Lubrication and cooling system of low-temperature thermal power generation expander

A technology of cooling system and expander, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as complex structure, leakage of power generation medium, and many operating problems, so as to simplify the lubrication and cooling system, eliminate economic losses, and save energy. The effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The lubricating and cooling system of the low-temperature thermal power generation expander of the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

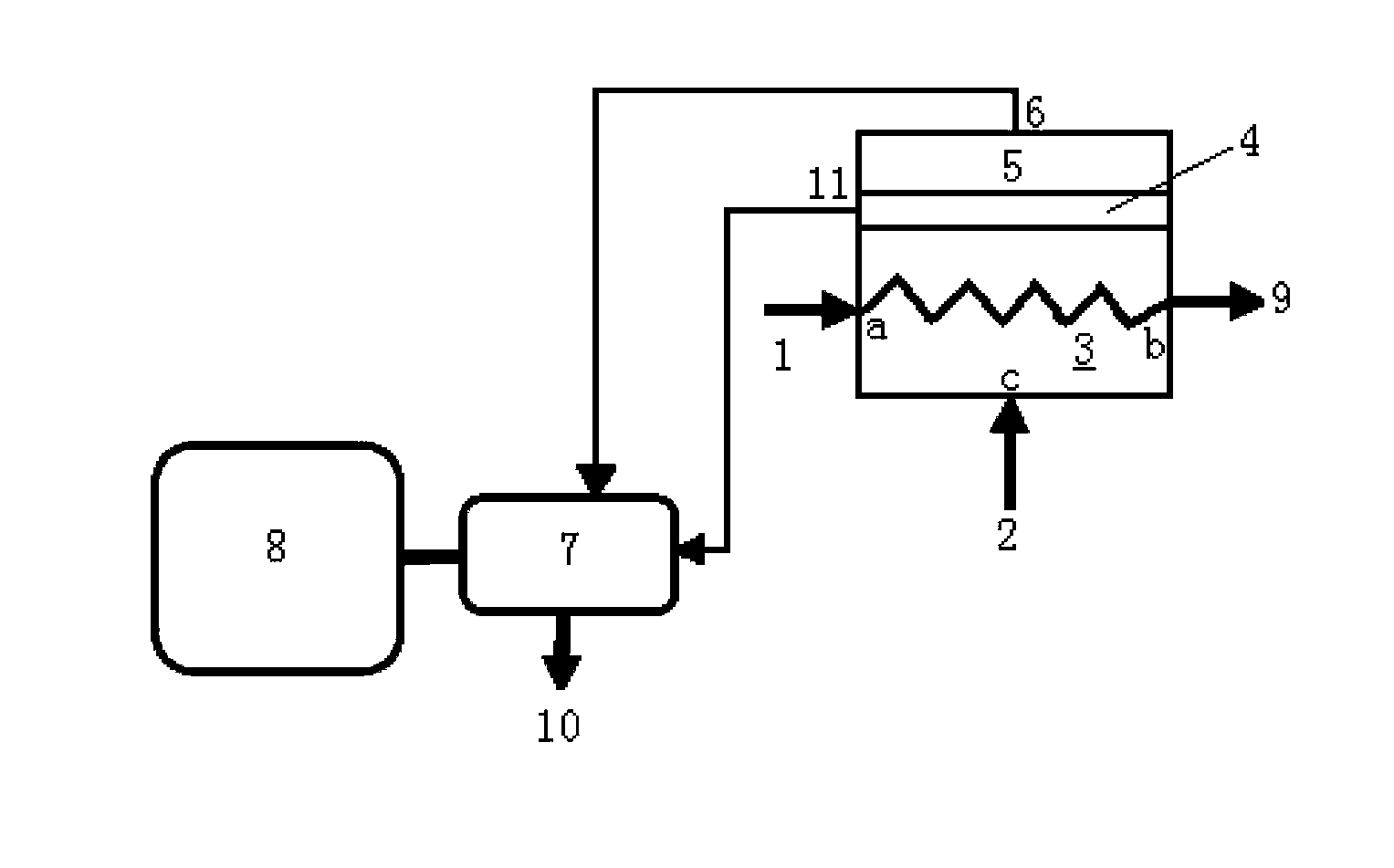

[0026] The lubrication and cooling system of the low-temperature thermal power generation expander of the present invention includes a synchronous generator 8 and a twin-screw expander 7 connected to the synchronous generator 8 for driving the synchronous generator 8, and is also provided with a flooded evaporator 3 , wherein, the heat source passage inlet a of the flooded evaporator 3 is connected to the low-temperature heat source 1 through a pipeline, the heat source passage outlet b of the flooded evaporator 3 is connected to the low-temperature heat source return pipe 9, and the flooded evaporator 3 The inlet c of the oil-mixed power generation medium is connected to the oil-mixed power generation medium 2 through a medium pipeline, and the outlet 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com