Light LED lamp efficient in heat dissipation

A technology of LED lamps and LED lamps, applied in lighting and heating equipment, parts of lighting devices, semiconductor devices of light-emitting elements, etc., can solve the problems of low heat radiation heat dissipation efficiency, complex heat convection structure, and inability to dissipate heat, etc. Achieve the effect of improving heat conduction, reducing support strength and production cost, improving service life and aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

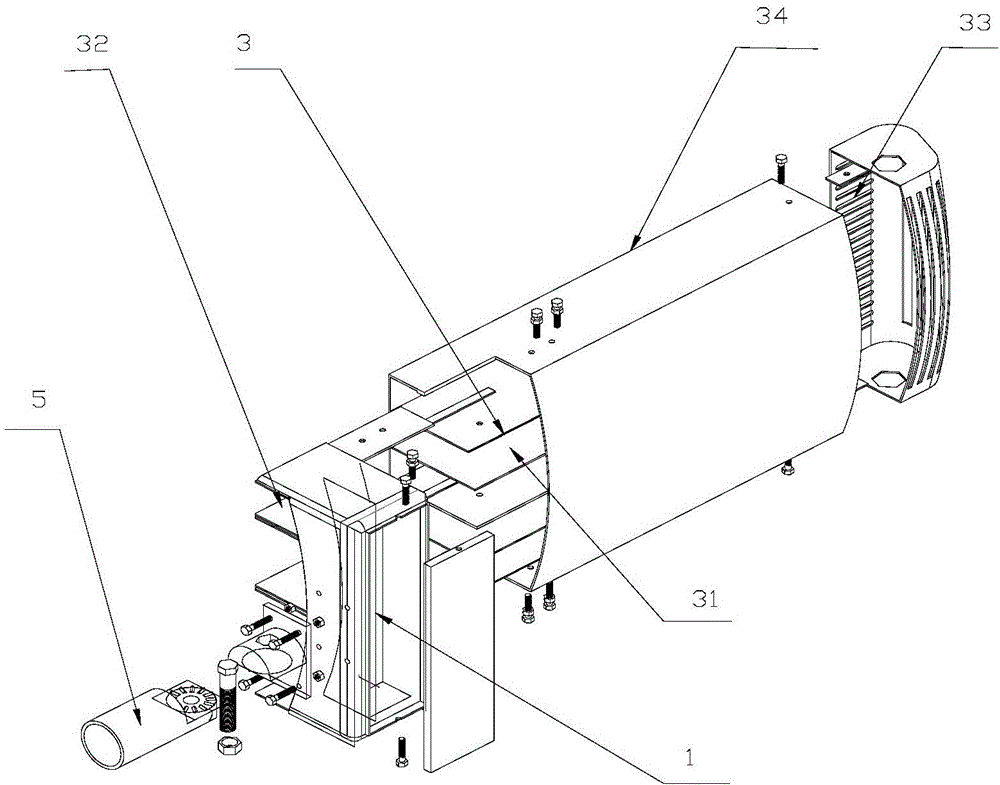

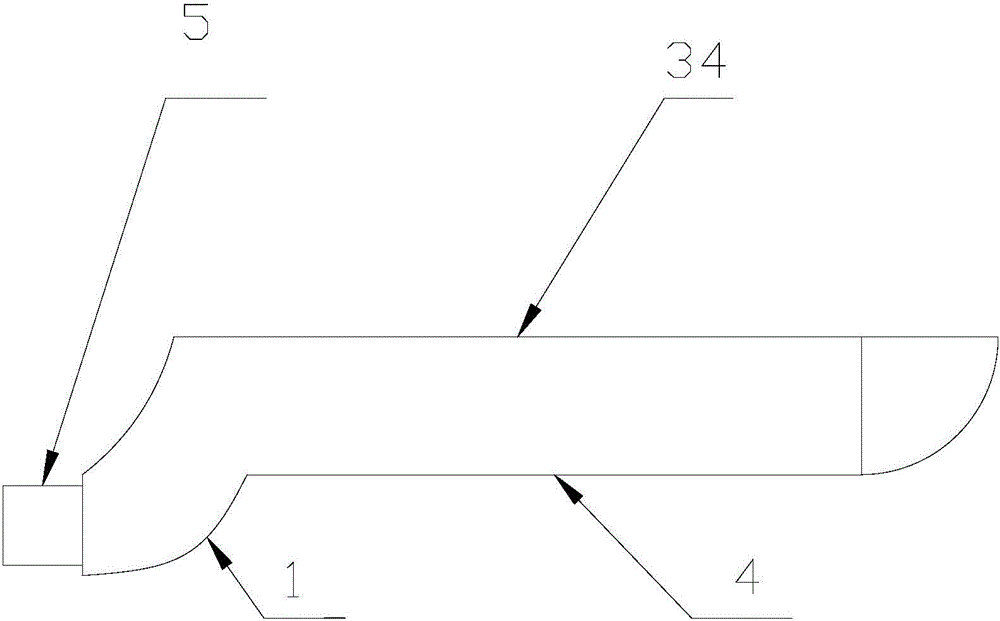

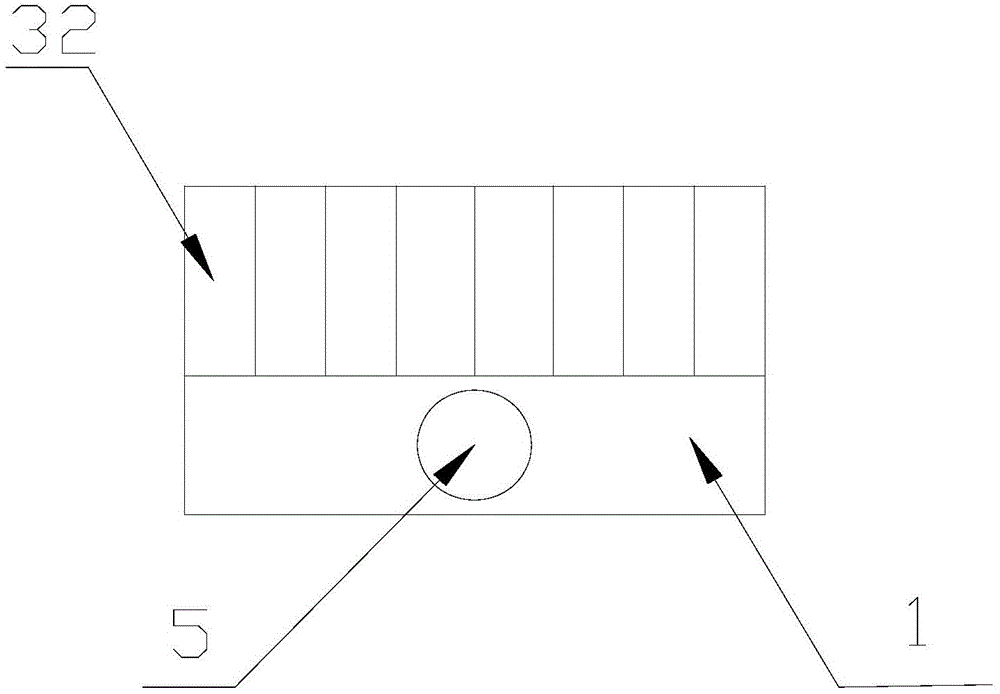

[0045] Such as Figure 1~5 As shown, this embodiment is a light-weight and efficient heat-dissipating LED lamp for street lamps, including a lamp holder 1, an LED lamp substrate 2 and a radiator 3, the lamp holder 1 is connected to the radiator 3, and the lamp holder 1 is provided with a connector 5 connected to the outside world, the LED lamp substrate 2 is provided with a plurality of LED lamps, and the heat sink 3 is provided with 8 heat dissipation channels 31, and a part of the heat dissipation channels is composed of The LED lamp substrate 2 is formed, and the other parts are formed by the first heat conduction layer 34. The material of the first heat conduction layer 34 is aluminum alloy, and the thickness of the first heat dissipation layer 34 is 0.3 mm. In actual use, The first heat dissipation layer 34 is located above the LED lamp substrate 2, and the heat dissipation channel 31 is provided with an air inlet 32 and an air outlet 33, and the distribution density of...

Embodiment 2

