Foam distillation purification method

A foam and foam separation technology, applied in the field of separation and purification, can solve problems such as purification of untargeted components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Example 1, for purifying fungal hydrophobin HGFⅠ from fermentation supernatant

[0071] 1 Estimate the content of HGFⅠ and miscellaneous proteins in the fermentation supernatant;

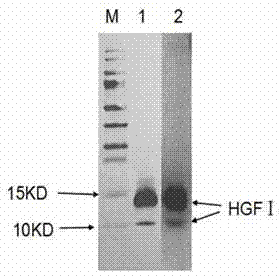

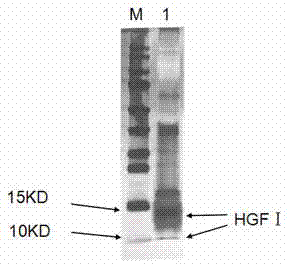

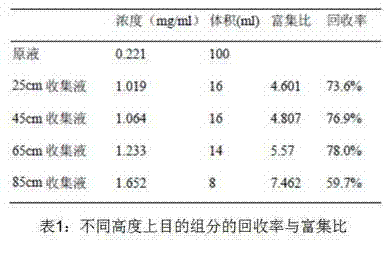

[0072] The fermentation supernatant mainly contains ions and other small molecular substances and proteins. Since the ultrafiltration method has advantages in removing ions, we do not regard ions and other small molecular substances as impurities in the foam separation process, but only miscellaneous proteins. As impurities, that is, HGFⅠ is the target component mentioned above, and miscellaneous protein is the target impurity. By performing sds-page electrophoresis on the fermentation supernatant as figure 2(M: marker, 1: HGFⅠ fermentation broth), and grayscale analysis of the gel, we got the result that HGFⅠ accounted for about 60% of the total grayscale of the swimming lane, and miscellaneous proteins accounted for about 40% of the total grayscale of the swimming lane. Through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com