Determination method of phosphorus content in niobium-containing steel

A method of determination, a technology of phosphorus content, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions. It can solve problems such as cumbersome operations, threats to the physical and mental health of operators, and environmental pollution. , to achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Hereinafter, the method for determining phosphorus content in niobium-containing steel according to the present invention will be described in detail with reference to exemplary embodiments.

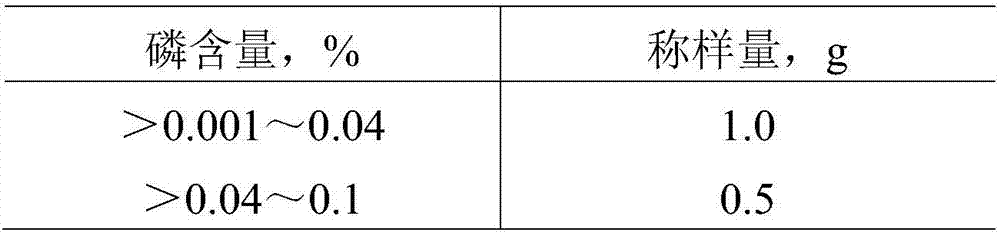

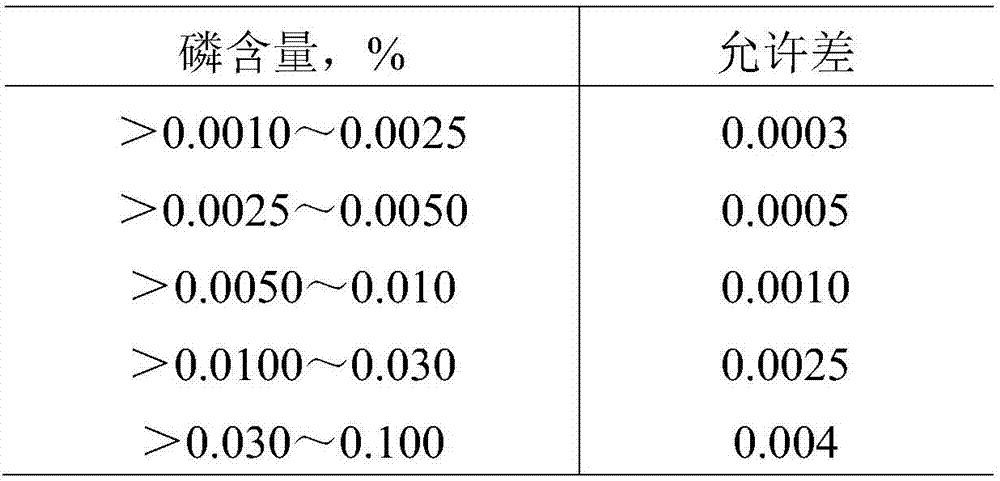

[0010] In the present invention, the niobium-containing steel to be tested contains 0.001% to 0.1% phosphorus content by mass percentage and the tungsten element content should not be greater than 0.25%. In addition, the niobium-containing steel can also contain niobium, nickel, cobalt, chromium, elements such as manganese and copper.

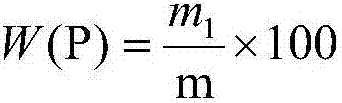

[0011] In an exemplary embodiment of the present invention, the determination method of phosphorus content in niobium-containing steel comprises the following steps carried out in order:

[0012] Acid hydrolysis of niobium-containing steel to obtain acid hydrolysis solution. The acid used for acidolysis should include an oxidizing acid (for example, nitric acid), preferably a mixed acid. For example, a mixed acid of hydrochloric acid and nitric a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com