Jutecell fiber Raschel blanket and technology for manufacturing Jutecell fiber Raschel blanket

A raschel blanket, production process technology, applied in the direction of fiber type, fiber treatment, plant fiber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of production technology of hemp cell fiber double-layer Raschel blanket, comprises the following steps:

[0028] 1. Production of double layer raschel blanket products on double needle bed warp knitting machine

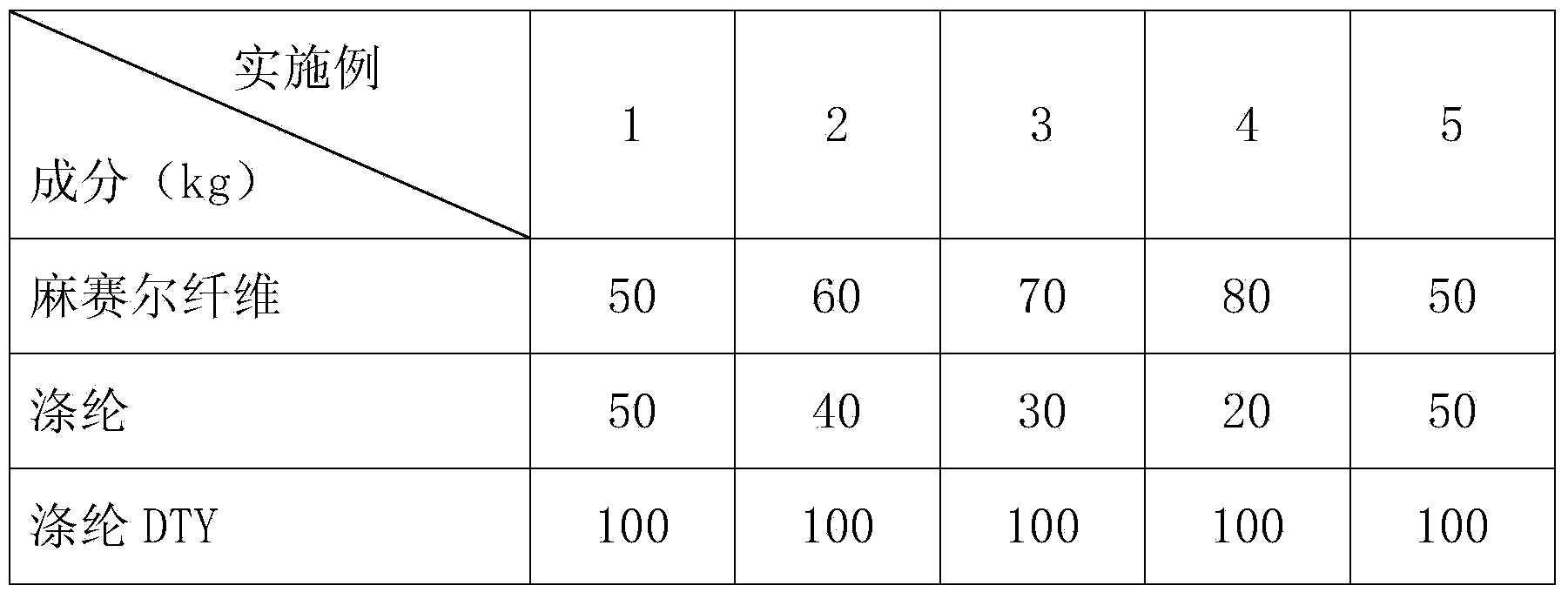

[0029] (1) Select yarn

[0030] Choose to use mosaic blended yarn with a specification of 17s as the plush yarn, and use 150D / 72F polyester DTY as the ground yarn.

[0031] (2) Select fabric weave

[0032] The E2291A double-needle bed warp knitting machine is used for knitting. The No. 1 and No. 6 bars knit 3 needle weft inserts on the front and rear needle beds respectively. The No. 2 and No. 5 bars knit chains on the front and rear needle beds respectively. Knit plush on the front and rear needle beds.

[0033] (3) Weaving

[0034] E2291A double-needle bed warp knitting machine is adopted, with 6 bars, gauge number 16, and the distance between the front and rear needle beds of the Maser fiber Raschel blanket is 10mm. When knitting, make sure to a...

Embodiment 2

[0056] A kind of production technology of hemp cell fiber double-layer Raschel blanket, comprises the following steps:

[0057] 1. Production of double-layer Raschel blanket products on a double-needle bed warp knitting machine

[0058] (1) Select yarn

[0059] Choose to use the mosaic blended yarn with a specification of 18s as the plush yarn, and use 150D / 72F polyester DTY as the ground yarn.

[0060] (2) Select fabric weave

[0061] The E2291A double-needle bed warp knitting machine is used for knitting. The No. 1 and No. 6 bars knit 3 needle weft inserts on the front and rear needle beds respectively. The No. 2 and No. 5 bars knit chains on the front and rear needle beds respectively. Knit plush on the front and rear needle beds.

[0062] (3) Weaving

[0063] E2291A double-needle bed warp knitting machine is adopted, with 6 bars, gauge number 18, and the distance between the front and rear needle beds of the Maser fiber Raschel blanket is 10mm. When knitting, make sur...

Embodiment 3

[0085] A kind of production technology of hemp cell fiber double-layer Raschel blanket, comprises the following steps:

[0086] 1. Production of double-layer Raschel blanket products on a double-needle bed warp knitting machine

[0087] (1) Select yarn

[0088] Choose to use mosaic blended yarn with a specification of 19s as the plush yarn, and use 75D / 36F polyester DTY as the ground yarn.

[0089] (2) Select fabric weave

[0090] The E2291A double-needle bed warp knitting machine is used for knitting. The No. 1 and No. 6 bars knit 3 needle weft inserts on the front and rear needle beds respectively. The No. 2 and No. 5 bars knit chains on the front and rear needle beds respectively. Knit plush on the front and rear needle beds.

[0091] (3) Weaving

[0092] Adopt E2291A type double-needle bed warp knitting machine, 6 bars, the gauge is 20, and the distance between the front and rear needle beds of the Maser fiber Raschel blanket is 10mm. When knitting, make sure to adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com