Preparation method and application of la-activated functionalized dendritic mesoporous silica nanospheres

A technology of mesoporous silica and nanospheres, applied in silica, silica, chemical instruments and methods, etc., can solve the problems of low adsorption capacity and adsorption rate of decontamination materials, difficult regeneration, coexisting ion interference, etc. , to achieve good recycling performance, improve utilization efficiency, high-efficiency selective adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation method of La-activated functionalized dendritic mesoporous silica nanospheres comprises the following steps:

[0045] 1. Preparation of Dendritic Mesoporous Silica Nanospheres

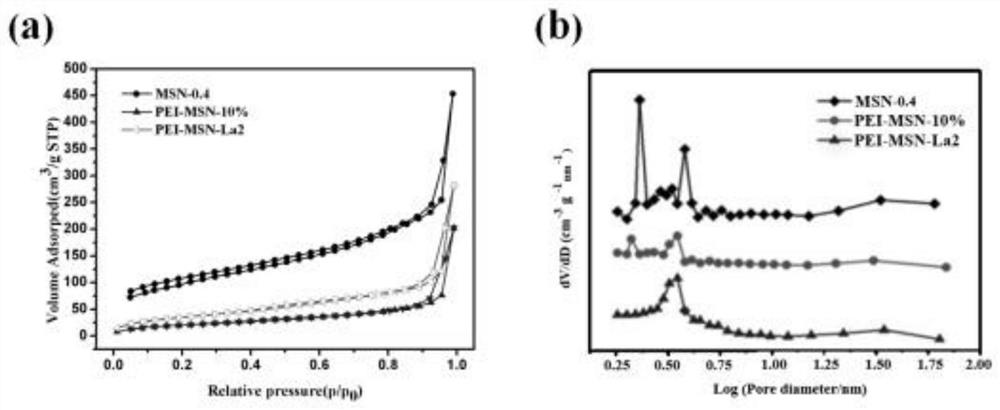

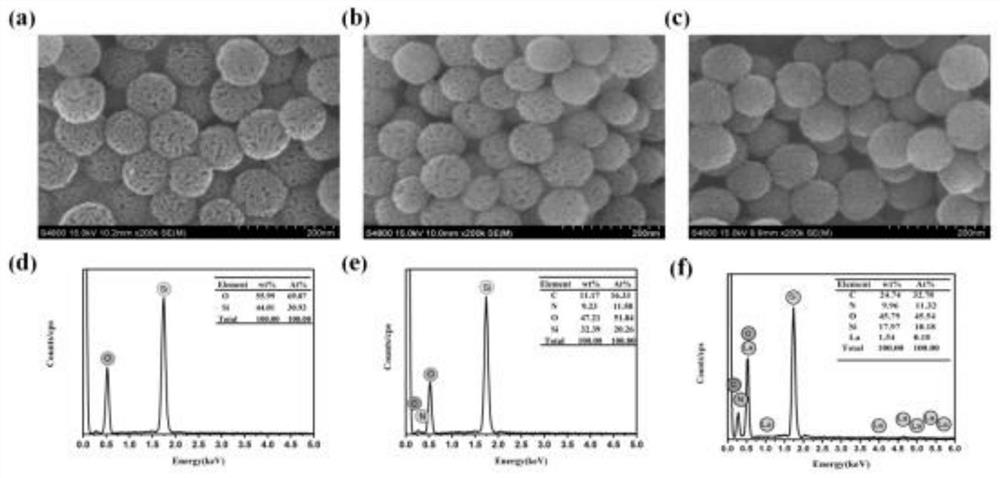

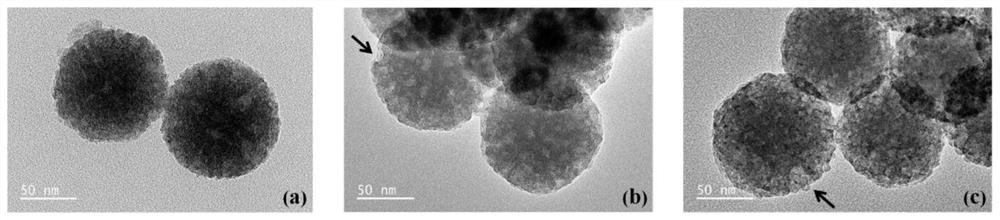

[0046] 380mg CTAB and a certain amount of FC 2 (molar ratio FC 2 : CTAB=0.2, 0.4, and 0.5.) was added to 25 ml of deionized water in which 68 mg of TEA was dissolved, and stirred at 80° C. for 1 hour. Then, 4 ml of TEOS was added dropwise under this condition, and stirring was kept for 2 h. The mixture was centrifuged at 7500 rpm for 40 minutes, then the product was washed three times with a 1:1 ethanol:water solution and dried at 60°C overnight. The obtained product was calcined at 550 °C for 6 hours to remove the surfactant, and the product was named MSN-x (x=0.2, 0.4, 0.5), where x is FC 2 and CTAB molar ratio.

[0047] 2. Preparation of PEI-grafted dendritic mesoporous silica nanospheres

[0048] 0.5g of MSN was added to 10ml of PEI / methanol solution (w / v=5, 10 or 15%) ...

Embodiment 2

[0052] The preparation method of La-activated functionalized dendritic mesoporous silica nanospheres comprises the following steps:

[0053] 1. Preparation of Dendritic Silica Nanospheres

[0054] 380mg CTAB and a certain amount of FC 2 (molar ratio FC 2 : CTAB=0.2, 0.4, and 0.5.) was added to 25 ml of deionized water in which 68 mg of TEA was dissolved, and stirred at 80° C. for 1 hour. Then, 4 ml of TEOS was added dropwise under this condition, and stirring was kept for 2 h. The mixture was centrifuged at 7500 rpm for 40 minutes, then the product was washed three times with a 1:1 ethanol:water solution and dried at 60°C overnight. The obtained product was calcined at 550 °C for 6 hours to remove the surfactant, and the product was named MSN-x (x=0.2, 0.4, 0.5), where x is FC 2 and CTAB molar ratio.

[0055] 2. Preparation of PEI-grafted Mesoporous Silica

[0056] 0.5g of MSN was added to 10ml of PEI / methanol solution (w / v=5, 10 or 15%) and stirred at 30°C for 10 hours....

Embodiment 3

[0060] The preparation method of La-activated functionalized dendritic mesoporous silica nanospheres comprises the following steps:

[0061] 1. Preparation of Dendritic Silica Nanospheres

[0062] 380mg CTAB and a certain amount of FC 2 (molar ratio FC 2 : CTAB=0.2, 0.4, and 0.5.) was added to 25 ml of deionized water in which 68 mg of TEA was dissolved, and stirred at 80° C. for 1 hour. Then, 4 ml of TEOS was added dropwise under this condition, and stirring was kept for 2 h. The mixture was centrifuged at 7500 rpm for 40 minutes, then the product was washed three times with a 1:1 ethanol:water solution and dried at 60°C overnight. The obtained product was calcined at 550 °C for 6 hours to remove the surfactant, and the product was named MSN-x (x=0.2, 0.4, 0.5), where x is FC 2 and CTAB molar ratio.

[0063] 2. Preparation of PEI-grafted dendritic mesoporous silica nanospheres

[0064] 0.5g of MSN was added to 10ml of PEI / methanol solution (w / v=5, 10 or 15%) and stirred...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com