Straight grinding machine for steel bridge testing and with telescopic grinding heads

A technology of grinding head and straight grinding machine, which is applied in the direction of grinding head, machine tool suitable for grinding the edge of workpiece, and machine tool designed for grinding the rotating surface of workpiece, etc., which can solve the inconvenience of grinding, time-consuming grinding, unfavorable operation, etc. problems, to achieve the effect of convenient operation and improved grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

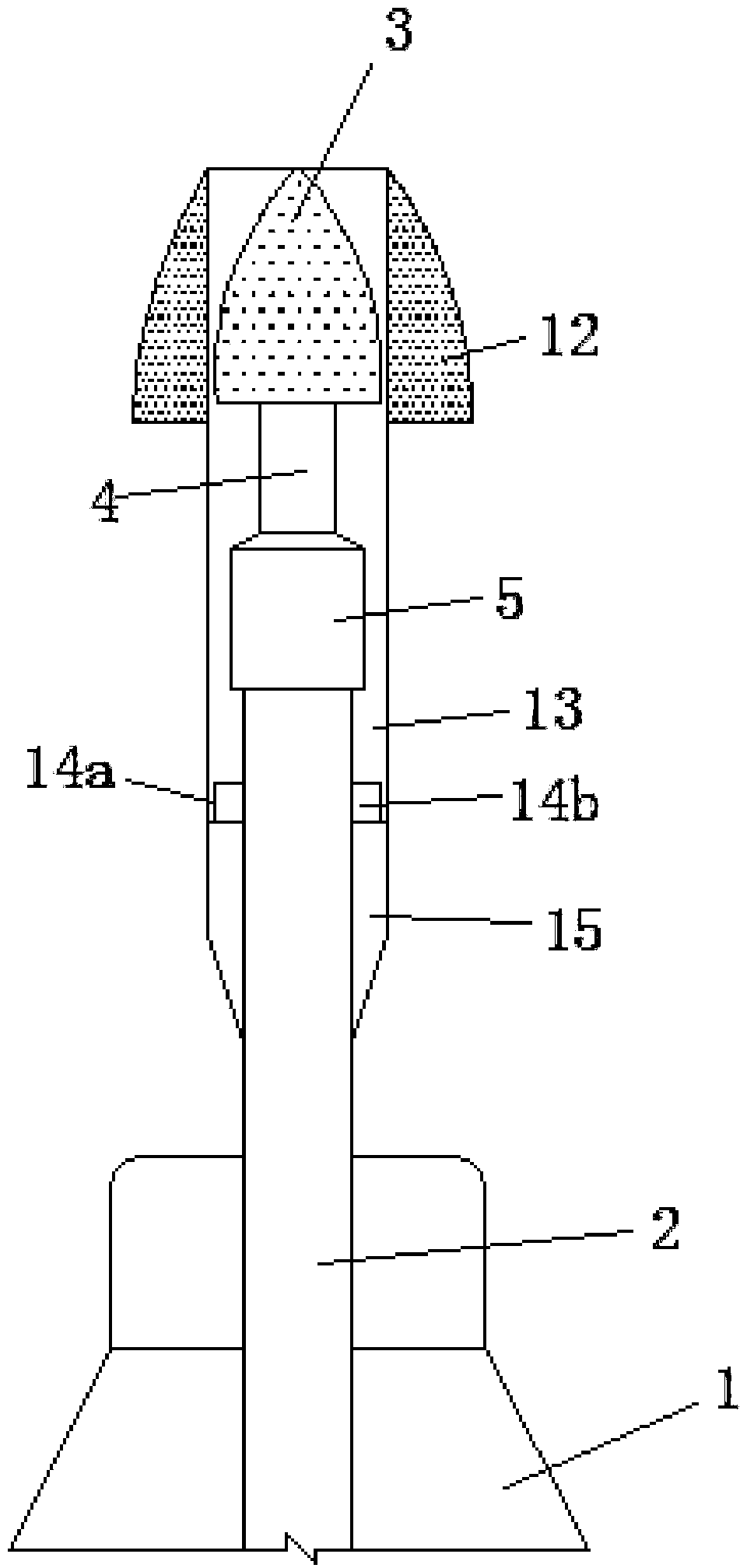

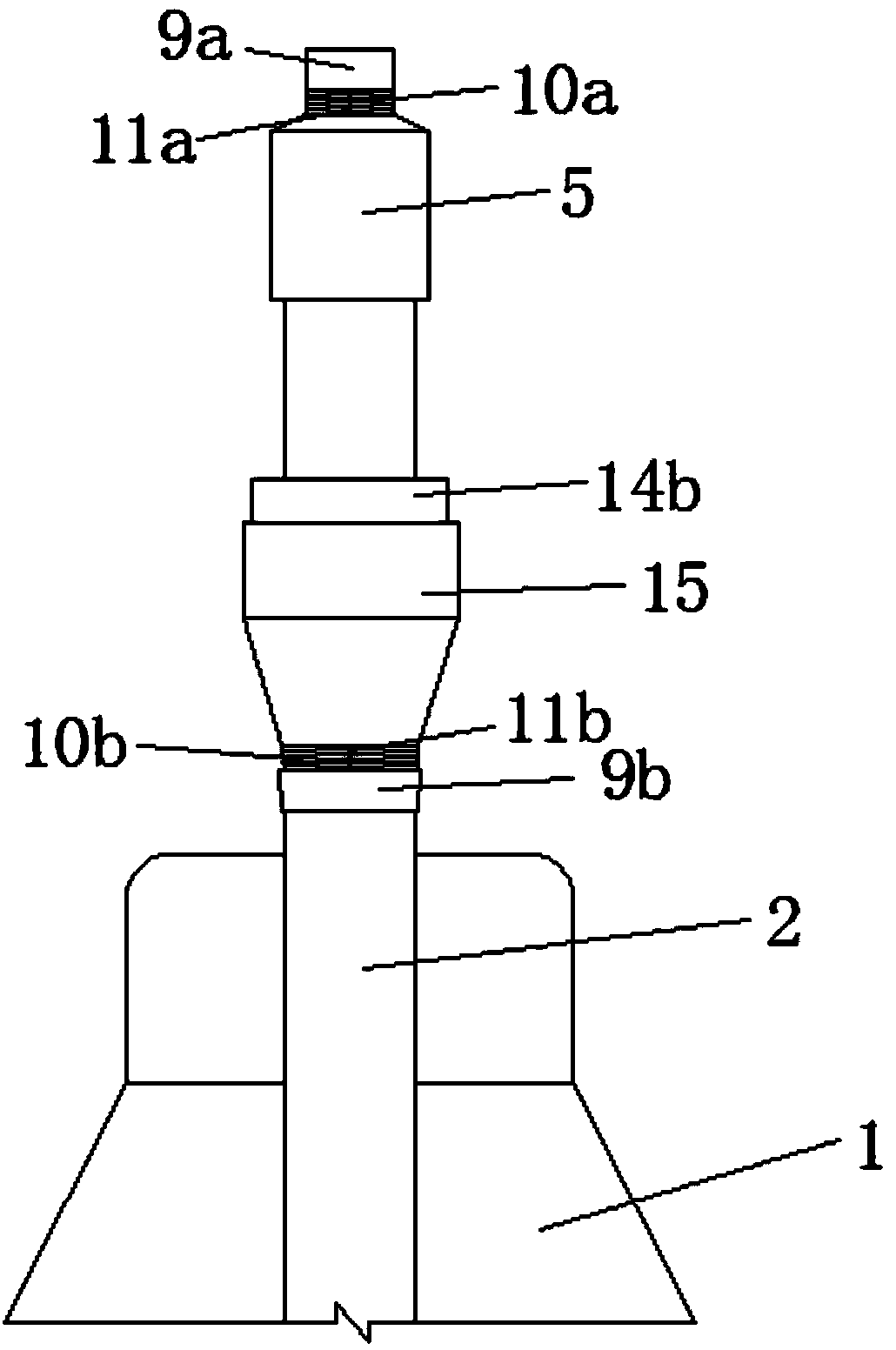

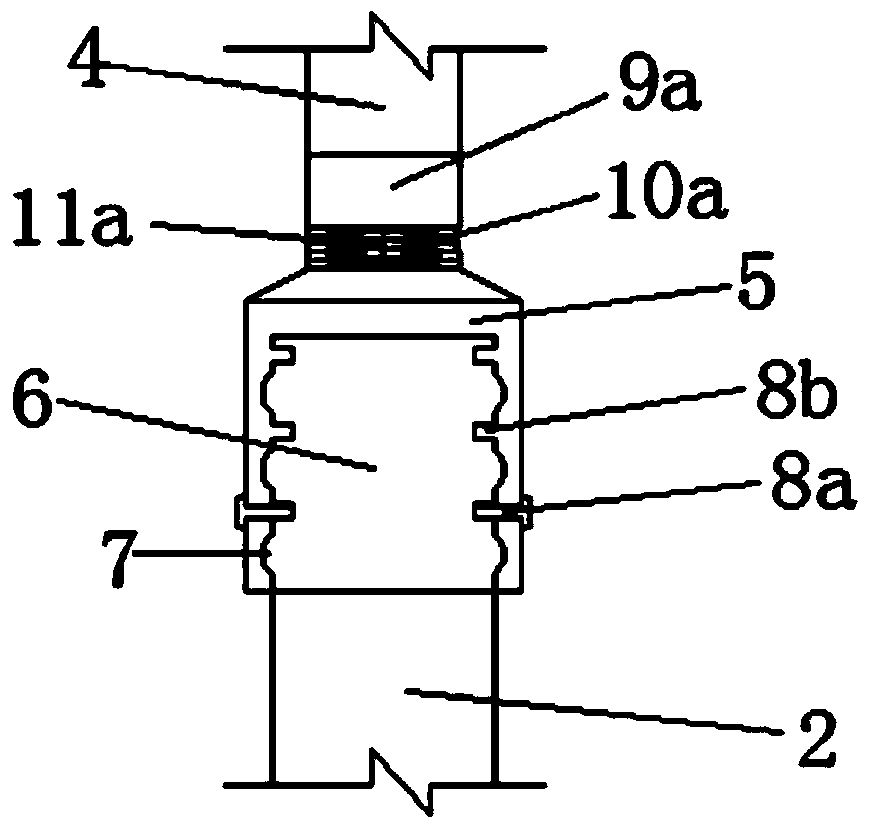

[0024] see figure 1 , figure 2 , image 3 , Figure 4 As shown, the grinding head retractable steel bridge test straight grinder of the present invention includes a straight grinder 1, a rotating mandrel 2, a coarse sand