A method to improve the signal-to-noise ratio of high-energy short-pulse laser

A short-pulse laser and signal-to-noise ratio technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of high-energy short-pulse laser signal-to-noise ratio inefficiency, difficult debugging, etc., to achieve reduced adjustment difficulty, low cost, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

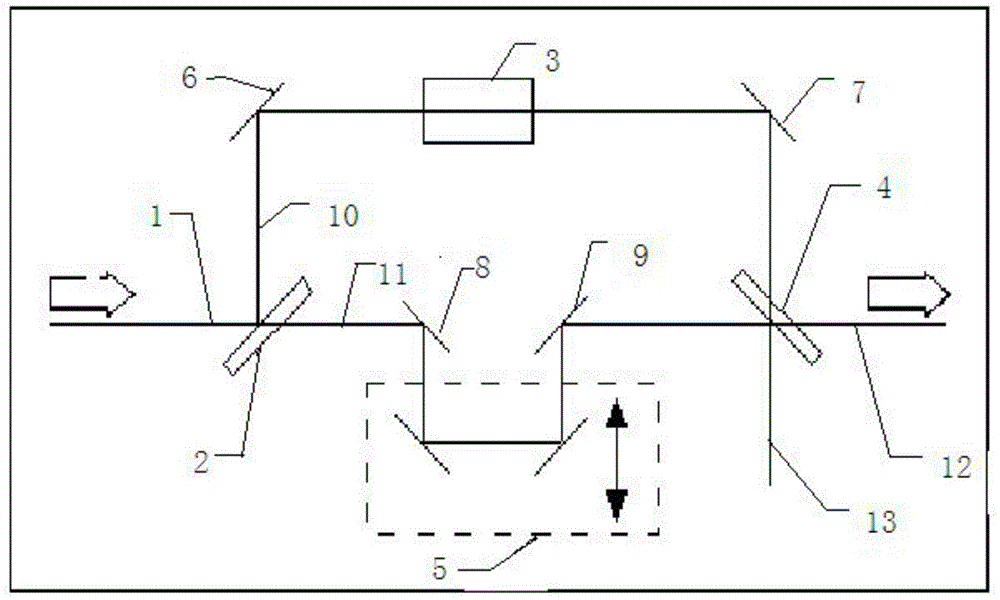

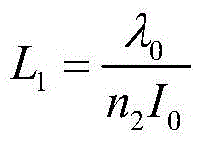

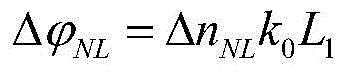

[0035] The central wavelength λ of the main peak of the high-energy short-pulse laser pulse in this embodiment 0 800nm, energy 6mJ, beam aperture 10mm, pulse width 50fs; the material of the nonlinear optical medium is K9 glass, and the nonlinear refractive index coefficient is n 2 =3.75×10 - 16 cm 2 / W. Calculate the peak power density I of the pulse main peak 0 =153GW / cm 2 by the formula Determine the thickness of the K9 glass to be 14mm.

[0036] like figure 1 Shown is a schematic diagram of the optical path structure of a method for improving the signal-to-noise ratio of high-energy short pulses in the present invention. As shown in the figure, the high-energy short-pulse laser 1 first shoots into the half-transparent half-reflective film of the first half-mirror 2, and then It is divided into two beams, including the first sub-beam 10 as a reflected beam, the second sub-beam 11 as a transmitted beam, and the second sub-beam 11 is emitted through the high-transmitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com