SnS2 nanosheet as well as preparation method and application thereof

A nano-sheet and sheet-like technology, which is applied in the field of SnS2 nano-sheet preparation, can solve problems such as lack of research, and achieve the effects of low cost, short adsorption equilibrium time, and simple process preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of SnS 2 The preparation method of nano sheet, comprises the following steps:

[0029] (1) Dissolve 2mmol sodium diethyldithiocarbamate trihydrate (copper reagent) in an acidic solution mixed with 25mL ethylene glycol and 5mL glacial acetic acid, then add 1mmol SnCl 4 ·5H 2 O, continued to stir for 10 min to a colorless solution.

[0030] (2) The liquid was then transferred to a 50 mL polytetrafluoroethylene-lined stainless steel reactor, sealed and heated at 160 °C for 12 h, and cooled to room temperature naturally. The yellow precipitate was collected by centrifugation, washed several times with deionized water and absolute ethanol, and finally dried in a vacuum oven at 60 °C for 12 h.

[0031] Product structure and morphology characterization

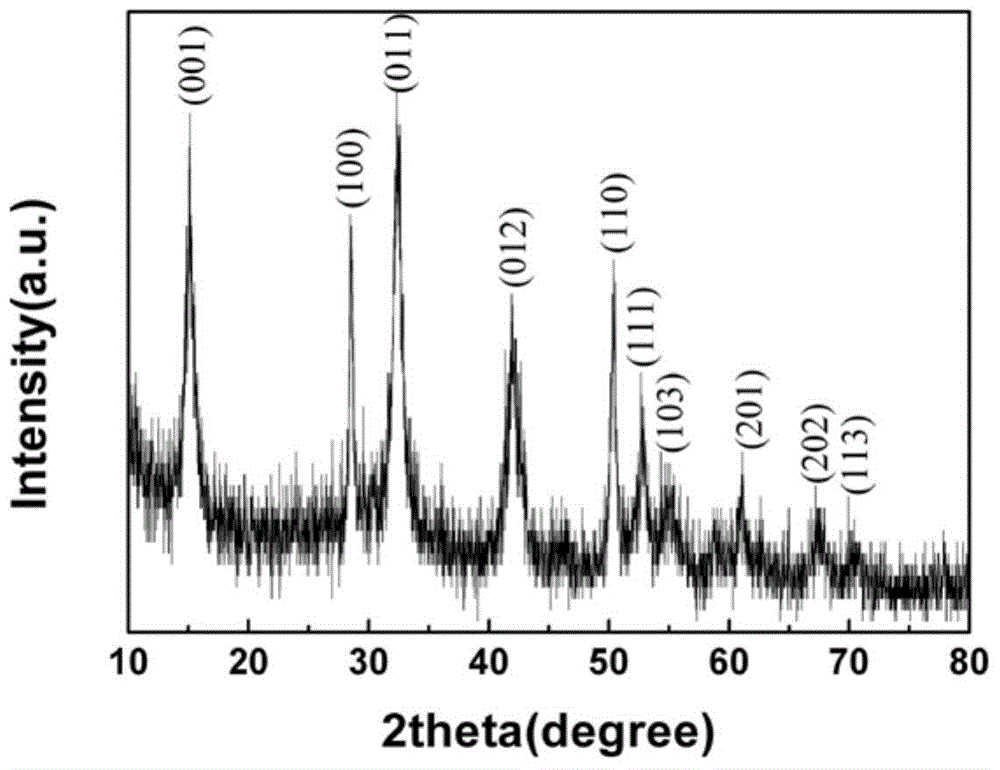

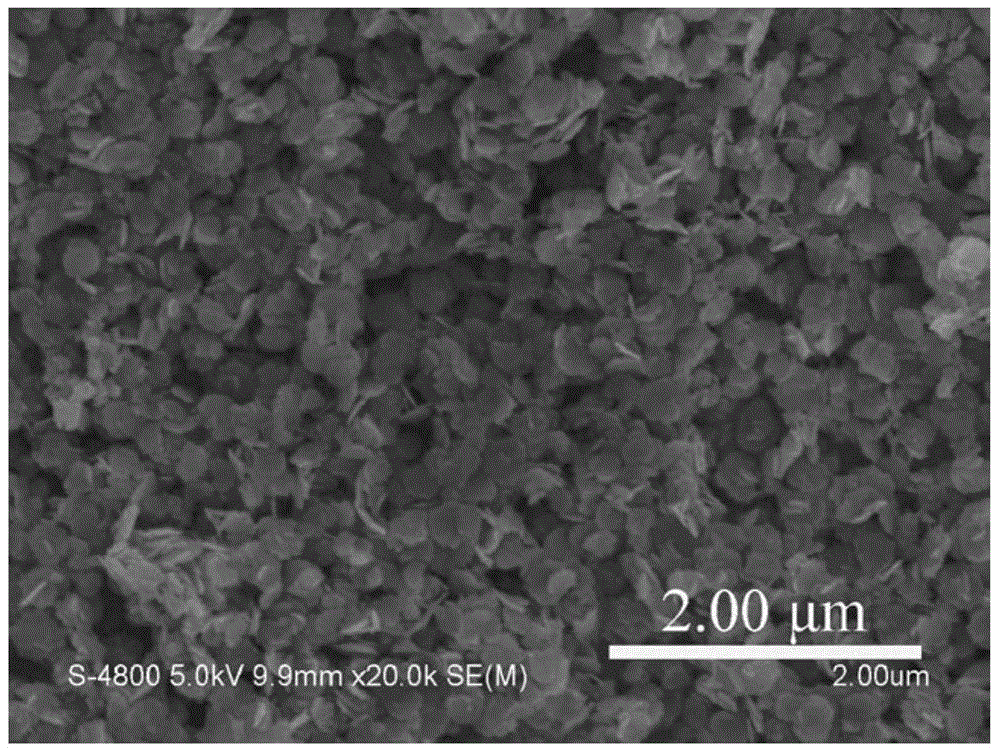

[0032] Use Rigaku TTRIIII X-ray powder diffractometer to carry out phase identification to embodiment 1 gained product (Cu target), as figure 1 shown. Compared with the JCPDS standard card (83-1705), all the diffr...

Embodiment 2

[0034] A kind of SnS 2 The application of nanosheet adsorption and visible light catalytic degradation of organic dyes, taking methylene blue organic dyes as an example.

