Method for measuring volatile fragrance components of electronic cigarette

A technology of aroma components and determination methods, which is applied in the field of analysis and determination, can solve the problems of lack of comprehensive understanding, lack of quality control of electronic cigarettes, and lack of determination and analysis methods of volatile aroma components of electronic cigarettes, so as to save analysis costs, The effect of low detection limit and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

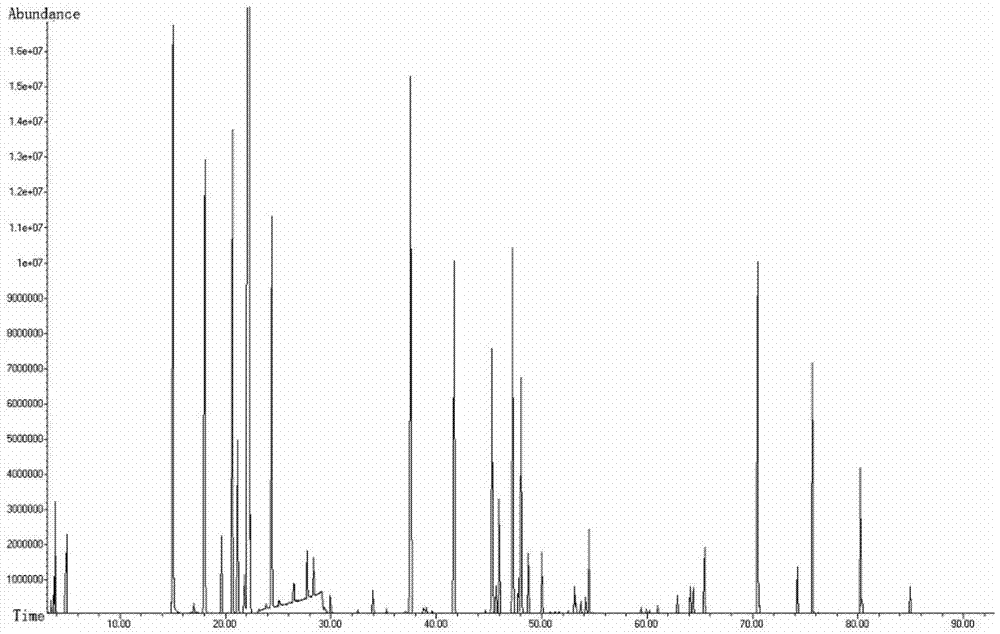

Embodiment 1

[0023] 1) Take 2 mL of e-cigarette liquid of a certain brand and place it in a 20 mL headspace sampling bottle, add 4 mL of dichloromethane (chromatographically pure) and mix well, then seal the mouth of the headspace sampling bottle with a bottle cap;

[0024] 2) Insert the solid-phase microextraction needle with the fiber tip into the gas chromatographic inlet, and perform aging treatment on the fiber tip for 25 minutes at 260°C, with a carrier gas volume flow rate of 1.0mL / min; the fiber tip is 65 μm dimethyl Silicone / divinylbenzene (PDMS / DVB);

[0025] 3) Insert the solid-phase microextraction needle with the fiber head into the upper space of the headspace sampling bottle through the bottle cap, and carry out the headspace solid-phase analysis on the volatile aroma components of the e-cigarette liquid in step 1) under the following conditions: Micro-extraction: keep at 80°C for 5min, absorb at 80°C for 30min, and rotate at 250rpm;

[0026] 4) Desorb the substance extract...

