Setting machine

A technology of setting machine and frame, which is applied in the direction of heating/cooling fabrics, textiles and papermaking, and fabric surface trimming, etc., which can solve the problems of clothes being scalded and continuous production, and achieve a good setting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below in conjunction with accompanying drawing:

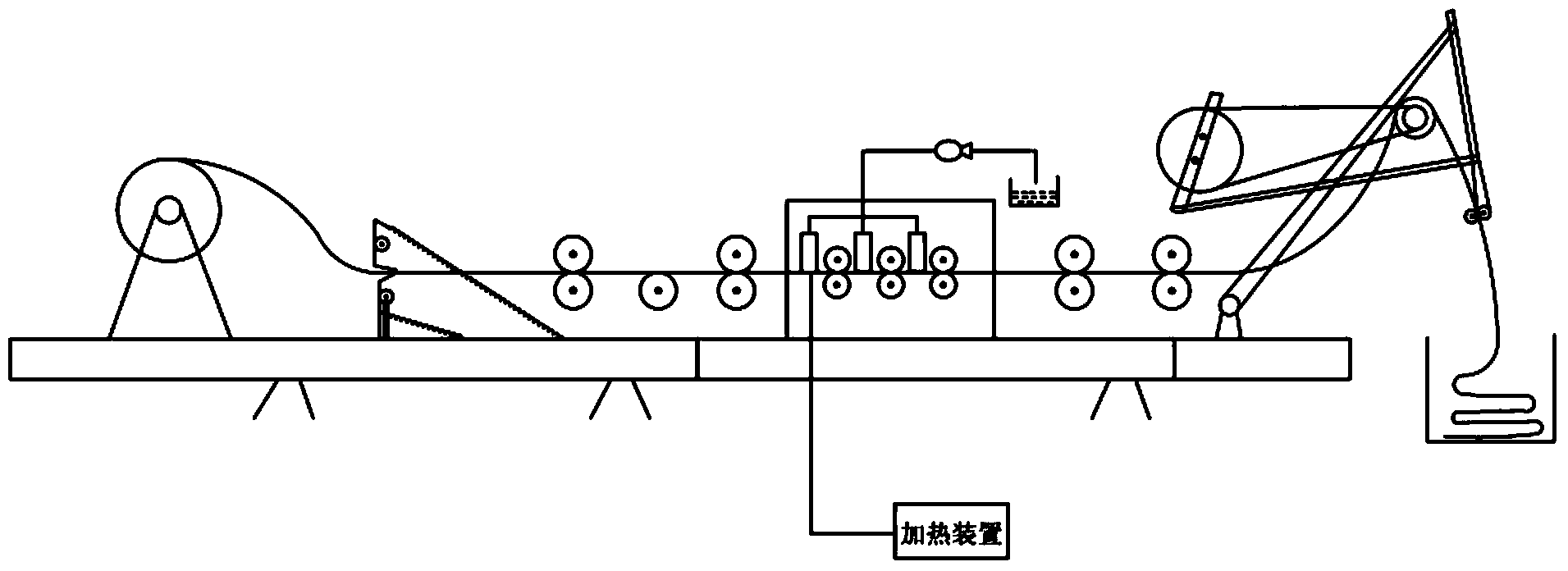

[0009] Such as figure 1 As shown, this sizing machine includes a frame 1, and one side of the frame 1 is provided with a reel A2 for rolling the fabric 3, and the fabric 3 passes through the platen group 4, the first roller group 7 and the second roller group. The roller group 8 enters the shaping box 25, wherein the pressing plate group 4 is a folded plate structure that can rotate around the rotating shaft 5, one side of the folded plate is used to compress the fabric 3, and the other side is fixedly connected with the frame 1 by the spring 6; The elastic force makes the folded plate be pressed tightly on the two sides of the fabric 3, so that it can be flattened and pretreated before entering the calibrating box. A group of water spray pipes 9 and heating press roller sets 12 arranged at intervals are arranged in the said sizing box 25, wherein the water spray pipes 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com