Preparation method of heterojunction mvo4 and tio2 composite photocatalytic fiber

A composite photocatalysis and heterojunction technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of high carrier recombination probability and difficult high efficiency Using solar energy, limiting photocatalytic efficiency and other issues, to achieve the effect of reduced band gap energy, simple and easy-to-control preparation method, and high-efficiency photocatalytic degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Measure 20mL of HF solution with a mass fraction of 4% and put it into a 100mL stainless steel hydrothermal kettle lined with a polytetrafluoroethylene reaction tube, and insert a polytetrafluoroethylene sieve net at the top of the reaction tube, the sieve net The aperture of the sieve is 4mm, and the opening rate is 42%; use tweezers to dope 75mg Si into TiO 2 Spread the fiber raw material evenly on the sieve net, seal the hydrothermal reaction kettle and transfer it to an oven, and conduct a hydrothermal reaction at 90°C for 4 hours. After the reaction, take out the Si-doped TiO 2 The fibers were washed three times with deionized water and absolute ethanol to obtain roughened Si-doped TiO 2 fiber, spare.

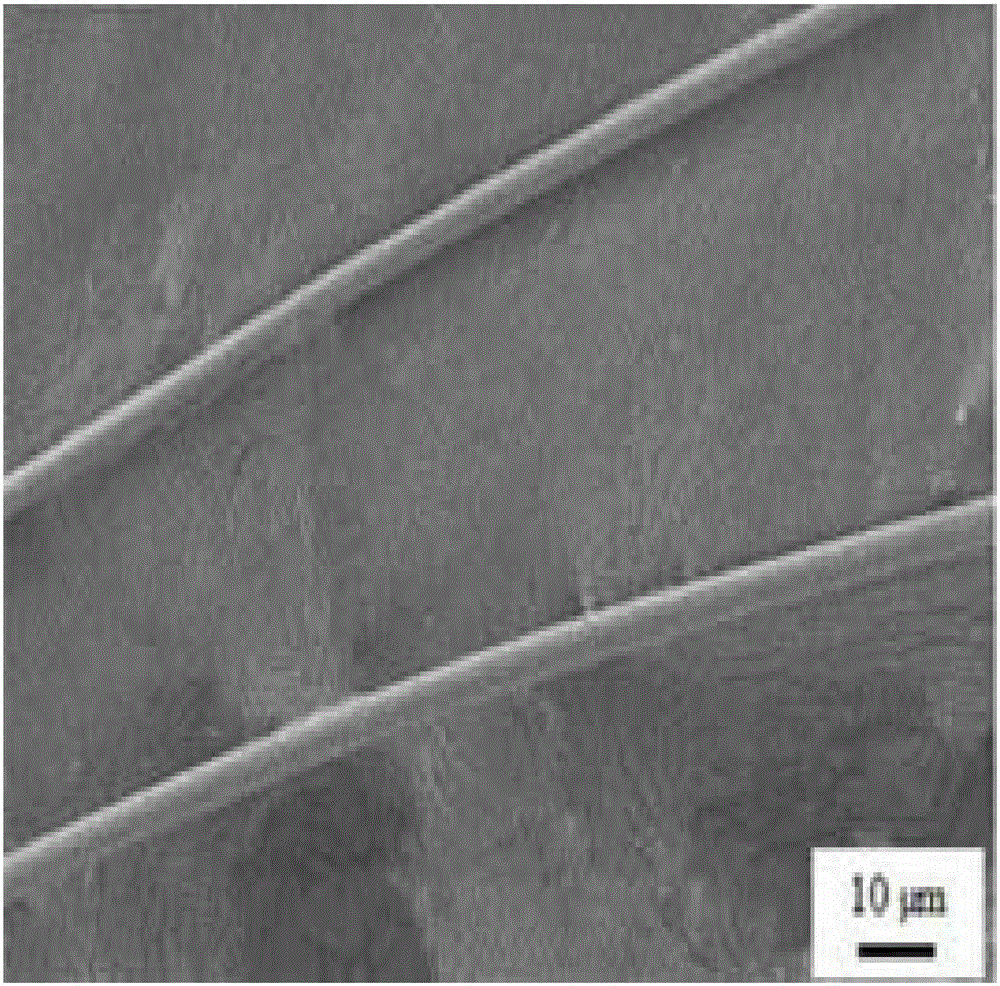

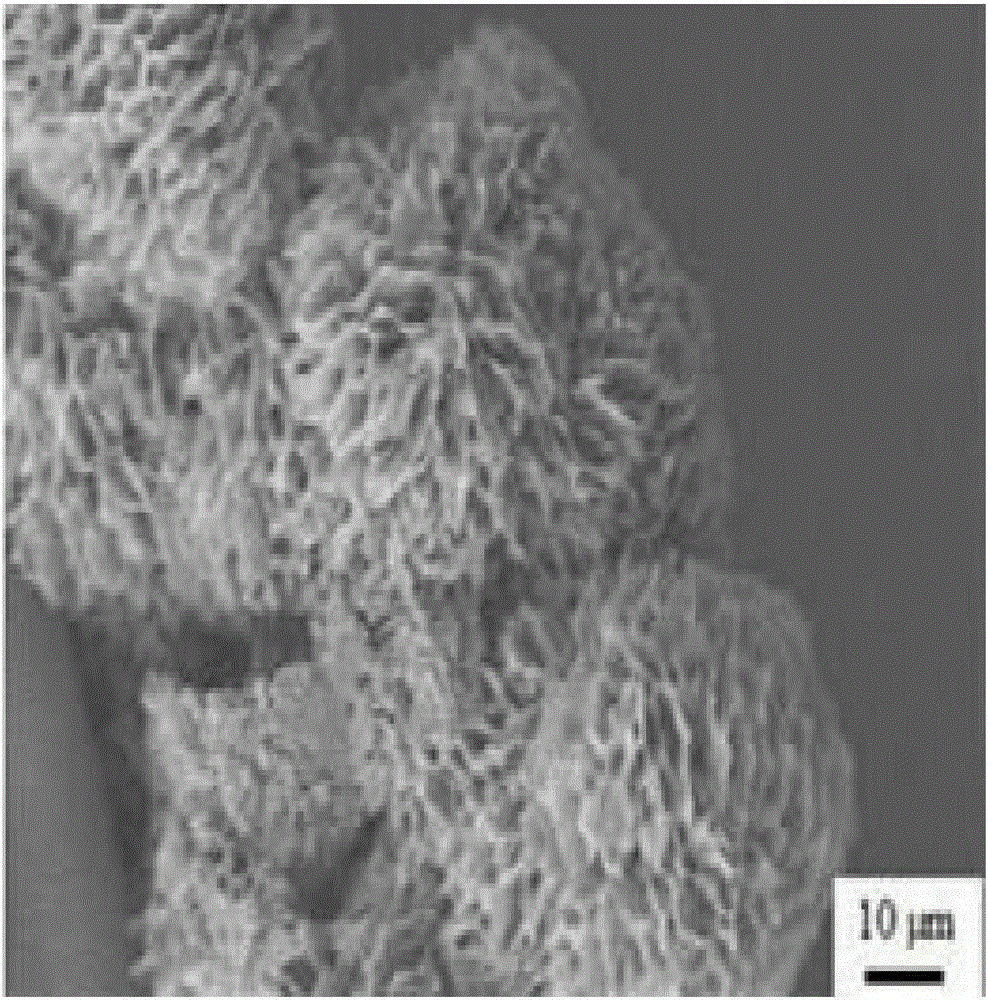

[0041] figure 1 roughened TiO 2 Scanning electron microscope image of a fiber.

[0042] (2) Weigh 0.0511gIn(NO 3 ) 3 and 0.0451g vanadyl acetylacetonate (0.0511gIn(NO 3 ) 3 , 0.0451g vanadyl acetylacetonate and 75mg Si-doped TiO with roughened surface 2...

Embodiment 2

[0048] (1) The difference between this step and step (1) in Example 1 is to weigh 150mg Si-doped TiO 2 The fiber raw material is evenly spread on the sieve mesh, and the Si-doped TiO with roughened surface is obtained. 2 fiber;

