Discharge aiding agent of fracture acidizing nanoemulsion and preparation method of discharge aiding agent

A nano-emulsion, fracturing and acidizing technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as inability to overcome water lock damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

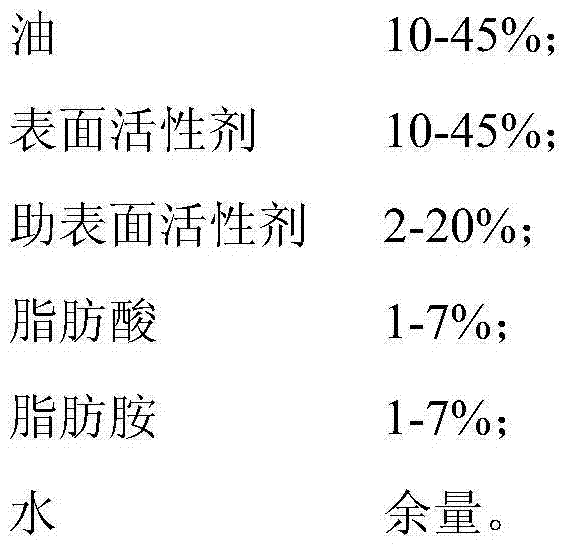

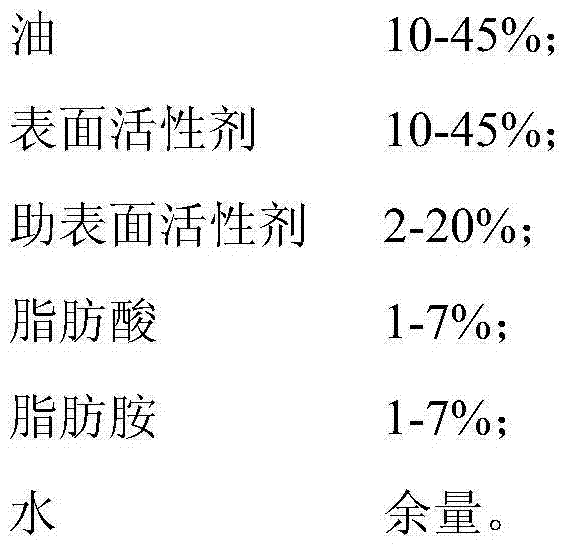

[0029] This embodiment provides a concentrated solution of a fracturing and acidifying nanoemulsion drainage aid. In terms of weight percentage, its raw material composition includes:

[0030] D-limonene oil 45%, non-ionic surfactant isotridecyl alcohol polyoxypropylene (4) polyoxyethylene (6) ether 35%, isopropanol 8%, oleic acid amine 2.6%, oleic acid 1.3%, The balance is water.

[0031] The concentrate is prepared by the following steps:

[0032] Mix D-limonene oil, nonionic surfactant isomeric tridecyl alcohol polyoxypropylene (4) polyoxyethylene (6) ether, isopropanol, oleic acid amine, oleic acid, then add water to balance to 100%, Mix well to obtain a concentrate.

Embodiment 2

[0034] This embodiment provides a fracturing and acidifying nanoemulsion drainage aid, which is a uniform transparent or light blue nanoemulsion obtained by diluting the concentrated solution of Example 1 with KCl water with a concentration of 2wt%. The size of the nanoemulsion is determined by dynamic laser scattering: the diameter of the liquid particles is between 20-100 nanometers.

Embodiment 3

[0036] Flowback efficiency test:

[0037] Using the nanoemulsion of Example 2 as a drainage aid, fill 20-40 mesh quartz sand into a sand-filling tube with a length of 25 cm and a diameter of 2.5 cm, vibrate up and down 200 times to keep the permeability basically consistent each time. The nanoemulsion to be tested is injected into the sand filling pipe, the lower valve is opened to allow the liquid to flow out under the action of gravity, the amount of liquid flowing out is recorded, and the flowback efficiency is calculated to be 76%.

[0038] Compared with the flowback efficiency of water without nanoemulsion, which is 57%, and the flowback efficiency without fatty acid and fatty amine is 70%, it can be seen that adding fatty acid and fatty amine can further improve the flowback rate of nanoemulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com