Waterproof microphone

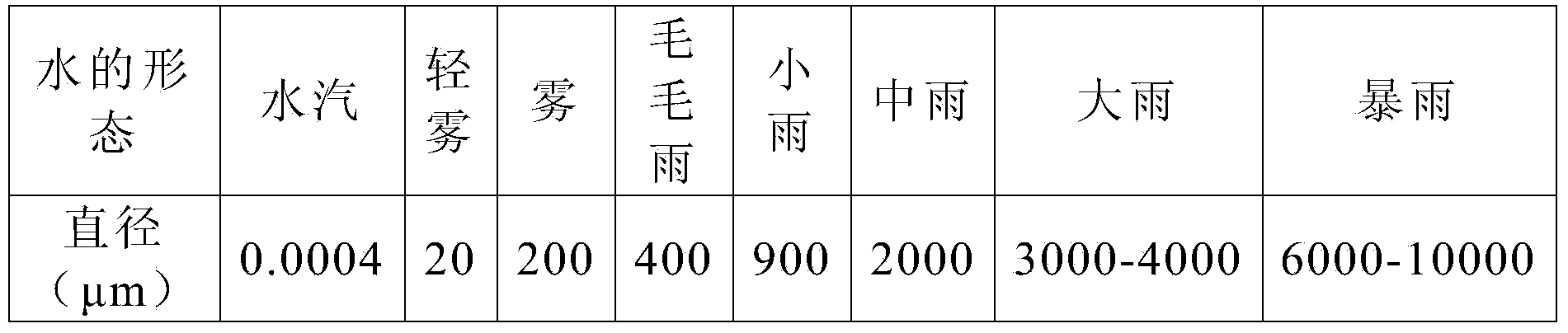

A microphone and waterproof technology, which is applied in the field of microphones, can solve the problems of microphone damage and short service life of the microphone, and achieve the effects of long life, wide application range and enhanced waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

