A kind of soil conditioner and preparation method thereof

A soil conditioner and soil technology, applied in soil conditioning materials, chemical instruments and methods, organic fertilizers, etc., can solve the problems of large site requirements, secondary pollution, and high costs, and achieve low cost, labor cost savings, and use methods. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

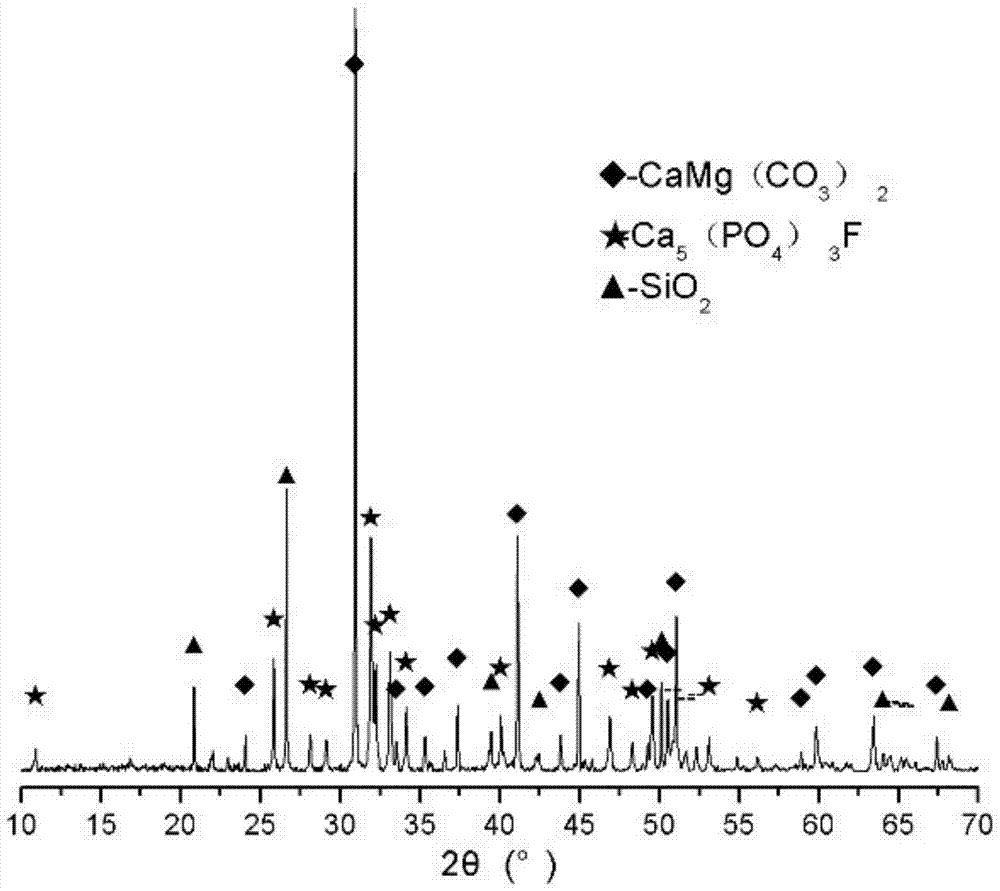

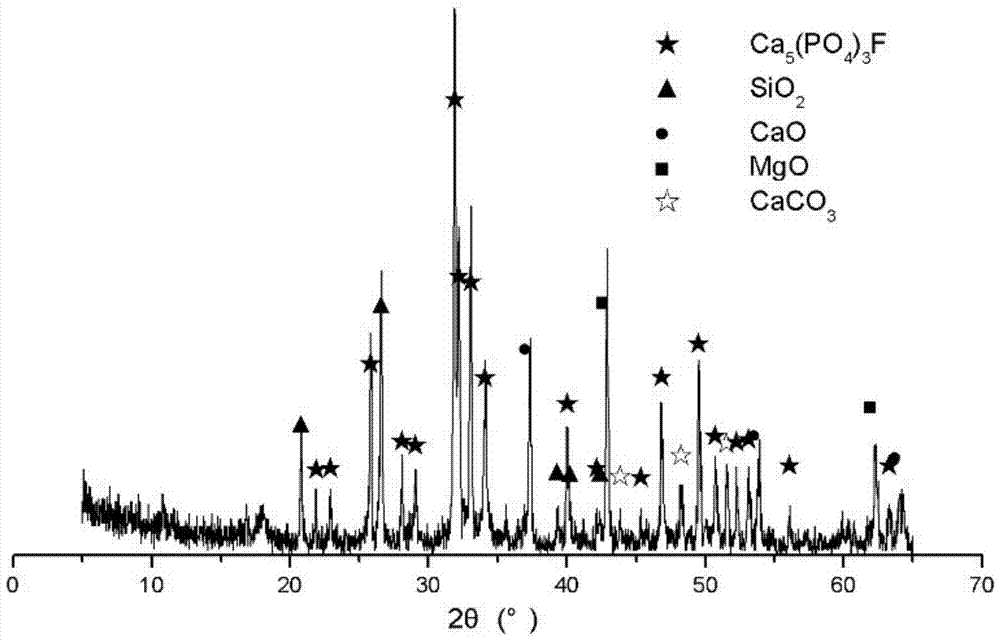

[0038] The reverse flotation phosphorus tailings were calcined at 900°C for 1.5 hours to obtain the calcined product. The XRD diffraction pattern of the reverse flotation phosphorus tailings is shown in the attached figure 1 . From attached figure 1 It can be seen from the above that the calcium magnesium carbonate and calcium fluorophosphate contained in the reverse flotation phosphorus tailings are substances that are not easy to react. At this time, the silicon dioxide contained in it is inactive silicon dioxide and cannot participate in the reaction; after a certain high temperature After calcining (the XRD diffractogram of the prepared active phosphorus tailings after calcining is referring to attached figure 2 ), the above substances are converted into calcium oxide, magnesium oxide, calcium carbonate, silicon dioxide and calcium fluorophosphate, etc., which can react with other substances to produce the required substances; , silicon oxide, etc., accelerate the react...

Embodiment 2-5

[0042] Through the introduction of Example 1, we know that the soil improver can be obtained by calcining and autoclaving the reverse flotation phosphorus tailings, but the soil improver prepared in this way is a poor particle, and it needs to wait for other Decompose under