TiO2/C hybrid aerogel modified polyvinylidene fluoride membrane and preparation method thereof

A technology of polyvinylidene fluoride membrane and polyvinylidene fluoride, applied in the field of membrane separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

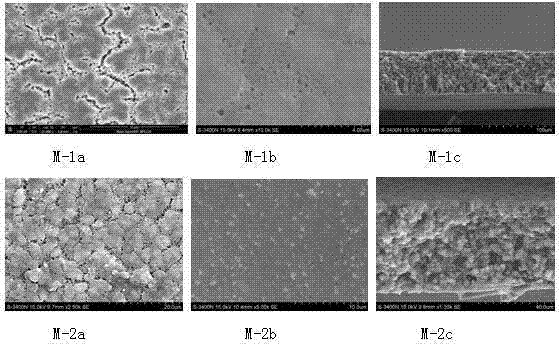

Embodiment 1

[0035] Weigh 32g PVDF, 163g N,N-dimethylacetamide, 4g polyvinylpyrrolidone and 1gTiO 2 / C hybrid airgel was placed in a three-necked round-bottomed flask, mechanically stirred in a water bath at 60°C for 12h until the solid powder was completely dissolved; then the casting solution was left standing at 60°C for defoaming for 12h to prepare for scraping, and finally Use a glass rod to scrape the casting solution on the glass plate to form a film (requirement: the glass plate must be absolutely dry, clean, and free from impurities); expose the glass plate to the air for 20 seconds and then immerse it in a coagulation bath at 20°C (50~ 60% ethanol aqueous solution) into a film by immersion precipitation phase inversion. Soak the prepared film in distilled water for one week and then dry it in an oven at 60°C to obtain the film, which can be cut according to the required size before use.

Embodiment 2

[0037] Weigh 32g PVDF, 162g N,N-dimethylacetamide, 4g polyvinylpyrrolidone and 2gTiO 2 / C hybrid airgel was placed in a three-necked round-bottomed flask, mechanically stirred in a water bath at 60°C for 12h until the solid powder was completely dissolved; then the casting solution was left standing at 60°C for defoaming for 12h to prepare for scraping, and finally Use a glass rod to scrape the casting solution on the glass plate to form a film (requirement: the glass plate must be absolutely dry, clean, and free from impurities); expose the glass plate to the air for 20 seconds and then immerse it in a coagulation bath at 20°C (50~ 60% ethanol aqueous solution) into a film by immersion precipitation phase inversion. Soak the prepared film in distilled water for one week and then dry it in an oven at 60°C to obtain the film, which can be cut according to the required size before use.

Embodiment 3

[0039] Weigh 32g PVDF, 161g N,N-dimethylacetamide, 4g polyvinylpyrrolidone and 3gTiO 2 / C hybrid airgel was placed in a three-necked round-bottomed flask, mechanically stirred in a water bath at 60°C for 12h until the solid powder was completely dissolved; then the casting solution was left standing at 60°C for defoaming for 12h to prepare for scraping, and finally Use a glass rod to scrape the casting solution on the glass plate to form a film (requirement: the glass plate must be absolutely dry, clean, and free from impurities); expose the glass plate to the air for 20 seconds and then immerse it in a coagulation bath at 20°C (50~ 60% ethanol aqueous solution) into a film by immersion precipitation phase inversion. Soak the prepared film in distilled water for one week and then dry it in an oven at 60°C to obtain the film, which can be cut according to the required size before use.

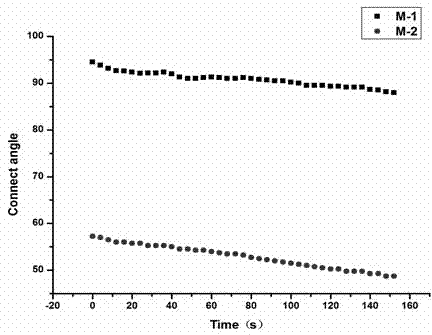

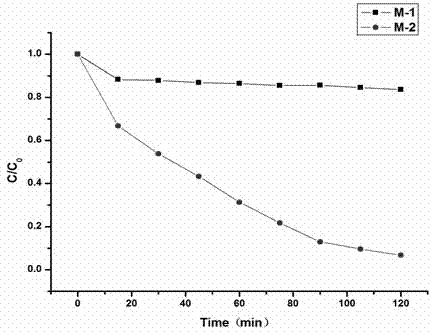

[0040] For the prepared TiO 2 / C modified PVDF ultrafiltration membrane performance test and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com