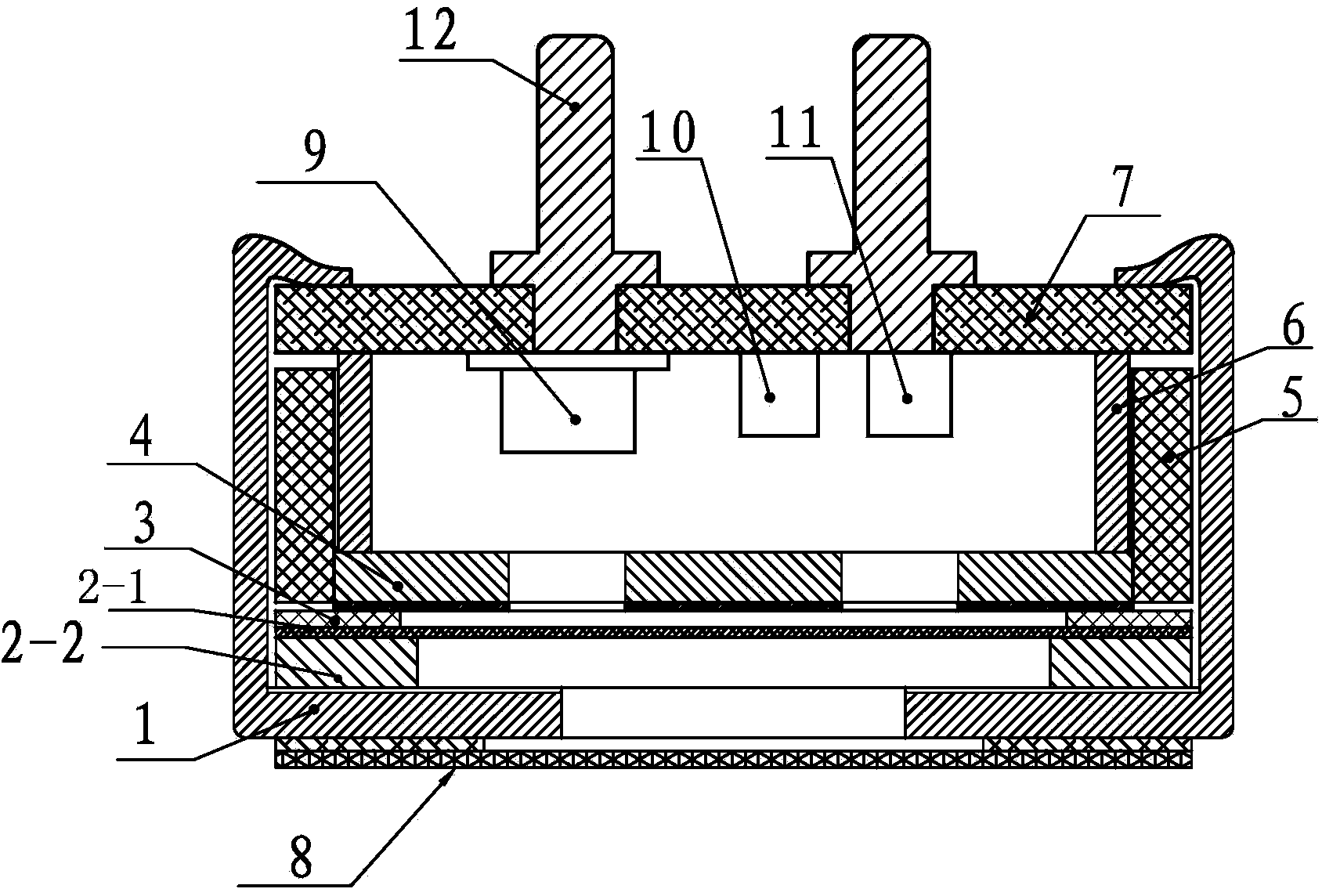

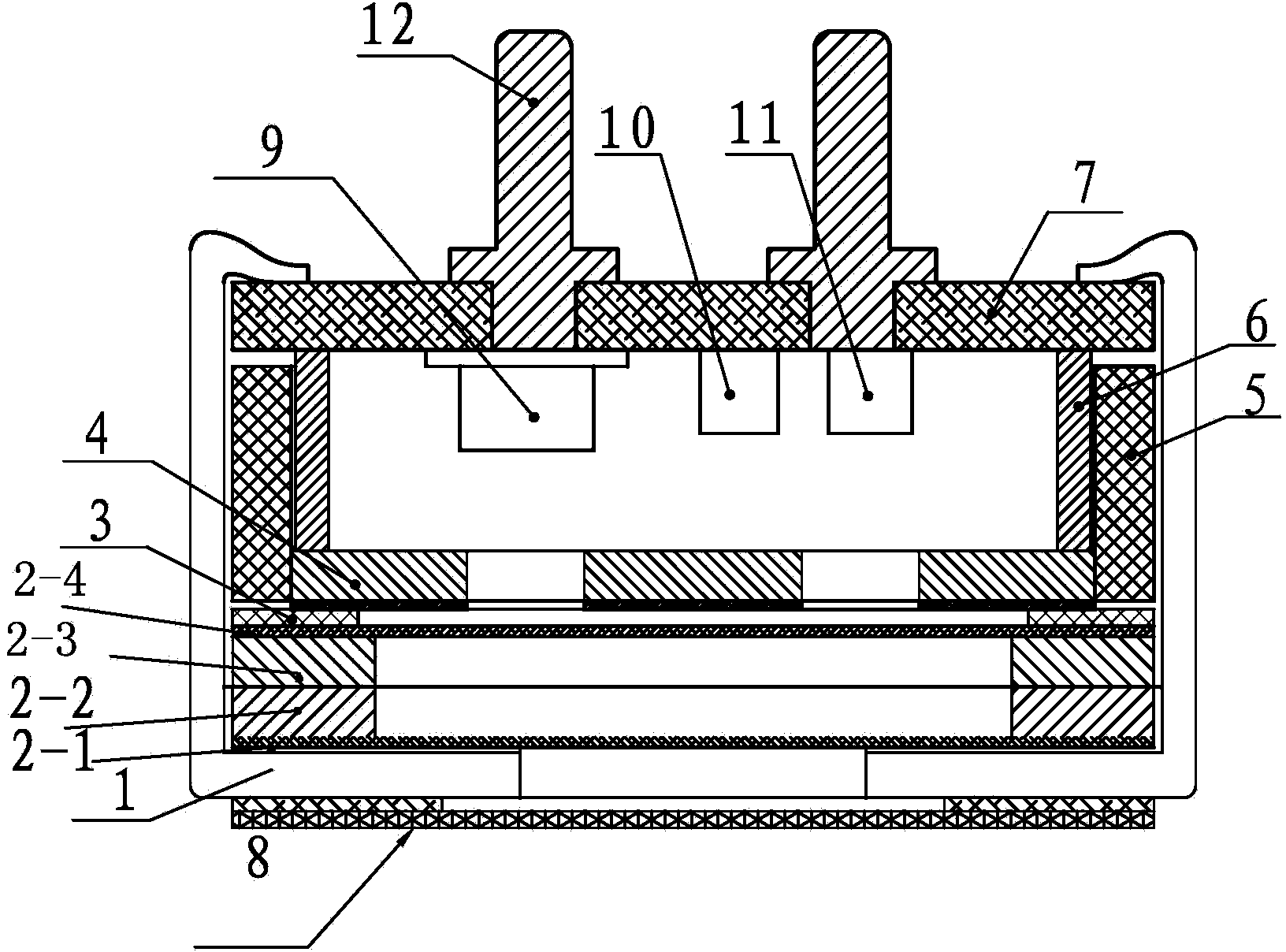

Image

Examples

Embodiment 1

[0043] Prepare a 20% polyamino modified resin aqueous solution for use. The acrylic fabric matrix with a pore size of 200 mesh is completely immersed in the prepared aqueous solution of polyamino modified resin, and then padding is carried out 5 times with a rolling mill. The rolling pressure is controlled to 0.1MPa and the rolling margin is 50%, so that the film forming agent is coated Covered on the fabric base. Then bake in a toaster at a baking temperature of 200°C for 10 minutes. Afterwards, the fabric substrate was completely immersed in the ethyl acetate solution of vinyl / amino co-modified silicone oil with a concentration of 5%, and then padding was carried out 4 times with a rolling mill. The rolling pressure was also controlled at 0.1 MPa, and the rolling margin was 50. %, the waterproofing agent is coated on the fabric substrate. Finally, the fabric was baked in a baking machine at a baking temperature of 140°C for 20 minutes, and dried to obtain a waterproof membr...

Embodiment 2

[0045] Prepare a 30% concentration of methyl acrylate copolymer aqueous solution for use. The polyester fabric matrix with a pore size of 300 mesh is completely immersed in the prepared methyl acrylate copolymer aqueous solution, and then padding is carried out 3 times with a rolling mill. The rolling pressure is controlled to 0.2MPa and the rolling margin is 65%, so that the film forming agent is coated Covered on the fabric base. Then