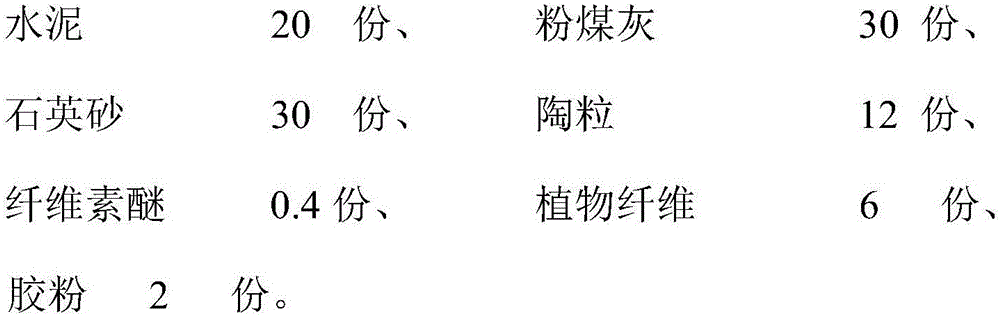

[0027] It uses the concrete mixture as the working masterbatch, and the composition and parts by weight of the raw materials contained in the working masterbatch are:

[0028]

[0029] In the preparation process, the raw materials in the formula are first dry-stirred and mixed for the first time, and then 12 parts of water are added for the second stirring and mixed evenly, and then the vacuum extruder is added with a porous extrusion die Plastic extrusion molding.

[0030] Its specific preparation process steps are as follows:

[0031] a, take the material according to the formula and stir and mix for the first time to prepare the concrete mixture evenly;

[0032] b. According to the high porosity and cross-sectional thickness of the porous plate profile to be manufactured, add cellulose ether and other additives in the concrete mixture according to the proportio...

Embodiment 2

[0040] In this embodiment, the plate profile to be manufactured has a thickness of 200mm and a length of 7m.

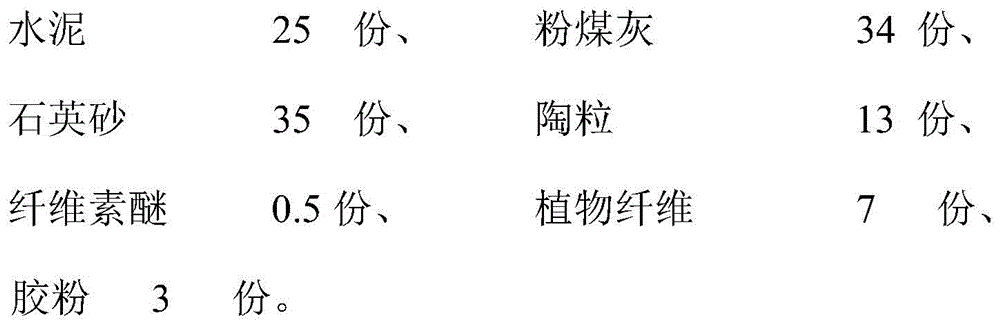

[0041] It uses the concrete mixture as the working masterbatch, and the composition and parts by weight of the raw materials contained in the working masterbatch are:

[0042]

[0043] In the preparation process, the raw materials in the formula are first dry-stirred and mixed for the first time, and then 14 parts of water are added for the second stirring and mixed evenly, and then the vacuum extruder is added with a porous extrusion die Plastic extrusion molding.

[0044] Its specific preparation process steps are as follows:

[0045] a, take the material according to the formula and stir and mix for the first time to prepare the concrete mixture evenly;

[0046] b. According to the high porosity and cross-sectional thickness of the porous plate profile required to be manufactured, add cellulose ether and other additives in the concrete mixture according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com