High-voltage light emitting diode chip and manufacturing method thereof

A technology of high-voltage light-emitting and manufacturing methods, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of inability to connect the overall diode, disconnection of metal wires, low luminous efficiency, etc. The effect of increasing single-chip output and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Please refer to Figure 1~6 , the present invention is a schematic flow diagram of making a high-voltage light-emitting diode chip, and its implementation steps include:

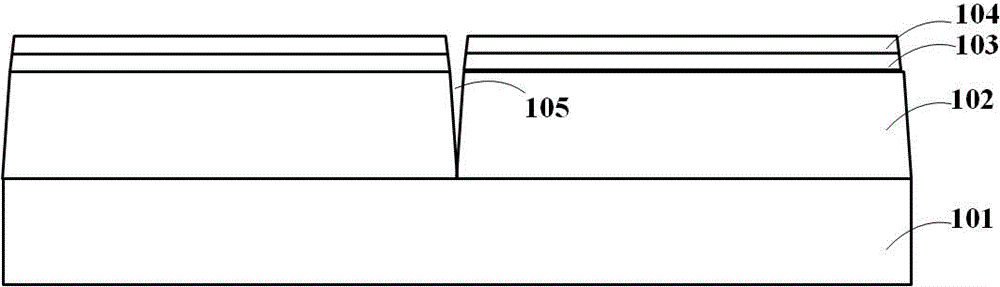

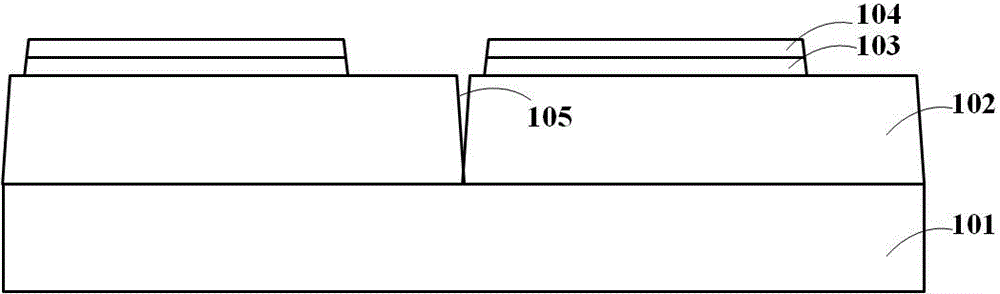

[0061] Please refer to figure 1 , providing a substrate 101 for epitaxial growth, preferably a sapphire insulating substrate, aluminum nitride or other non-conductive substrates can also be selected; a light-emitting epitaxial stack is formed on the substrate 101 through a metal organic compound chemical vapor deposition process , comprising an N-type semiconductor layer 102, a light emitting layer 103 and a P-type semiconductor layer 104 in order from bottom to top;

[0062] Please refer to figure 2 , using a dry / wet etching process to pattern the light-emitting epitaxial stack and form a V-shaped ultra-narrow trench 105 until the surface of the substrate 101 is exposed, thereby separating the light-emitting epitaxial stack into a plurality of circular light-emitting units (There are only 2 light...

Embodiment 2

[0070] Please refer to Figure 7~12 , the present invention is a schematic flow diagram of making a high-voltage light-emitting diode chip, and its implementation steps include:

[0071] Please refer to Figure 7 , providing a substrate 201 for epitaxial growth, preferably a sapphire insulating substrate; through a metal organic compound chemical vapor deposition process, a light-emitting epitaxial stack is formed on the substrate 201, including an N-type semiconductor layer 202, a light-emitting layer from bottom to top Layer 203 and P-type semiconductor layer 204;

[0072] Please refer to Figure 8 , using a dry / wet etching process to pattern the light-emitting epitaxial stack and form a V-shaped ultra-narrow trench 205 until the surface of the substrate 201 is exposed, thereby separating the light-emitting epitaxial stack into a plurality of rectangular light-emitting units , forming a light-emitting diode wafer in this way, wherein the light-emitting unit sequentially i...

Embodiment 3

[0079] Please refer to Figure 13 , compared with Embodiment 2, the electrode interconnection wire 309 of this embodiment straddles the opening end of the ultra-narrow trench and is not attached to the sidewall in the ultra-narrow trench, but does not extend to the corresponding On the sidewall of part of the light-emitting epitaxial stack adjacent to the light-emitting unit, the electrode interconnection line 309 connects the adjacent light-emitting units in parallel through the N electrode 307 of the adjacent light-emitting unit. Since the liquid conductive material layer is introduced, after solidification, it directly straddles the opening end of the ultra-narrow trench and does not adhere to the sidewall in the ultra-narrow trench, so the conventional light-emitting epitaxy stack side can be omitted. The insulating material layer between the wall and the electrode interconnection wires simplifies the manufacturing process and saves manufacturing costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com