Humidification desulphurization sweeping device for tail flue of coal-fired boiler

A tail flue and coal-fired boiler technology, applied in the desulfurization field of coal-fired boilers, can solve problems such as increased operational difficulty, flue blockage, increased flue gas discharge resistance, and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

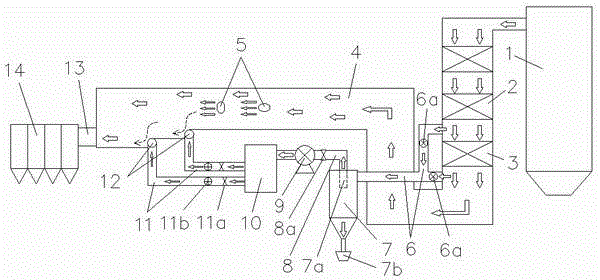

[0012] The working principle of a coal-fired boiler tail flue humidification desulfurization purging device is as follows: figure 1 , 2 As shown, the device mainly includes: gas transmission pipeline 6, cyclone separator 7, gas transmission pipeline 8, induced draft fan 9, flue gas header 10, gas transmission branch pipe 11, gas outlet communication pipe 12, pipeline 13, etc. The front end of the gas pipeline 6 is respectively connected to the outlet flue of the economizer 2 and the outlet flue of the air preheater 3, and the end of the gas pipeline 6 is connected tangentially to the cyclone separator 7, and the gas volume regulating valve 6a is set on the gas pipeline 6 , the bottom of the cyclone separator 7 is provided with a fly ash storage tank 7b; the cyclone separator 7 is connected to the induced draft fan 9 through the upper gas transmission pipeline 8, the upper gas transmission pipeline 8 is provided with a flow meter 8a, the induced draft fan 9 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com