Water-based antirust and antiseptic paint for metal and preparation method thereof

A metal anti-rust and anti-corrosion paint technology, applied in the direction of anti-corrosion coatings, polyester coatings, coatings, etc., can solve the problems of not reaching high-grade paints, poor gloss, and insufficient fullness of colored paint films, etc. Foaming rapidly, improving floating color phenomenon, assisting good film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

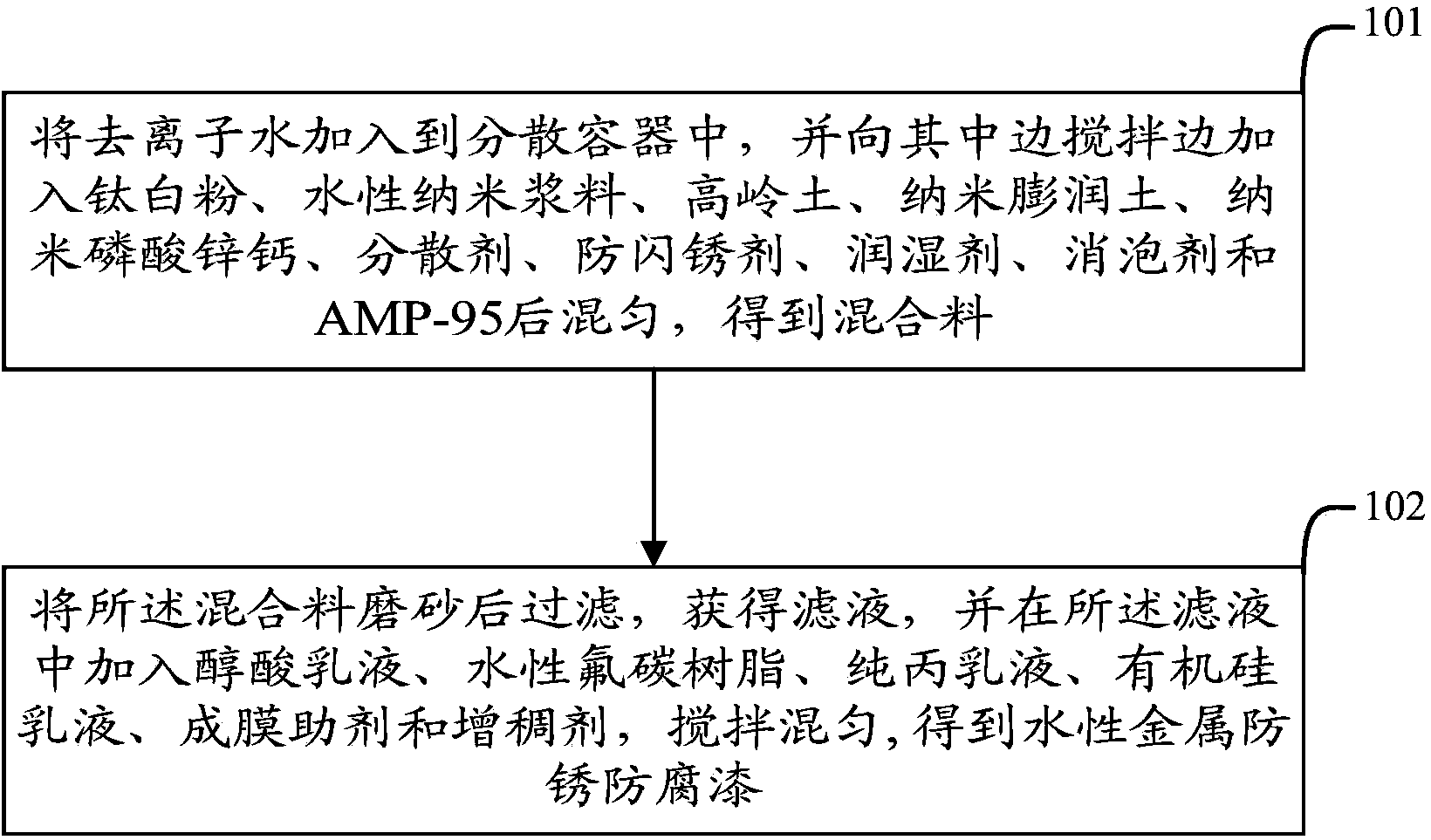

Method used

Image

Examples

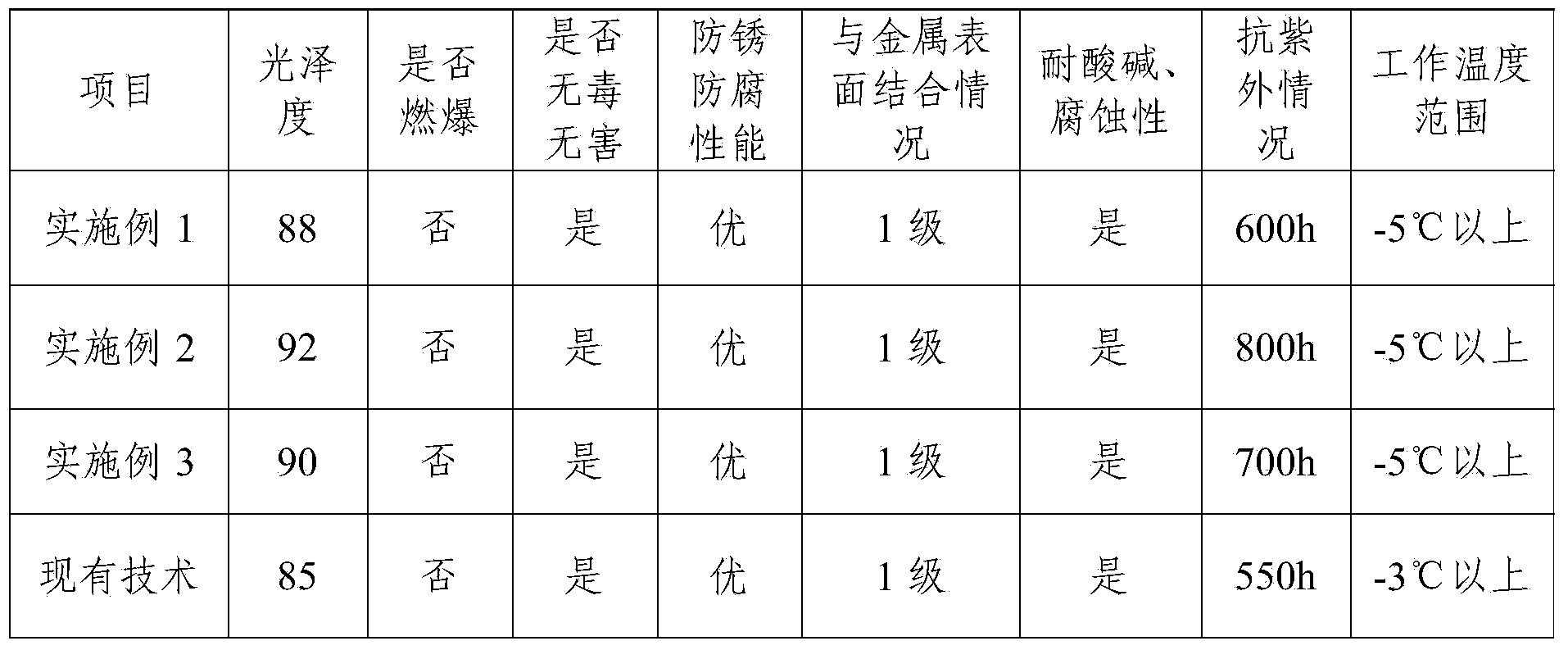

Embodiment 1

[0026] The water-based metal anti-rust and anti-corrosion paint of the present embodiment, according to parts by weight, its raw material components include: 200 parts of deionized water, 180 parts of titanium dioxide, 60 parts of water-based nano slurry, 20 parts of kaolin, 20 parts of nano-bentonite, 8 parts of nano-calcium zinc phosphate, 40 parts of alkyd emulsion, 80 parts of water-based fluorocarbon resin, 150 parts of pure acrylic emulsion, 20 parts of silicone emulsion, 10 parts of propylene glycol, 1 part of nano-silica, 4 parts of dispersant, film-forming 10 parts of additives, 2 parts of defoamer, 2 parts of leveling agent, 1 part of thickener, 1 part of anti-flash rust agent, 1 part of AMP-951, 1 part of wetting agent.

Embodiment 2

