Method for preparing aucubin monomer from eucommia ulmoides fruit

The invention relates to a technology of aucubin and a processing method, which are applied in the field of medicine and can solve the problems of unfavorable industrial production, development and utilization of aucubin monomer, long industrial production cycle, large consumption of reagents, and the like, so as to improve the comprehensive utilization rate. , to achieve the effect of effective use and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

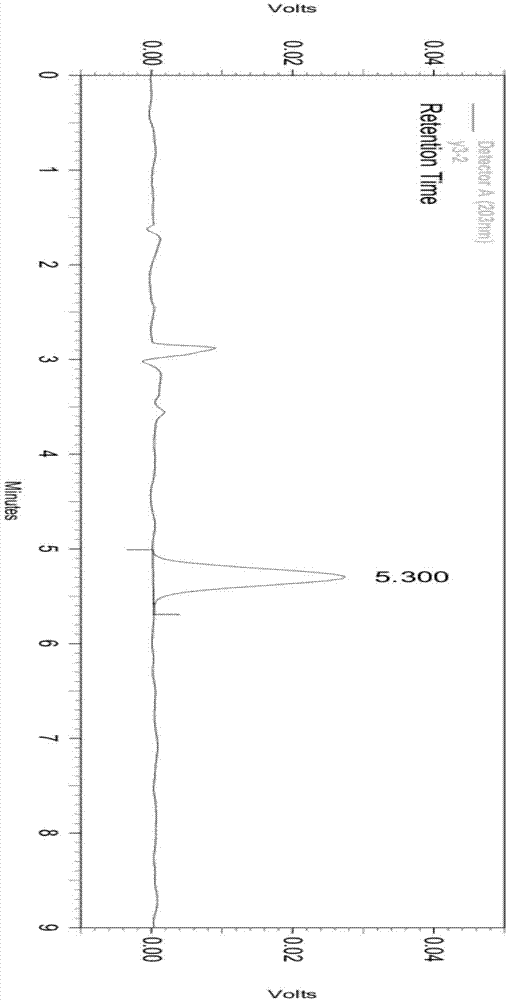

Embodiment 1

[0035] Shell the eucommia fruit, crush the nuts to 40 mesh, take 10kg and put it into the extraction tank, add 60L petroleum ether to degrease, degrease twice, each time for 3 hours, and filter out the dregs as degreasing coarse material. Add 80L of ethanol to ultrasonically extract the defatted crude material for 2 hours, extract 3 times, and combine the extracts. The extract was concentrated under reduced pressure at 40°C to 1 / 8 of the original volume and ethanol was recovered. The concentrated solution was saturated with acetone and dissolved, crystallized at 7°C for 48 hours, and the crude crystals were saturated with ethyl acetate and dissolved. Get 10L silica gel packing column, add saturated liquid to silica gel column, use 3BV ethyl acetate (mass ratio ethyl acetate:methanol=1:0) successively, 4BV10:1 ethyl acetate / methanol (mass ratio ethyl acetate:methanol= 10:1), 5BV6:1 ethyl acetate / methanol (mass ratio ethyl acetate:methanol=6:1), 4BV4:1 ethyl acetate / methanol so...

Embodiment 2

[0037]Shell the eucommia fruit, crush the nuts to 50 mesh, take 10kg and put it into the extraction tank, add 80L petroleum ether to degrease, degrease 3 times, each time for 4 hours, filter out the dregs as degreasing coarse material. Add 100L of ethanol to ultrasonically extract the defatted crude material for 4 hours, extract 5 times, and combine the extracts. The extract was concentrated under reduced pressure at 40°C to 1 / 10 of the original volume and ethanol was recovered. The concentrated solution was saturated with acetone and dissolved, crystallized at 4°C for 72 hours, and the crude crystals were saturated with ethyl acetate and dissolved. Get 10L silica gel packing column, add saturated liquid to silica gel column, use 3BV ethyl acetate (mass ratio ethyl acetate:methanol=1:0) successively, 4BV10:1 ethyl acetate / methanol (mass ratio ethyl acetate:methanol= 10:1), 5BV6:1 ethyl acetate / methanol (mass ratio ethyl acetate:methanol=6:1), 4BV4:1 ethyl acetate / methanol sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com