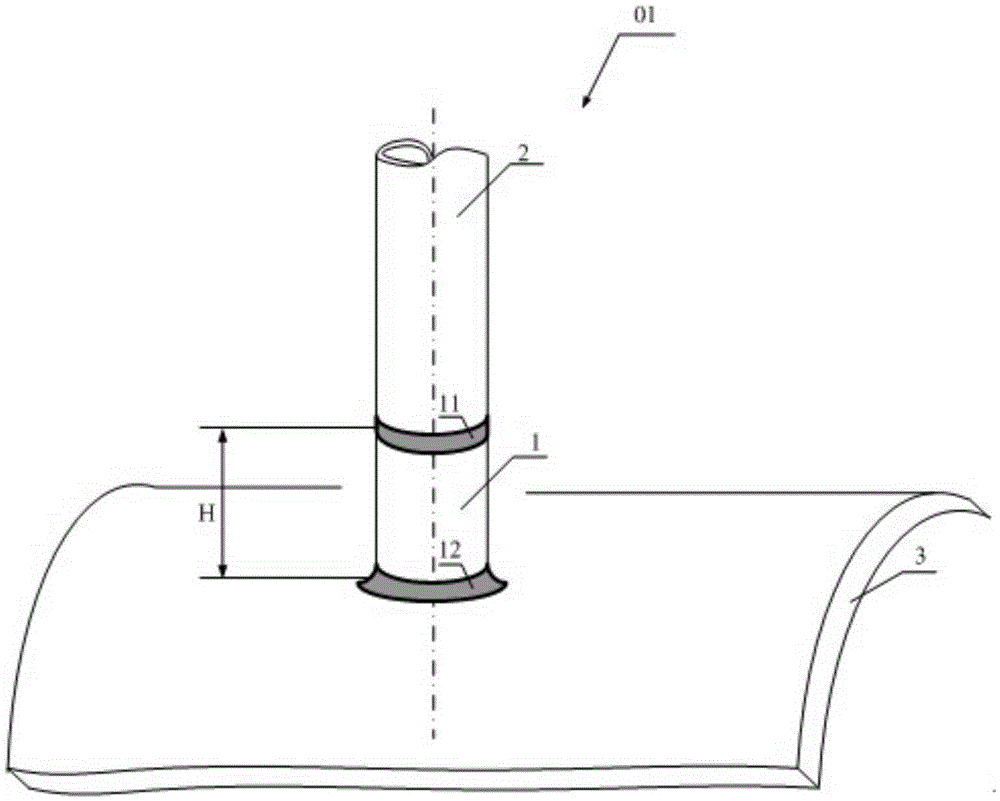

Partial post-weld heat treatment method for butt joint of connecting pipe seat

A butt joint and post-heat treatment technology, which is applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve the problems of deteriorating heat treatment temperature field, increasing joint residual stress, and joint performance damage, so as to overcome adverse effects and avoid additional The effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

