Water injection device for a bypass steam system of a power plant

A technology of water spraying equipment and steam system, applied in steam superheating, mechanical equipment, steam generation, etc., can solve problems such as condenser damage, achieve good cooling effect, avoid accumulation, improve atomization and mixing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

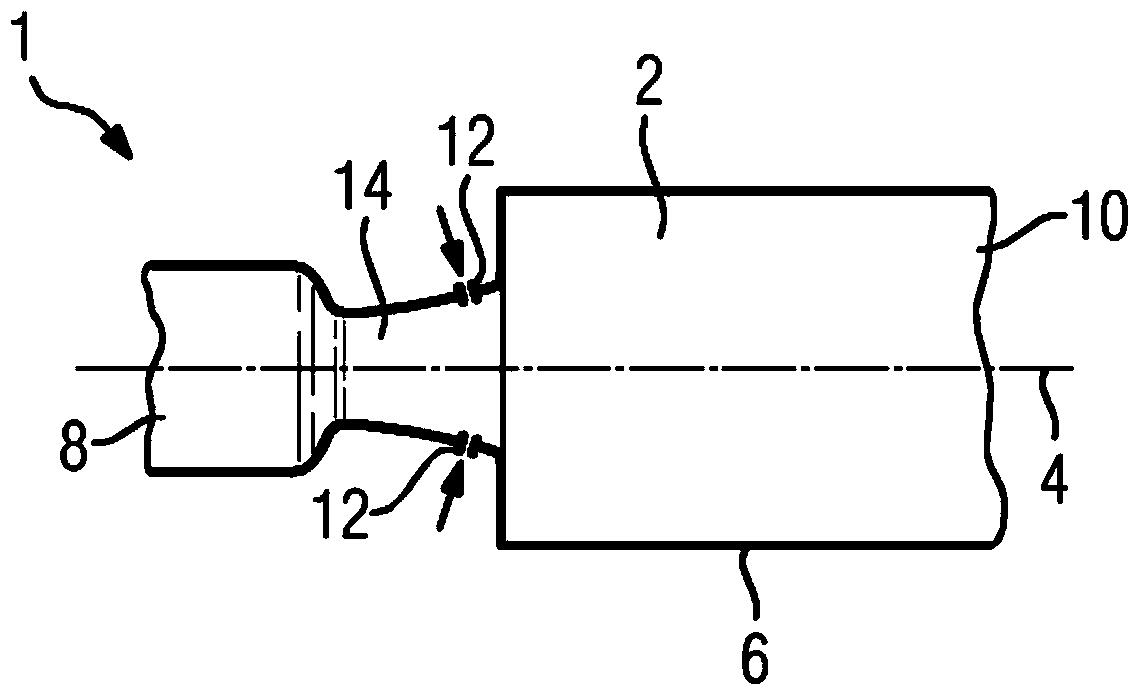

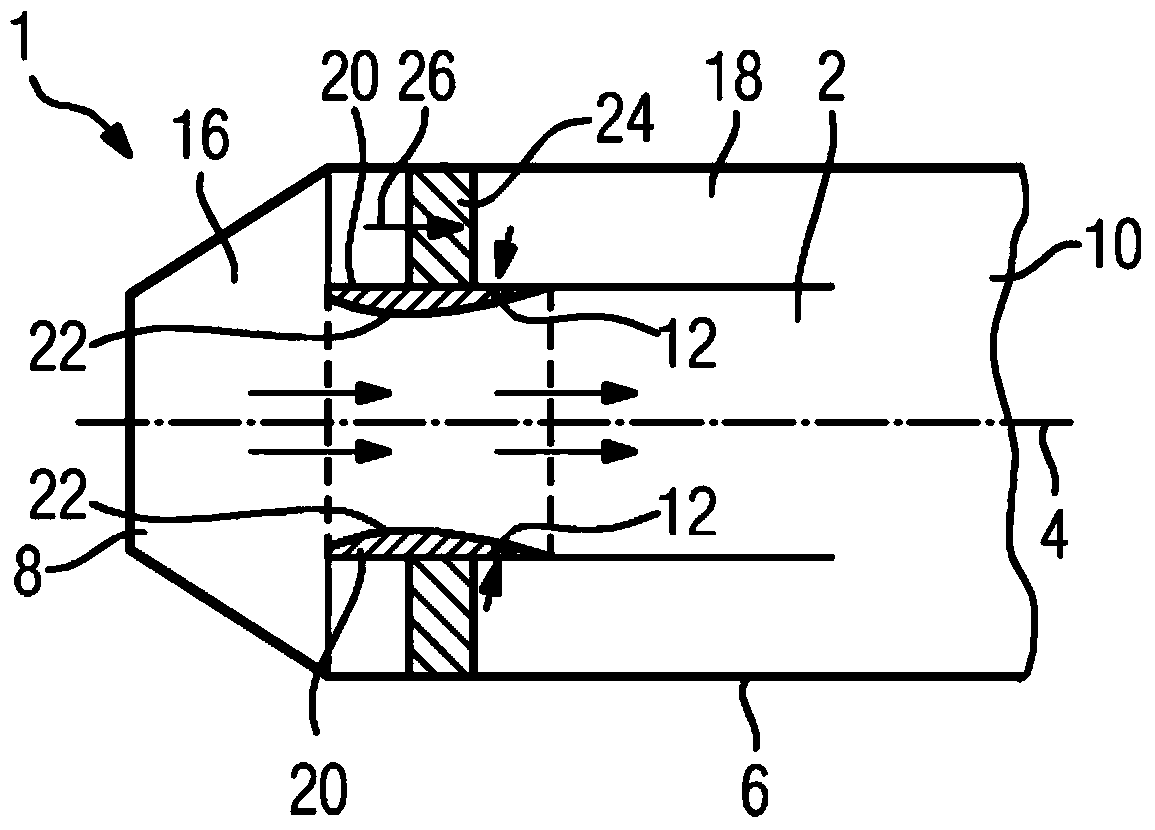

[0021] according to figure 1 The sprinkler device 1 comprises a flow channel 2 surrounded by an inner wall 6 arranged radially symmetrically about an axis 4 . Steam inlet 8 in figure 1 The center is on the left, and the steam outlet 10 is on the right. The cross section of the steam inlet 8 is smaller than the cross section of the steam outlet 10 . This achieves the effect that the underexpanded strands generated after the converging nozzle 14 do not touch the inner wall 6 .

[0022] The water injection system 1 is part of a bypass steam system of a power plant, which is not shown in detail. Not shown is a bypass valve connected upstream of the steam inlet 8, by means of which the steam flow from the steam generator of the power plant is directly introduced into the steam outlet 10 via the bypass steam system bypassing the steam turbine into the downstream condenser. This can be necessary in certain situations, for example when the steam turbine starts up or after a trip....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com