natural action, and just can play a role with soil fusion, onset time is long, and effect is not good, for this reason the present invention provides embodiment 2-5, improves soil conditioner by adding soil raw material wherein, active phosphorus tailings and soil The soil conditioner made after mixing can better integrate with poor soil, so that the soil conditioner can work faster.

[0043] In order to describe the gradual change, the following descriptions refer to reverse flotation phosphorus tailings unless otherwise specified.

[0044] Table 1

[0045] Numbering

Active phosphorus tailings (mass parts)

Soil (mass parts)

2

1

84

3

20

65

4

50

35

...

Embodiment 6-30

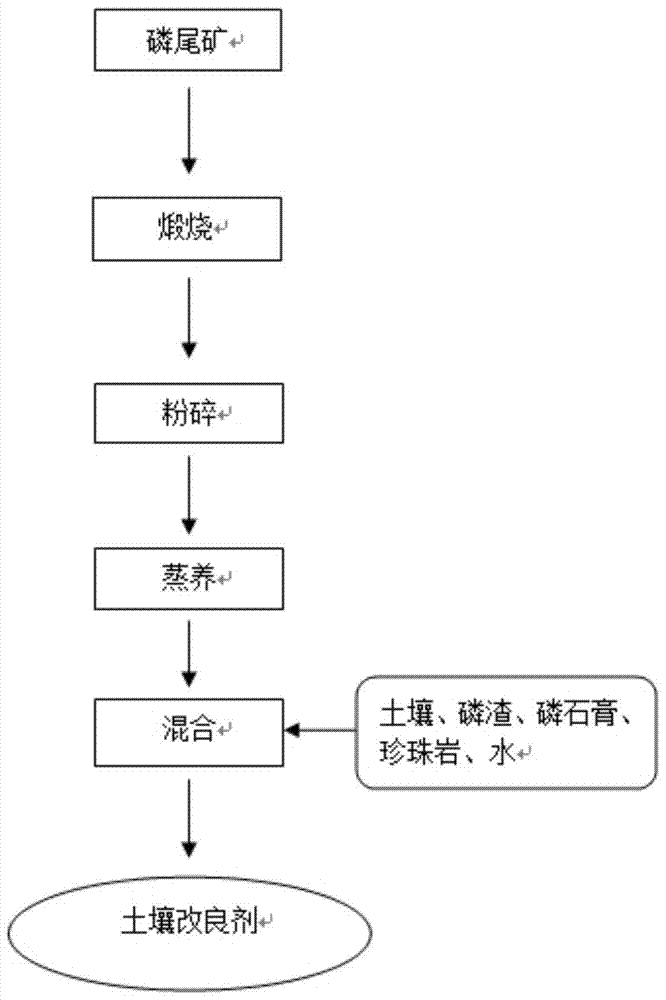

[0051] Embodiment 6-30 is a preferred embodiment of the present invention, and the process flow diagram of its preparation method can refer to the attached image 3 .

[0052] The mass ratio of soil to active phosphorus tailings in Examples 6-10 is 84:1, and the distribution ratio of each component is shown in Table 2.

[0053] Table 2

[0054]

[0055] In embodiment 6~10, the step of preparing above-mentioned soil conditioner is as follows:

[0056] The preparation method of the active phosphorus tailings is basically the same as the preparation method of the active phosphorus tailings provided in Examples 2-5. That is, reverse flotation phosphorus tailings are calcined at 800°C for 3 hours, and then crushed and screened. Particles of ≤50 mesh are taken for autoclave curing to obtain active phosphorus tailings. Autoclave curing is at 170-180°C, 0.8 Autoclave curing for 3 to 5 hours under the condition of ~1.0MPa; silica fume is added during autoclave curing, and the dos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com