[0049] (2) Weigh 0.1218gIn(NO 3 ) 3 With 0.0716g vanadyl acetylacetonate (0.1218gIn(NO 3 ) 3 , 0.0716g vanadyl acetylacetonate and 150mg surface-roughened Si-doped TiO 2 The molar ratio of the fiber is 1.5:1:7) was successively added and dissolved in 30 mL of absolute ethanol, and magnetically stirred for 1 hour to obtain the indium vanadate precursor solution A. Take by weighing the surface-roughened TiO that step (1) makes 2 150 mg of fiber was placed in the above-mentioned solution A, and ultrasonically oscillated for 30 minutes to prepare multi-phase mixed solution B.

[0050] (3) This step is the same as step (3) in Example 1.

[0051] (4) This step is the same as step (4) in Example 1. Adopt the microwave hydrothermal reaction identical...

Embodiment 3

[0054] (1) Measure 20 mL of HF solution with a mass fraction of 6% and transfer it to 100 mL of the aforementioned hydrothermal reaction kettle, insert a sieve mesh, and use tweezers to dope 130 mg of Si into TiO 2 Spread the fiber raw material evenly on the sieve net, seal the hydrothermal reaction kettle and transfer it to an oven, and conduct a hydrothermal reaction at 100°C for 3 hours. After the reaction, take out the Si-doped TiO 2 The fibers were washed three times with deionized water and absolute ethanol respectively to obtain roughened Si-doped TiO 2 fiber, spare.

[0055] (2) Weigh 0.0924gFe(NO 3 ) 3 With 0.0716g vanadyl acetylacetonate (0.0924gFe(NO 3 ) 3 Doped TiO with 0.0716 g vanadyl acetylacetonate and 130 mg surface-roughened Si 2 The molar ratio of fiber is 1.5:1:6) was successively added and dissolved in 30mL of absolute ethanol, and magnetically stirred for 1 hour to obtain FeVO 4 Precursor A. Take by weighing the surface-roughened TiO that step (1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com