Embodiment 2

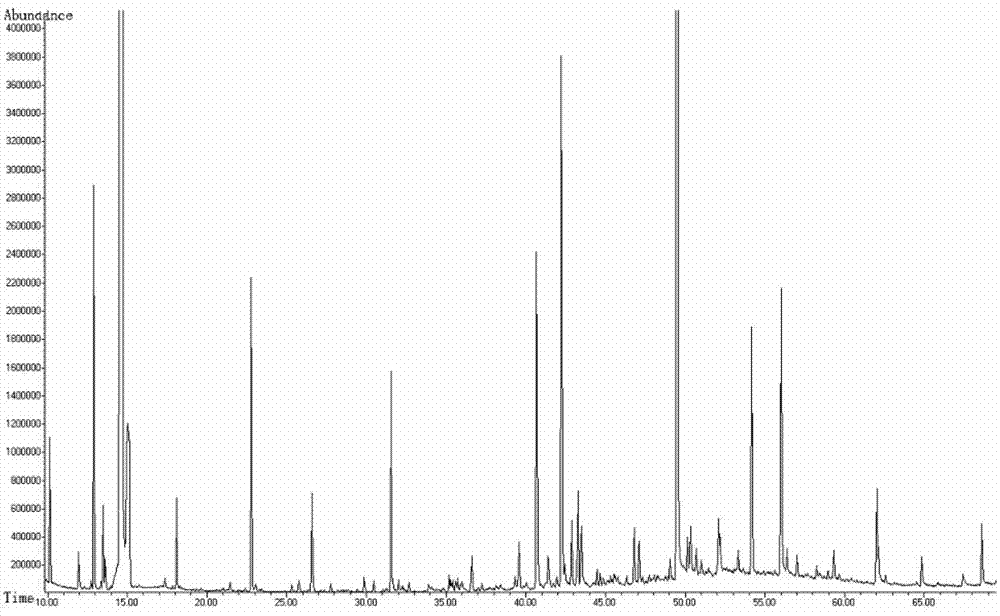

[0034] 1) Take a certain brand of disposable electronic cigarette, cut the electronic cigarette vertically, use tweezers to completely take out the glass wool soaked in the liquid in the atomizer (the amount of liquid is 1 gram), put it into a 25mL conical flask, Add 10 mL of dichloromethane (chromatographically pure), cap the bottle, and conduct ultrasonic extraction at 25°C for 30 minutes, then pipette 6 mL of the extraction solution into a 20 mL headspace sampling bottle, and seal the mouth of the headspace sampling bottle with the bottle cap;

[0035] 2) Insert the solid-phase microextraction needle with the fiber tip into the gas chromatographic inlet, and perform aging treatment on the fiber tip for 30 minutes at 270°C, with a carrier gas volume flow rate of 1.0mL / min; the fiber tip is 100μm polydimethylformaldehyde polysiloxane (PDMS);

[0036] 3) Insert the solid phase microextraction needle with the fiber head into the space above the headspace sampling bottle through...

Embodiment 3

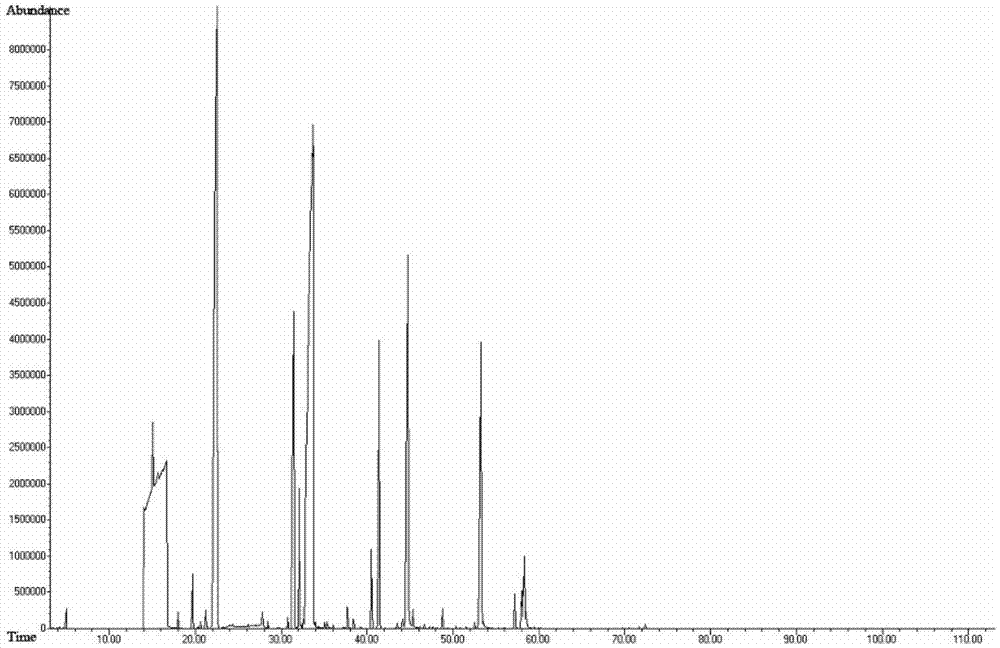

[0045] 1) Take 3mL of a certain brand of e-cigarette liquid into a 30mL headspace sampling bottle, add 6mL of n-hexane (chromatographically pure) and mix well, then seal the mouth of the headspace sampling bottle with a bottle cap;

[0046] 2) Insert the solid-phase microextraction needle with the fiber tip into the gas chromatographic inlet, and perform aging treatment on the fiber tip for 30 minutes at 260°C, with a carrier gas volume flow rate of 1.0mL / min; the fiber tip is a 50μm divinyl Benzene / carboxyethyl / polydimethylsiloxane (DVB / CAR / PDMS);

[0047] 3) insert the solid-phase microextraction needle with fiber head into the space above the headspace bottle through the bottle cap, and carry out headspace solid-phase microextraction to the volatile aroma components of the extraction solution of step 1) under the following conditions: 100 Keep at ℃ for 4 minutes, adsorb at 100℃ for 10 minutes, and rotate at 250rpm;

[0048] 4) The extracted substance is desorbed at the gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionization potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com