High-strength powder paint

A powder coating, high-strength technology, applied in the direction of powder coating, epoxy resin coating, coating, etc., can solve the problems of low energy consumption, mechanical properties can not meet the expected requirements, etc., to achieve increased strength, good leveling, The effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

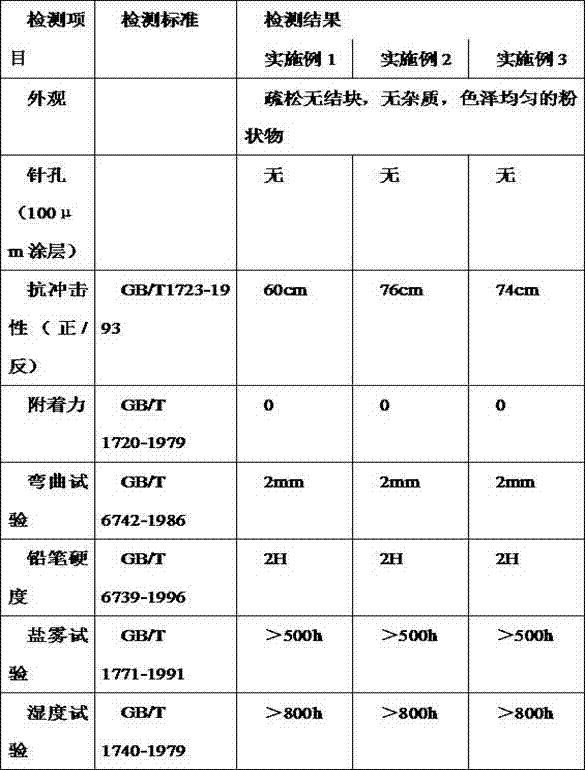

Examples

Embodiment 1

[0010] A high-strength powder coating, its composition and weight ratio are: epoxy resin E-12 40%, hydroxyl acrylic resin 8%, EVA resin 6%, titanium dioxide 15-20%, barium sulfate 20%, curing agent TEFC 4%, leveling agent 0.5%, brightener 0.5%, pigment and filler 1%.

Embodiment 2

[0012] A high-strength powder coating, its composition and weight ratio are: epoxy resin E-12 41%, hydroxyl acrylic resin 10%, EVA resin 4%, titanium dioxide 15%, barium sulfate 24%, curing agent TEFC 3 %, leveling agent 1%, brightener 1%, pigment and filler 1%.

Embodiment 3

[0014] A high-strength powder coating, its composition and weight ratio are: epoxy resin E-12 33%, hydroxyl acrylic resin 10%, EVA resin 6%, titanium dioxide 17%, barium sulfate 24%, curing agent TEFC 6 %, leveling agent 1.5%, brightener 1.5%, pigment and filler 1%.

[0015] Production Process:

[0016] (1) Mixing, the raw materials were mixed according to the proportions of Examples 1-3, and mixed at 600rpm for 5min;

[0017] (2) Extrusion, melt extrusion through a screw extruder, the temperature control of the three zones of the extruder is: zone one: 60°C, zone two: 95°C, zone three: 120°C;

[0018] (3) Grinding. The molten material is pressed into tablets by a tablet press, and the thickness is controlled at 3 mm. After being crushed, it is sent to a mill for crushing and grading. After passing through a 160-mesh sieve, the fluidity of the powder is not less than 160.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com