Laser optical path used for target focal spot shaping and beam smoothing

A focal spot and beam technology, applied in the field of optical path system, can solve the problems of poor versatility, high cost, and large total thickness of the beam, and achieve the effects of reducing the risk of damage, low cost, and reducing the total thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

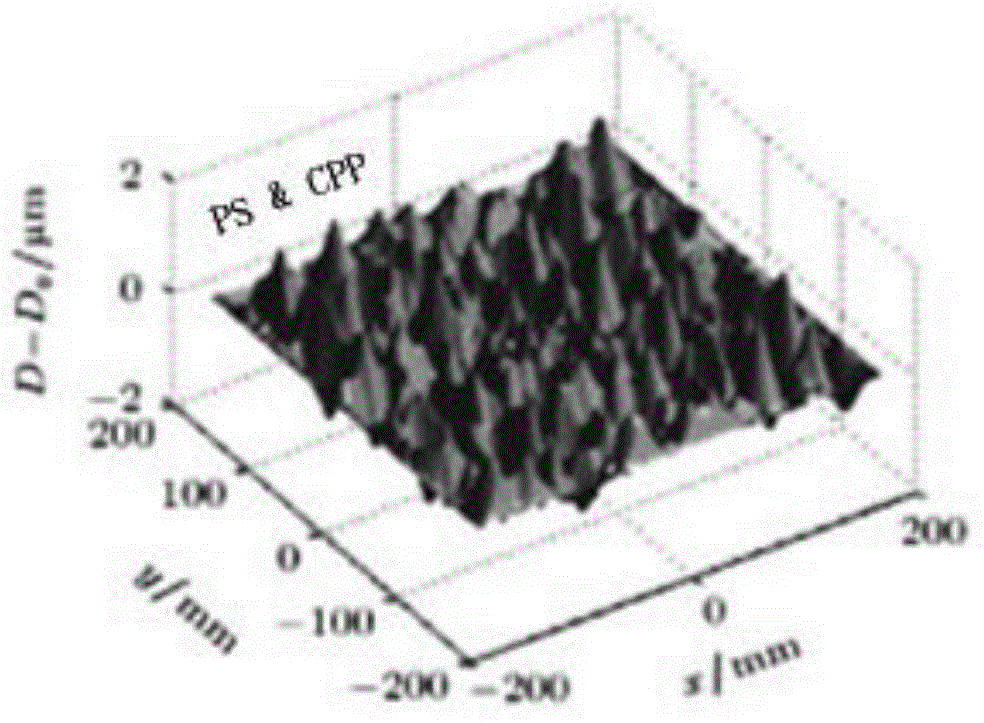

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description. For the sake of simplicity, CPP is used to represent the common continuous phase plate, CPP and PS are used to represent the combination of common continuous phase plate and polarization smooth crystal wedge, and PS&CPP is used to represent a kind of target focal spot shaping and beam uniformity of the present invention. Slide the phase plate in the laser beam path.

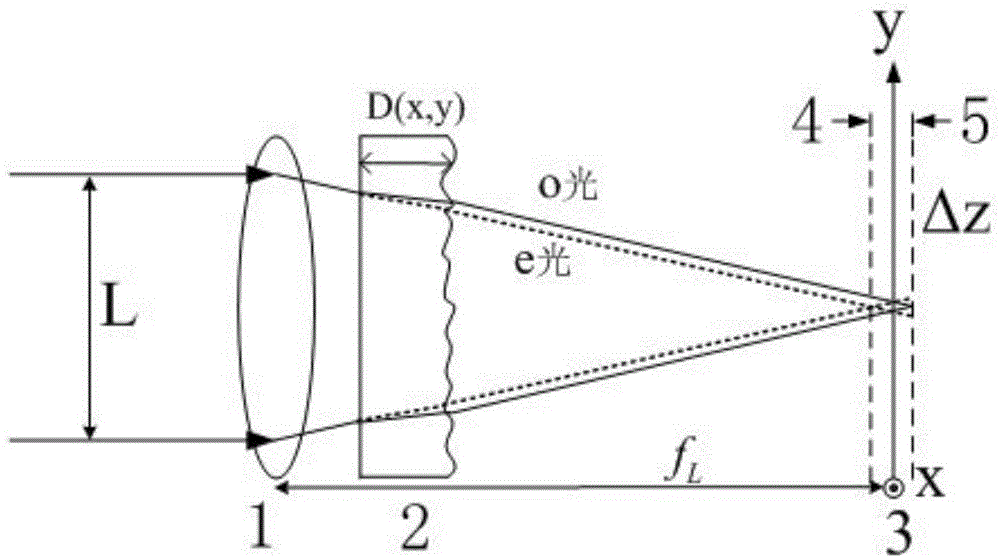

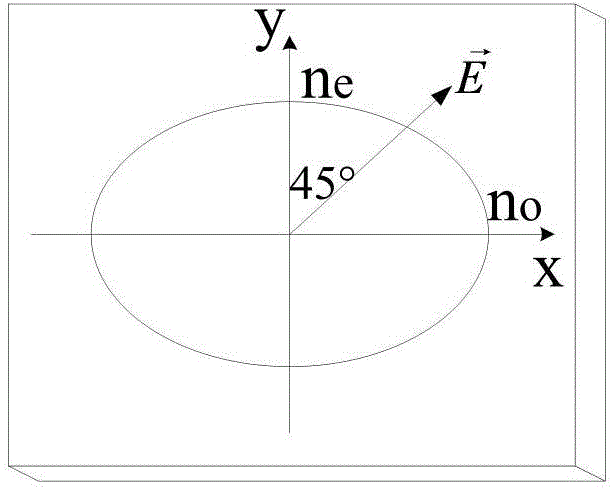

[0032] A laser optical path for target focal spot shaping and beam smoothing, such as figure 1 As shown, the incident light field L is perpendicular to the surface of the convex lens (1) and is focused by the convex lens (1) to form a focused beam. When the focused beam passes through PS&CPP (2), it is divided into ordinary light (o light) with equal intensity and extraordinary light (e light), and because there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com