it was baked in a toaster at a baking temperature of 210°C for 8 minutes. After that, the fabric substrate is completely immersed in the ethyl acetate solution of 10% vinyl / amino co-modified silicone oil, and then padding is carried out 3 times. The rolling pressure is also controlled at 0.2MPa, and the rolling margin is 65%. The waterproofing agent is coated on the fabric substrate. Finally, it was baked in a baking machine at a baking temperature of 160°C for 18 minutes and dried to obtain a waterproof membrane.

Embodiment 3

[0047] Prepare a 35% concentration ethylene / vinyl acetate polymerization wax aqueous solution for use. The nylon fabric substrate with a pore size of 350 mesh is completely immersed in the prepared ethylene / vinyl acetate polymerization wax aqueous solution, and then padding is carried out twice by a rolling mill. The rolling pressure is controlled to 0.3MPa and the rolling margin is 70% to form a film. The agent is coated on the fabric substrate. Then bake in a toaster at a baking temperature of 220°C for 7 minutes. After that, the fabric substrate is completely immersed in the ethyl acetate solution of 15% vinyl / amino co-modified silicone oil, and then padding for 3 times. The pressure of the rolling mill is also controlled at 0.3MPa, and the rolling margin is 70%. The waterproofing agent is coated on the fabric substrate. Finally, it was baked in a baking machine at a baking temperature of 170°C for 15 minutes and dried to obtain a waterproof membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com