Outdoor pipeline thermal insulation pipe shell

A technology of thermal insulation tube shell and outer pipeline, which is applied in the direction of pipeline protection, thermal insulation, and protection of pipeline through thermal insulation, etc., can solve the problems of unfavorable thermal insulation tube shell disassembly and reuse, affecting thermal insulation effect, heat loss, etc., to improve the reuse rate , to ensure the quality and speed of production, the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing of description, the present invention will be further described.

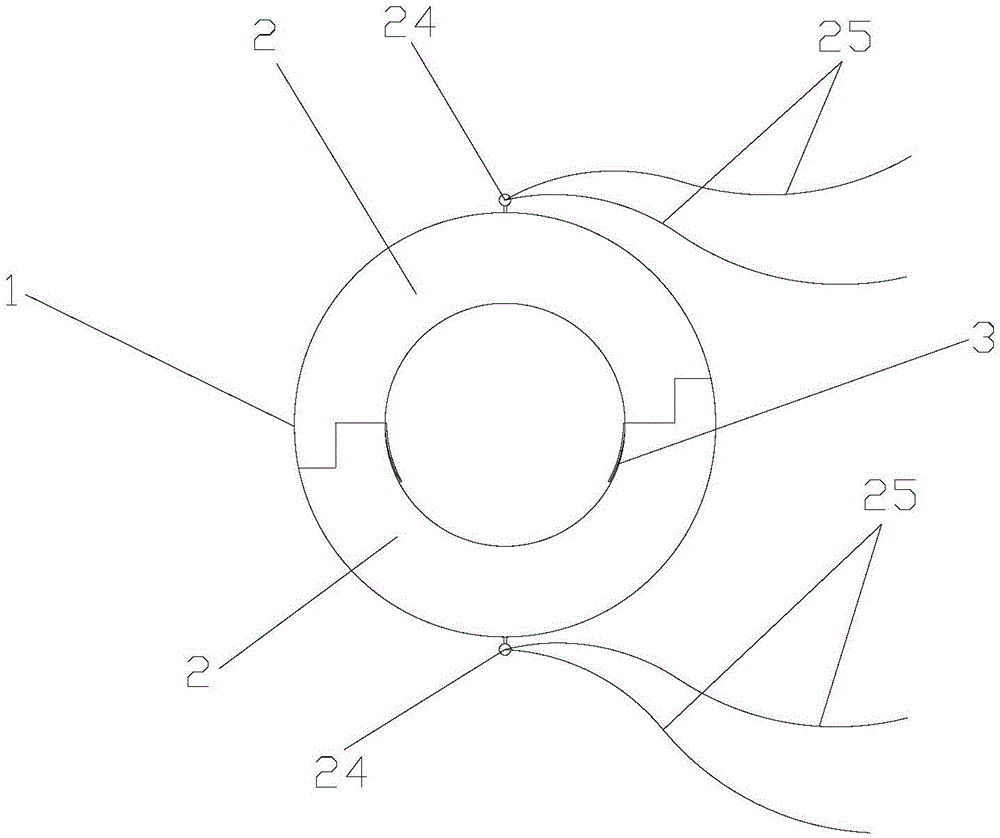

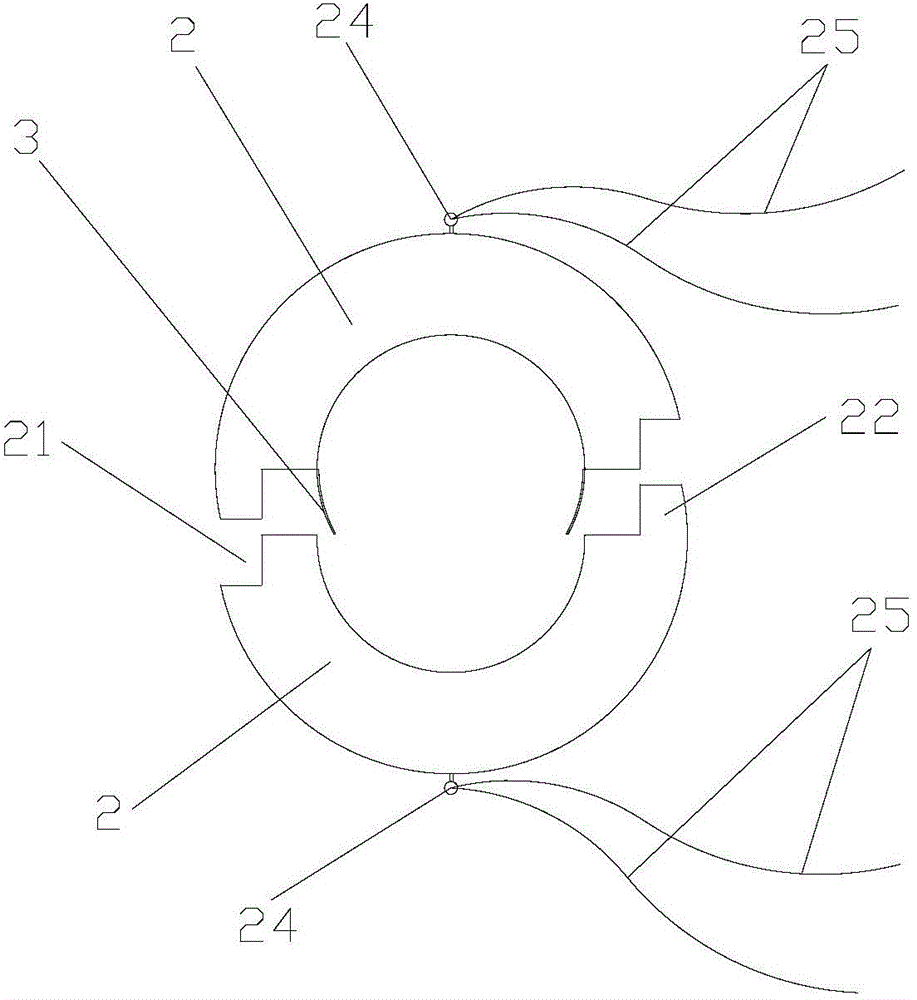

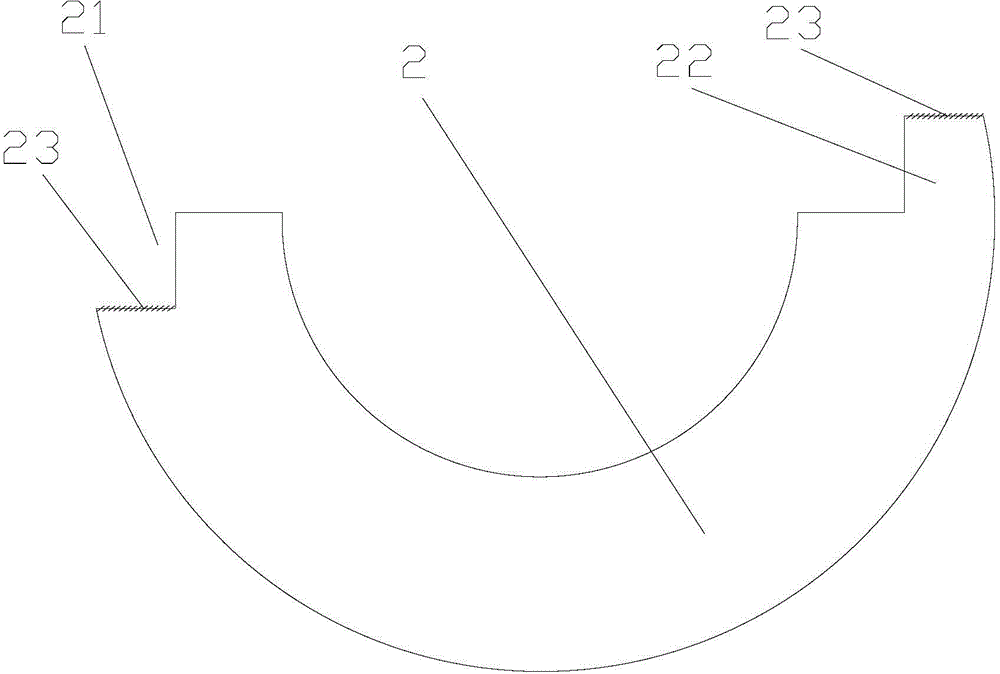

[0029] Such as figure 1 , figure 2 , image 3 ,and Figure 4 As shown in the figure, an outdoor pipe insulation shell includes a shell body 1 with a hollow cylindrical structure, and the shell body 1 includes two half shells 2, and the outer end of one end surface of the half shell 2 is provided with a concave Groove 21, the outer end of the other end surface of the half-shell 2 is provided with a convex step 22; the two ends of the inner surface of one of the half-shells 2 are provided with a sheet-like extension 3, the extension 3 The radian of the sheet fits the inner surface of the other half-shell; the extension part 3 is preferably made of soft thermal insulation material.

[0030] Wherein, the groove bottom plane of the groove 21 is provided with toothed lines 23 for filling glue; the step top plane of the convex step 22 is also provided with too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com