Scratch-resistant PE (polyethylene) film packaging material and preparation method thereof

A film packaging and scratch-resistant technology, which is applied in the field of packaging materials, can solve the problems of limiting the application range of PVC material films, poor stability of PVC materials, and decreased mechanical strength, so as to achieve the effect of protecting the appearance quality, making it convenient, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Dry the PE resin, polyvinyl alcohol, vinyl bis-stearamide and glycerol for use;

[0031] (2) 50kg of PE resin, 20kg of polyvinyl alcohol, 2kg of polyvinylidene fluoride, 5kg of zinc stearate and 0.5kg of vinyl bis-stearamide were weighed and poured into the reactor at 300 rpm, stirred for 15min, heated to 110 ° C, pressurized 0.5 MPa, and reacted for 3 h to obtain a polymer melt;

[0032] (3) adding glycerol 0.5kg in the product of step 2, then extruding, dicing and drying to obtain polyester chips;

[0033] (4) The polyester chips of step 3 are melted and extruded at 260°C, cast and rolled, biaxially stretched, cooled and shaped to obtain a scratch-resistant PE film packaging material, and the biaxial stretching temperature is 110°C.

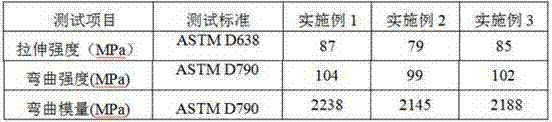

[0034] The performance test results of the scratch-resistant PE film packaging materials are shown in Table 1.

Embodiment 2

[0036] (1) Dry the PE resin, polyvinyl alcohol, vinyl bis-stearamide and glycerol for use;

[0037] (2) Weighing 80kg of PE resin, 30kg of polyvinyl alcohol, 6kg of fluorinated ethylene propylene, 1kg of zinc stearate and 2kg of vinyl bis-stearamide, poured into the reactor at 350 rpm, stirred for 10min, heated to 150 ℃, pressurized 0.5MPa, and reacted for 2h to obtain a polymer melt;

[0038] (3) adding 1kg of glycerol in the product of step 2, then extruding, dicing and drying to obtain polyester chips;

[0039] (4) The polyester chips of step 3 are melted and extruded at 270°C, cast and rolled, biaxially stretched, cooled and shaped to obtain a scratch-resistant PE film packaging material, and the biaxial stretching temperature is 115°C.

[0040] The performance test results of the scratch-resistant PE film packaging materials are shown in Table 1.

Embodiment 3

[0042] (1) Dry the PE resin, polyvinyl alcohol, vinyl bis-stearamide and glycerol for use;

[0043] (2) 60kg of PE resin, 15kg of polyvinyl alcohol, 10kg of ethylene tetrafluoroethylene copolymer, 3kg of zinc stearate and 1kg of vinyl bis-stearamide were weighed and poured into the reaction kettle at 200 rpm, stirred for 20min, and heated. to 130°C, pressurized 0.5MPa, and reacted for 3h to obtain a polymer melt;

[0044] (3) adding 2kg of glycerol in the product of step 2, then extruding, dicing and drying to obtain polyester chips;

[0045] (4) The polyester chips of step 3 are melted and extruded at 280°C, cast and rolled, biaxially stretched, cooled and shaped to obtain a scratch-resistant PE film packaging material, and the biaxially stretched temperature is 110°C.

[0046] The performance test results of the scratch-resistant PE film packaging materials are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com