Graphite electrode with diameter of 348 mm and manufacture method thereof

A technology of graphite electrodes and graphite chips, applied in the field of graphite electrodes, can solve problems such as high strength and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

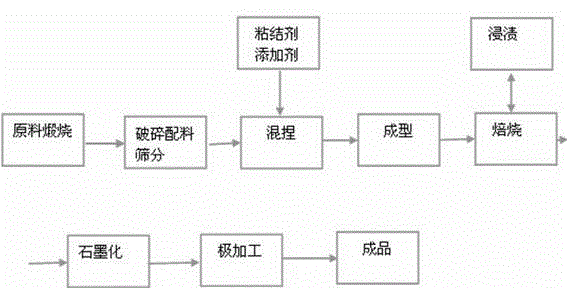

Method used

Image

Examples

preparation example Construction

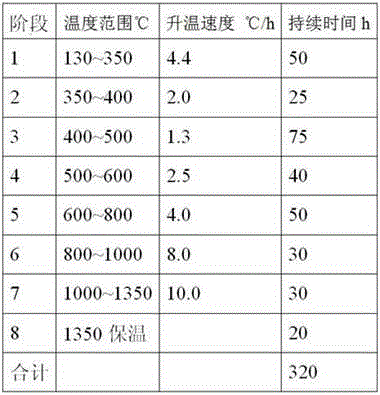

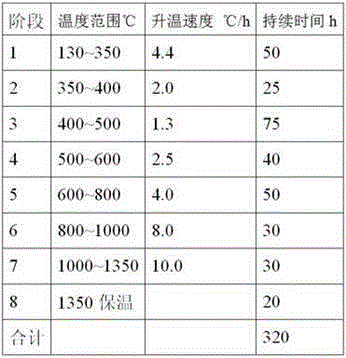

[0015] A kind of preparation method of diameter 348mm graphite electrode its preparation method is as follows:

[0016] (1) Calcination: Three kinds of high-quality petroleum cokes from Fushun, Tianjin and Jinzhou are mixed and crushed according to the ratio of 40~60%, 20~30%, 20~30%, and then calcined. The calcination temperature is 1250℃~1350℃. Density ≥ 2.08g / ㎝3, powder resistivity ≤ 500μΩm;

[0017] (2) Ingredients: Mix the petroleum coke calcined in step (1) and the domestic needle coke at a ratio of 70-80% and 20-30%, crush and sieve to obtain dry materials of different particle sizes, according to the following weight Percentage composition for batching: 18~25% of mixed petroleum coke with medium particle size of 2~0.5mm, 18~25% of mixed petroleum coke with small particle size below 0.5mm, 48~55% of powder with particle size of 0.074mm, and 5~12% of graphite powder with particle size below 2mm %; Finally, adding 10-25% of the total weight of dry material raw crushed; ...

Embodiment 1

[0029] The graphite electrode with a diameter of 348 mm in this embodiment is mainly composed of high-quality mixed petroleum coke as raw material of different particle sizes. 18% of petroleum coke, 55% of 0.074mm powder, and 9% of graphite fragments with a particle size of 2mm or less; add 24% of the binder in the dry material, and add 0.3% of stearic acid in the dry material; Add raw ground 10% by total weight of dry ingredients.

[0030] The preparation method of the 348mm diameter graphite electrode of the present embodiment is as follows:

[0031] (1) Calcination: Mix and crush three high-quality petroleum cokes from Fushun, Tianjin and Jinzhou in proportions of 40%, 30% and 30%, and then calcinate. Resistivity≤500μΩm;

[0032] (2) Ingredients: Mix the petroleum coke calcined in step (1) and domestic needle coke at a ratio of 70% and 30%, grind and sieve to obtain dry materials of different particle sizes, and mix according to the following weight percentage composition...

Embodiment 2

[0038] The graphite electrode with a diameter of 348 mm in this embodiment mainly consists of high-quality mixed petroleum cokes of different particle sizes as raw materials. The composition of the dry materials is: 25% of mixed petroleum coke with a medium particle size of 0.5 mm, and small particle sizes below 0.5 mm. 18% of mixed petroleum coke, 52% of 0.074mm powder, and 5% of graphite fragments with a particle size of less than 2mm; add 28% of the binder in the dry material, and add 0.5% of stearic acid in the dry material ; Add 25% of the total weight of the dry ingredients raw mince.

[0039] The preparation method of the 348mm diameter graphite electrode of the present embodiment is as follows:

[0040] (1) Calcination: Mix three kinds of high-quality petroleum cokes from Fushun, Tianjin and Jinzhou according to the proportion of 60%, 20% and 20%, and then calcine them. Resistivity≤500μΩm;

[0041] (2) Ingredients: Mix the petroleum coke calcined in step (1) and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com