Partial tail gas circulation fluid bed drying method and equipment

A technology of fluidized bed drying and fluidized bed drying machine, which is applied in the direction of drying solid materials, drying gas arrangement, lighting and heating equipment, etc., and can solve the problems of low heat energy utilization rate, poor heat transfer effect, difficult continuous operation, etc. Reach the effect of reducing the temperature of exhaust gas, avoiding material denaturation and reducing the total amount of exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1 The method for part tail gas circulating fluidized bed drying of the present invention comprises the following steps:

[0054] 1) Material drying:

[0055] The wet material is continuously fed into the fluidized bed dryer by the screw feeder, dispersed, heated, fluidized and preliminarily dried in the first chamber, and then enters each drying chamber to continue fluidized, heated and dried, and the material is dried to a certain When the bed temperature reaches 125-135°C, it enters the cooling chamber and is cooled by the cooling gas. After the bed temperature reaches 45-55°C, the material is discharged into the block separator by the screw discharger for block separation. The qualified products are separated by the gas for separation. Transported to the bag filter for packaging and storage after separation;

[0056] The lumps separated by the lump separator are discharged from the first star discharger for reprocessing;

[0057] The dust entrained by th...

Embodiment 2

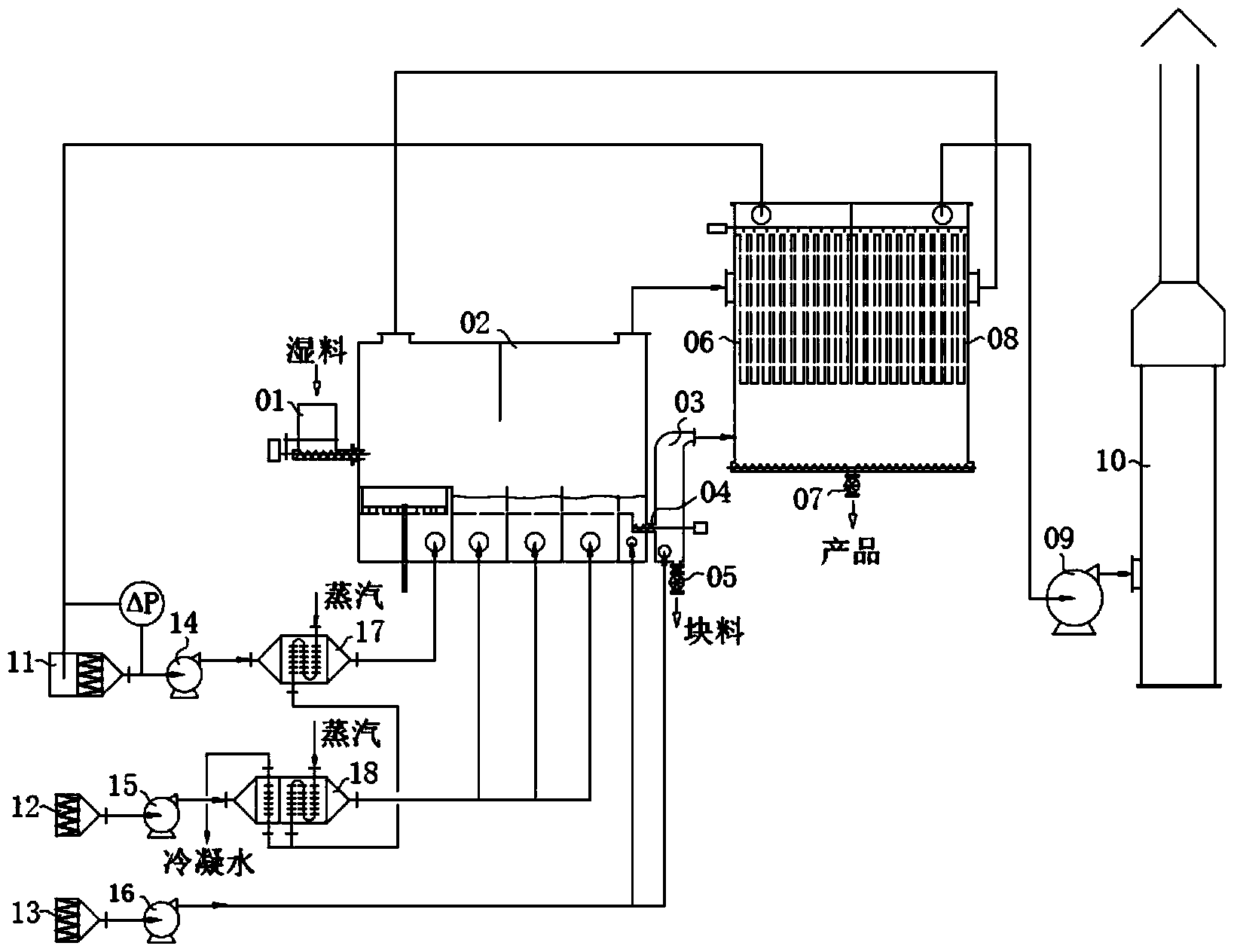

[0066] Example 2 The equipment constructed according to the method for drying part of the tail gas circulating fluidized bed according to the present invention includes a fluidized bed dryer body 02, a screw feeder 01, a first heating device, a second heating device, a cooling device, Dust removal device, the fluidized bed dryer body 02 includes an upper bed body 31, a lower bed body 37, and a distribution plate 36, and the distribution plate 36 is installed in the cavity formed by the upper bed body 31 and the lower bed body 37. Tongue-shaped punching, the opening is towards the outlet of the fluidized bed dryer; the top plate of the upper bed body 31 is provided with a first exhaust port 30 and a second exhaust port 28 communicating with the inner cavity, and the side wall is provided with an outlet connected to the inner cavity. Connected wet material inlet 34 and material outlet 22; the lower bed body 37 is provided with a first hot air inlet, a second hot air inlet and a c...

Embodiment 3

[0078] Embodiment 3 (1) with figure 1 Partial tail gas circulating fluidized bed drying process flow chart (external bagging process)

[0079] Material flow: The wet material is continuously fed into the fluidized bed dryer 02 by the screw feeder 01, dispersed by the rake 35 in the first room, fluidized by hot air, and preliminarily dried, and then enters each drying room in sequence to continue fluidization, heating, Drying, the material is dried to a certain extent, the bed temperature reaches 125-135°C and enters the cooling chamber 23 to be cooled by the cooling gas, the bed temperature reaches 45-55°C, the material is discharged into the block separator 03 by the screw discharger 04 for block Materials are separated, and the qualified products are transported to the first bag filter 06 by the gas used for separation and packaged and stored by the second star discharger 07.

[0080] The lumps separated by the lump separator 03 are discharged from the first star discharger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com