[0028] The water-based metal anti-rust and anti-corrosion paint of the present embodiment, in parts by weight, its raw material components include: 225 parts of deionized water, 200 parts of titanium dioxide, 80 parts of water-based nano slurry, 30 parts of kaolin, 30 parts of nano-bentonite, 10 parts of nano zinc calcium phosphate, 50 parts of alkyd emulsion, 100 parts of water-based fluorocarbon resin, 190 parts of pure acrylic emulsion, 50 parts of silicone emulsion, 20 parts of propylene glycol, 2 parts of nano silicon dioxide, 5 parts of dispersant, film forming 20 parts of additives, 3 parts of defoamer, 2 parts of leveling agent, 2 parts of thickener, 2 parts of anti-flash rust agent, 1 part of AMP-951, 2 parts of wetting agent.

Embodiment 3

[0030]The water-based metal anti-rust and anti-corrosion paint of the present embodiment, according to parts by weight, its raw material components include: 250 parts of deionized water, 220 parts of titanium dioxide, 100 parts of water-based nano slurry, 40 parts of kaolin, 40 parts of nano-bentonite, 15 parts of nano zinc calcium phosphate, 60 parts of alkyd emulsion, 130 parts of water-based fluorocarbon resin, 200 parts of pure acrylic emulsion, 60 parts of silicone emulsion, 30 parts of propylene glycol, 3 parts of nano silicon dioxide, 8 parts of dispersant, film forming 40 parts of additives, 5 parts of defoamer, 4 parts of leveling agent, 4 parts of thickener, 3 parts of anti-flash rust agent, 2 parts of AMP-952, 2 parts of wetting agent.

[0031] In addition, in combination with all the above-mentioned embodiments, as a further technical solution, preferably, the titanium dioxide is: R-930 titanium dioxide; the pure acrylic emulsion is pure acrylic emulsion GM-115; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com