[0050] Such as Figure 8 to Figure 9 As shown, this embodiment is a bulb-shaped LED lamp with light weight and high efficiency of heat dissipation, including a lamp holder 1, an LED lamp substrate 2 and a radiator 3, the lamp holder 1 is connected to the radiator 3, and the lamp holder 1 is provided with a connector 5 connected to the outside world, the LED lamp substrate 2 is provided with a plurality of LED lamps, and the heat sink 3 is provided with a heat dissipation channel 31, and the heat dissipation channel 31 is all composed of LED Enclosed by the lamp substrate 2 , the heat dissipation channel 31 is provided with an air inlet 32 and an air outlet 33 , and the distribution density of LED lamps gradually decreases along the air inlet 32 to the air outlet 33 of the heat dissipation channel 31 . In the state of use, the air inlet 32 is located at the lower side of the heat dissipation passage 31 , and the air outlet 33 is located at the upper side of the heat dissi...

Embodiment 3

[0054] Such as Figure 10 As shown, it is roughly the same as Embodiment 2, the difference is that a second heat conduction layer 35 is added at the place where the LED lamp substrate 2 is close to the heat dissipation channel 31, which is beneficial to mold processing. During the installation process, only the LED lamp needs to be It only needs to adhere the substrate 1 on the second heat conducting layer 35 . The material of the second heat conduction layer 35 is aluminum alloy, and the thickness of the second heat conduction layer 35 is 0.8 mm.

[0055] This embodiment is not limited to bulb-shaped LED lamps, and can also be applied to LED lamps used for street lamps. For the sake of brevity, this embodiment will not be described in detail one by one, but its principle is the same as this embodiment .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com