Cyanide-free monovalent copper preimpregnation method for iron and steel parts or zinc alloy die-casting parts

A zinc alloy and die-casting technology, applied in metal material coating process, liquid chemical plating, coating and other directions, can solve the problems of poor copper coating adhesion, improve the adhesion of the coating, reduce the concentration, and reduce the discharge potential. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

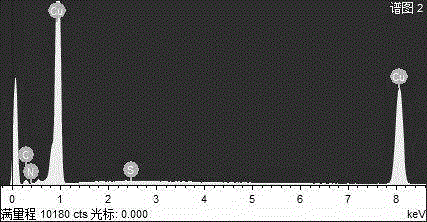

Image

Examples

specific Embodiment approach 1

[0014] Specific implementation mode one: the iron and steel parts or zinc alloy die-casting parts of the present embodiment method is carried out according to the following steps:

[0015] (1) Preparation of cyanide-free monovalent copper immersion plating solution: a. The concentration of monovalent copper compound is 2~40g / L, the concentration of antioxidant is 2~30g / L, and the concentration of non-cyanide main complexing agent is 10~130g / L, the concentration of auxiliary complexing agent is 5~60g / L, and the concentration of buffering agent is 5~40g / L. Weigh the monovalent copper compound, antioxidant, non-cyanide main complexing agent, auxiliary complexing agent b. the antioxidants taken by step a are dissolved in the hydrochloric acid solution of 60mL / L, then the non-cyanide main complexing agent and auxiliary complexing agent taken by step a are added, and under the condition of heating Stir until dissolved to prepare solution A; c. Slowly add the monovalent copper compou...

specific Embodiment approach 2

[0019] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the monovalent copper compound described in a and c of step (1) is one of cuprous oxide, cuprous chloride or cuprous bromide , the concentration is 3~35g / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the antioxidant described in step (1) a and b is hydroquinone, pyrocatechol, resorcinol, sub- One or a combination of sodium phosphate, uric acid or ascorbic acid, the concentration is 3~25g / L. Others are the same as in the first or second embodiment.

[0021] When the antioxidant of this embodiment is a composition, various antioxidants are combined in arbitrary ratios.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com