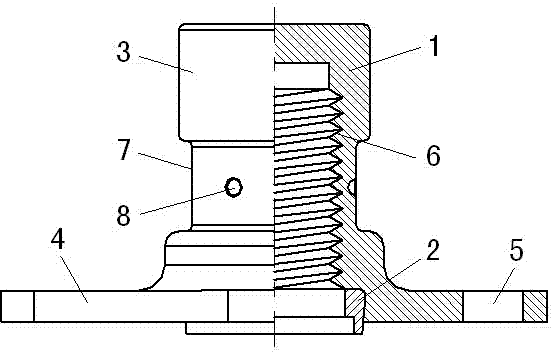

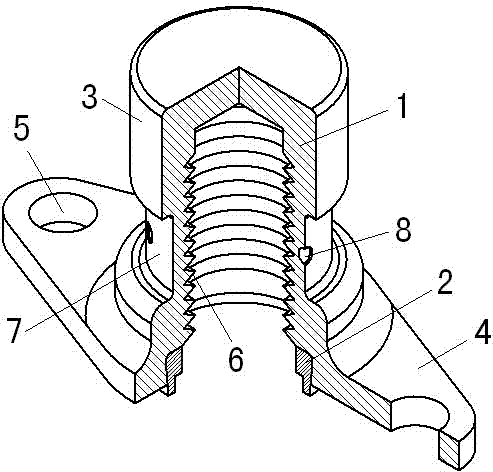

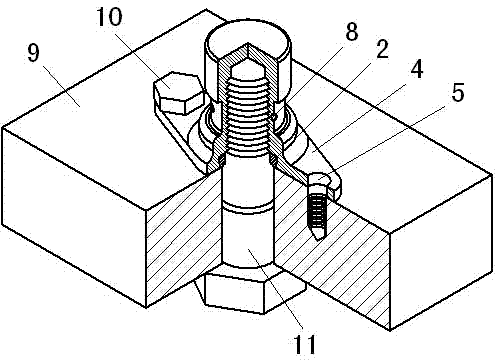

Sealing self-locking nut assembly and manufacturing method

A technology of self-locking nuts and production methods, which is applied in the direction of nuts, threaded fasteners, locking fasteners, etc., can solve the problems that cannot meet the needs of aircraft and submersibles, achieve good sealing, prevent loosening, and improve reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] During specific implementation, the shape blank can be directly molded or forged by a bar with better plasticity, and then formed by mechanical finishing. Due to the use of advanced high-tech materials, the strength and plasticity of the material are excellent. After molding or forging, the crystal grains are not broken and are streamlined, that is, the grain streamlines are uniform, complete and highly oriented. The material is produced by molding or forging After cold work hardening, its tensile strength and fatigue strength are greatly enhanced, and shape memory alloys can also be used, molded at high temperatures and rapidly cooled to obtain blanks of any shape. In addition to the above-mentioned shape memory alloys, materials with strength greater than 1100MPa and excellent plasticity can also be used, such as high-strength forgings, high-temperature alloys, titanium alloys, high-strength steels, ultra-high-strength steels and some special steels. During specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com