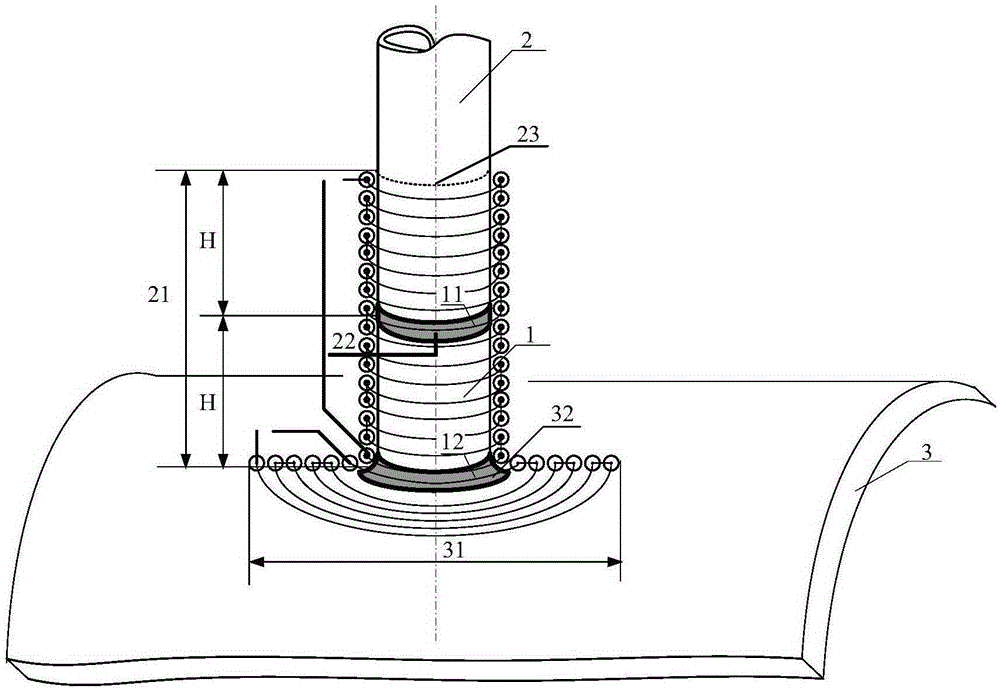

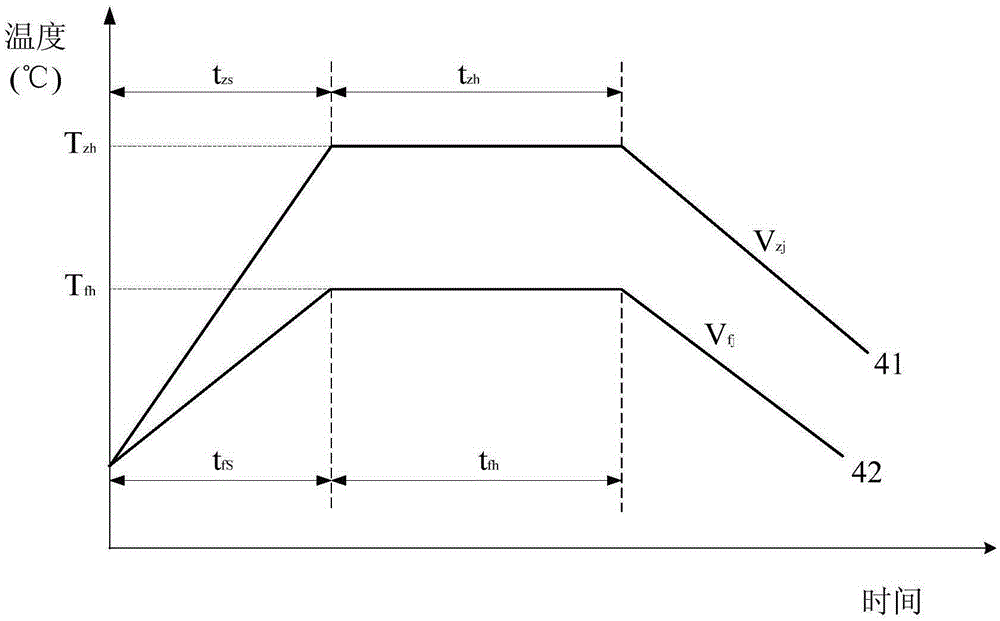

[0080] The cylinder material of a header is P91 steel, the material of the connecting seat is T91, the specification of the connecting seat is OD63.5×18 (mm), the height of the connecting seat is 90mm, the material of the pipe connected to the connecting seat is T91 steel, and the specification is OD63. 5×18 (mm). The welding process requires post-weld heat treatment for the butt joint of the nozzle seat. The given process parameters for post-weld heat treatment are: constant temperature 750°C, constant temperature time 2h, time from room temperature to constant temperature 2.5h, cooling from constant temperature The cooling rate to 300°C is 300°C / h.

[0081] Using the method of the present invention to carry out post-weld heat treatment on the butt joint of the socket, the specific implementation steps are as follows:

[0082] (1) Arrangement of thermocouples: Arrange one thermocouple on the butt weld as the temperature control thermocouple of the main heating device; arrang...

Embodiment 2

[0092] A nozzle socket on a steam drum body has been repaired by welding. After the repair, post-weld heat treatment is required for the butt joint of the nozzle socket. The material of the steam drum body is SA299, the material of the connecting seat is 20MnMo, the specification of the connecting seat is OD273×28(mm), and the length of the connecting seat is 100mm; the material of the pipe is 20G, and the specification is OD273×22(mm). The given post-weld heat treatment process parameters are: constant temperature temperature 600°C, constant temperature time 1.5h, time for heating from room temperature to constant temperature is 2h, time for cooling from constant temperature to 300°C is 1.0h.

[0093] Using the method of the present invention to carry out post-weld heat treatment on the butt joint of the socket, the specific implementation steps are as follows:

[0094] (1) Arrangement of thermocouples: Arrange one thermocouple on the butt weld as the temperature control ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com