Edge grinding system for tableware processing

A tableware and station technology, which is applied in the field of rim system for tableware processing, can solve the problems of complicated installation and debugging, high labor intensity, low processing efficiency, etc., and achieves the effects of convenient debugging, reduced labor intensity, and convenient installation and debugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

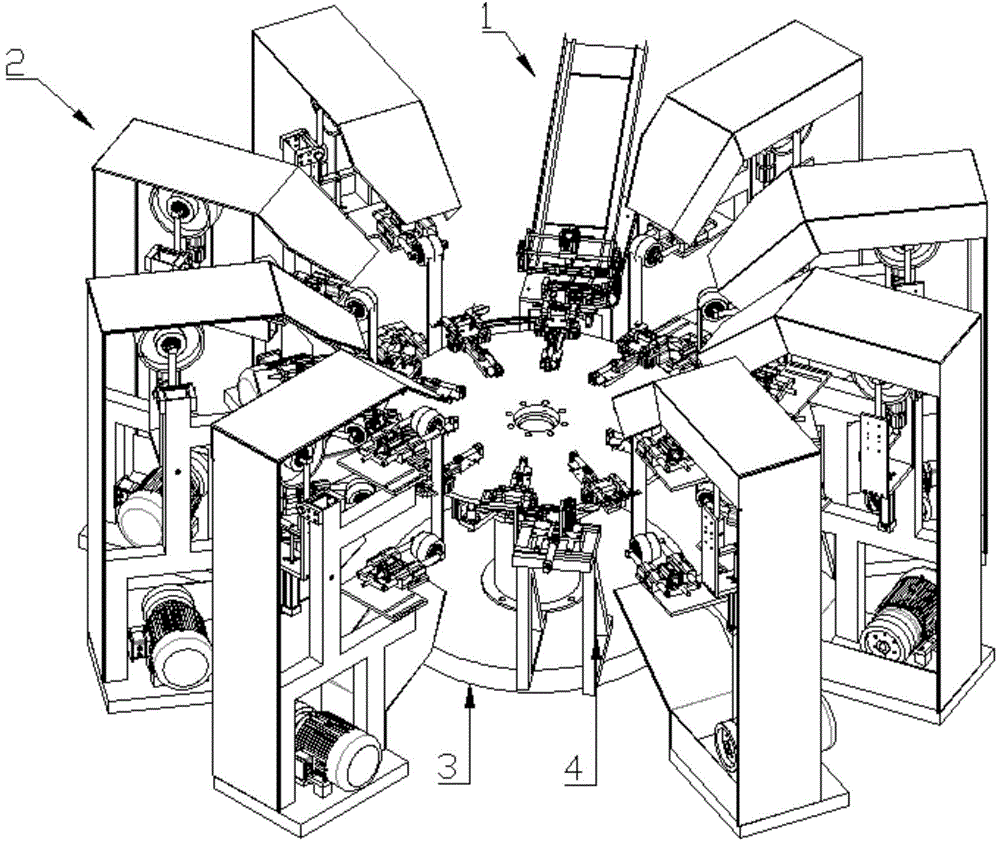

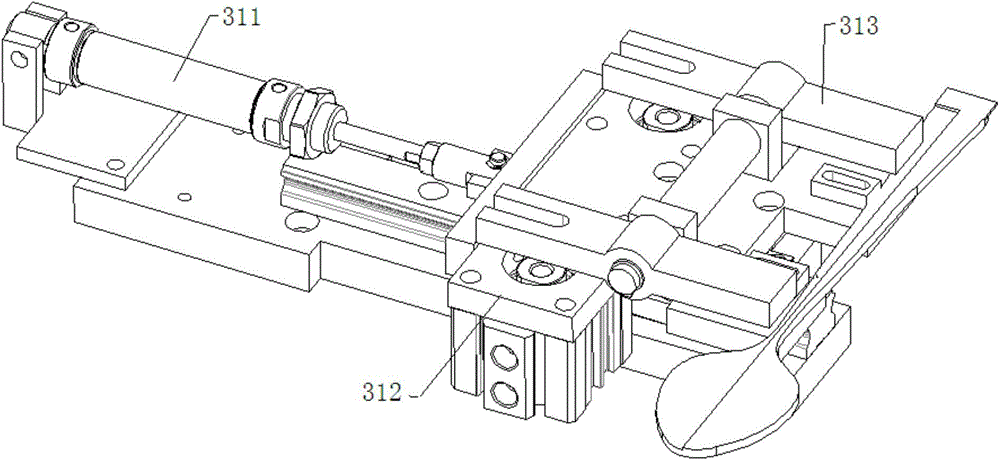

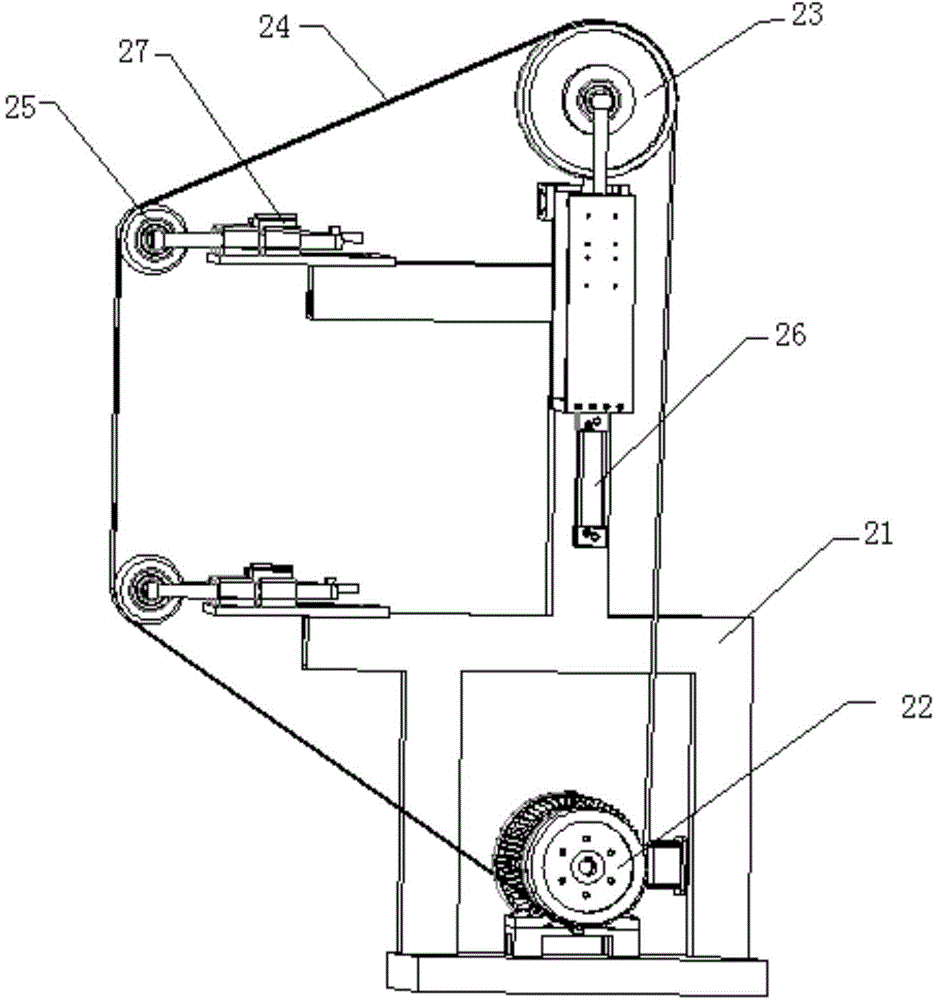

[0024] The specific embodiment of the present invention is described according to accompanying drawing now, as Figure 1-7 As shown, a ring edge system 2 for tableware processing includes a circular rotary material circulation device 3, the outer side of the material circulation device 3 is provided with a feeding station 1, and the outer side of the material circulation device 3 is evenly equipped with Two groups of grinding stations, and the two groups of grinding stations are arranged symmetrically with the line connecting the center line of the feeding station 1 and the center of the circular rotary material circulation equipment 3, each group of grinding stations There are a plurality of grinding devices 2, the material circulation equipment 3 includes a base 32, the middle of the base 32 is provided with a support column 33, and the support column 33 is provided with a servo motor and a reducer connected thereto. The reducer is connected to a turntable 34 through a slewi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com