grinding head 3, a fine sand grinding head 12, a coarse sand grinding head expansion device 6, a fine sand grinding head Sand grinding head telescopic device 15.

[0025] Such as figure 1 and figure 2 As shown, a straight grinder with a retractable grinding head for steel bridge testing, including a straight grinder 1, a rotating mandrel 2, a coarse sand grinding head 3, a fine sand grinding head 12, a coarse sand grinding head telescopic device 6, a fine sand Grinding head retractable device 15. The coarse sand grinding head 3 is connected to the straight grinder 1 through the telescopic cap 5, and the fine sand grinder 12 is connected to the straight grinder 1 through the threaded interface 14a and the threaded joint 14b. The telescoping device 6 fo...

Embodiment 2

[0029] Such as figure 1 As shown in ~5, before grinding inside the steel box girder, turn the upper fixing nut 9a clockwise, insert the coarse sand grinding head 3 into the upper separate bayonet 10a, turn the upper fixing nut 9a counterclockwise, and fix the coarse sand Grinding head 3 can be polished. When it is necessary to grind a longer distance (the other side of the welding hole 19), loosen the screw 8a, slide the telescopic cap 5, and select a suitable screw hole 8b for fixing as required. After the preliminary grinding, install the fine sand grinding head 12, connect it with the rotating mandrel 2 through the threaded interface 14a and the threaded joint 14b, turn the lower fixed nut 9b counterclockwise, loosen the lower separate bayonet 10b, and the whole fine sand grinding The head 12 can slide on the rotating mandrel 2, and the lower fixed nut 9b is rotated clockwise, and the lower separated opening 10b is tightly fixed without relative sliding, and the other side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com