Local postweld heat treatment method for three-way branch pipe butt joint

A technology for butt joints and post-heat treatment, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., which can solve problems such as deteriorating temperature field, adverse effects on joint performance and life, and joint scrapping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

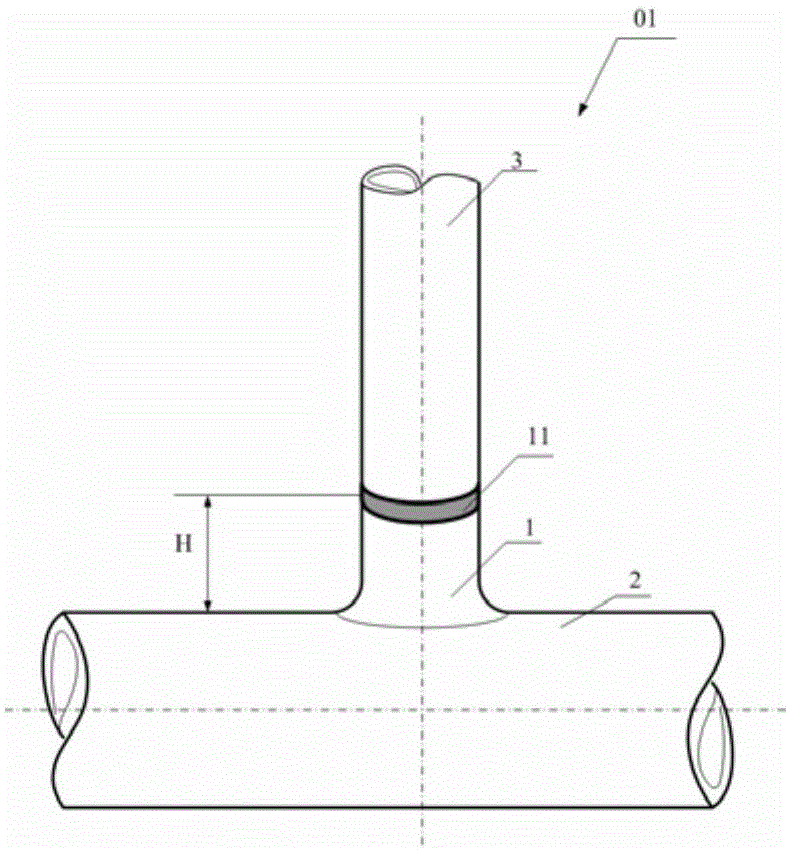

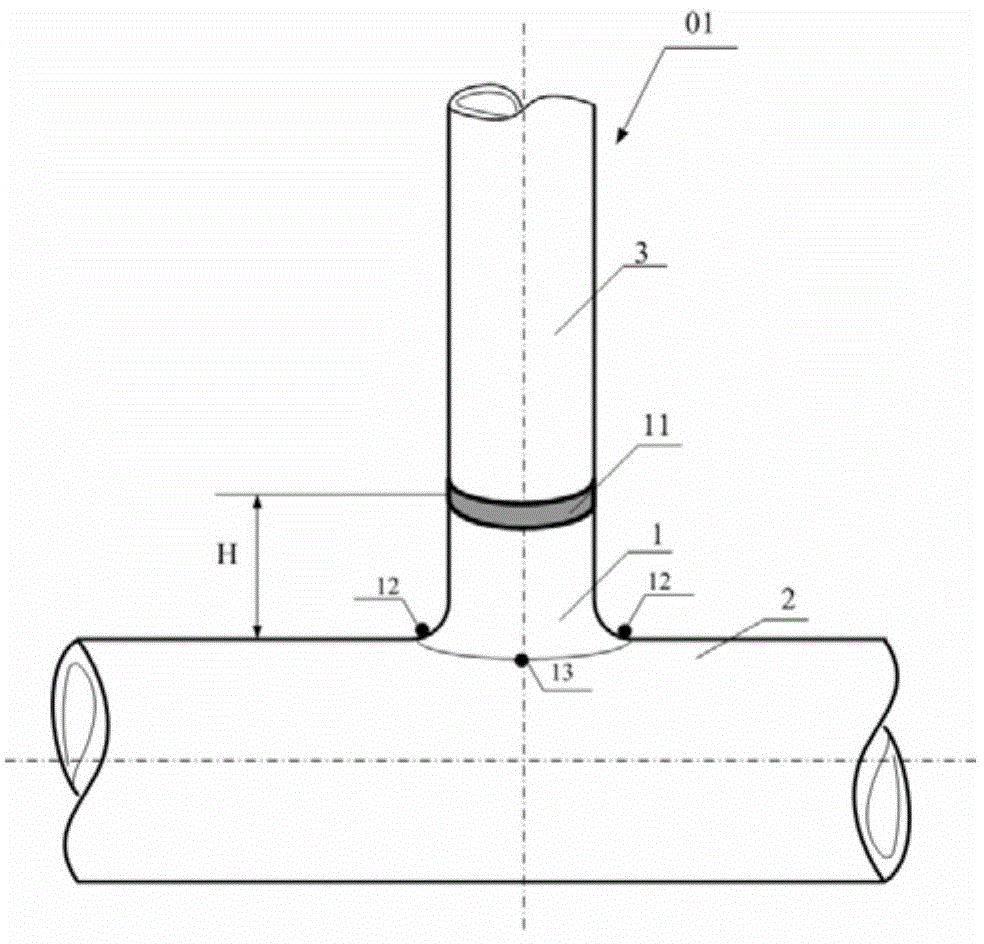

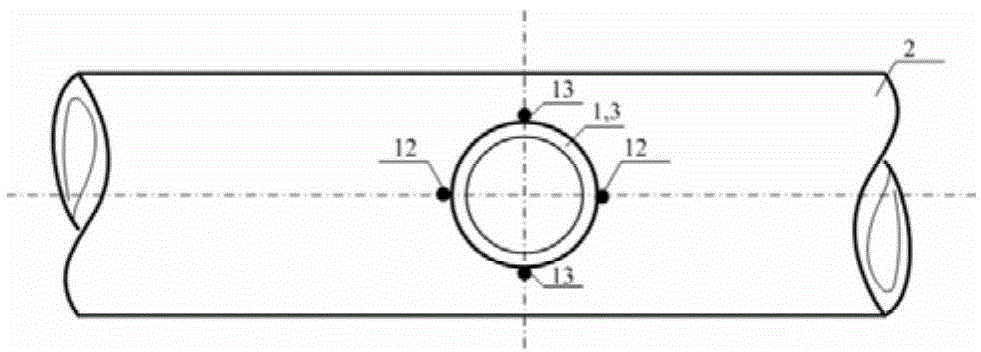

[0059] Such as Figure 1 to 6 As shown, the butt joint 01 of the three-way branch pipe includes a weld 11 connecting the branch pipe 1, the main pipe 2, the pipe 3, the branch pipe 1 and the pipe 3. When performing post-weld heat treatment on the butt joint 01 of the three-way branch pipe, the main heating device 21 (heating rope, heating plate, etc.) shall be symmetrically arranged at the two ends of the welding seam 11 with equal power and equal width, and the layout width of each end is equal to the branch pipe 1. The height H. A thermocouple is arranged at the welding seam position 24 opposite to the apex 13 of the three-way abdomen as the temperature control thermocouple 20 of the main heating device 21. At the end of the main heating device, a thermocouple is set at a position 23 opposite to the apex of the tee abdomen, which serves as the temperature measuring thermocouple 22 at the end of the main heating device 21; with the branch pipe 1 as the center, the auxiliary h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com