[0035] Adsorption test method: the 10mg SnS prepared in Example 1 2 The nanosheets were added to 150mL of 0.025mmol / L methylene blue solution, placed in a dark place, ultrasonicated for 1-2 minutes, and kept stirring with a magnetic stirrer to keep them evenly dispersed in the solution. After 20 min, the adsorption-desorption equilibrium was reached, and a 5 mL sample was taken, centrifuged (10000 rpm, 2 min), and the supernatant was taken. By measuring the spectrogram of ultraviolet absorption, calculate the adsorption amount, which is 66.6%, the result is as follows Figure 6 , 7 shown.

[0036]Photodegradation test method: irradiate the solution after reaching adsorption-desorption equilibrium with a 300W xenon lamp (λ>420nm) as visible light. Take 5mL solution every 10min, after centrifugation (1000...

Embodiment 3

[0038] A kind of SnS 2 The preparation method of nano sheet, comprises the following steps:

[0039] (1) Dissolve 2mmol sodium diethyldithiocarbamate trihydrate (copper reagent) in an acidic solution mixed with 15mL ethylene glycol and 5mL glacial acetic acid, then add 1.9mmol SnCl 4 ·5H 2 O, continued to stir for 10 min to a colorless solution.

[0040] (2) The liquid was then transferred to a 50 mL polytetrafluoroethylene-lined stainless steel reactor, sealed and heated at 140 °C for 15 h, and cooled to room temperature naturally. The yellow precipitate was collected by centrifugation, washed several times with deionized water and absolute ethanol, and finally dried in a vacuum oven at 60 °C for 12 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com