A kind of control method of vibration system

A control method and vibration system technology, applied in the field of construction machinery, can solve the problems of increasing user operating costs, increasing energy consumption, and high noise levels, and achieving the effects of improving efficiency, reducing rotational speed, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

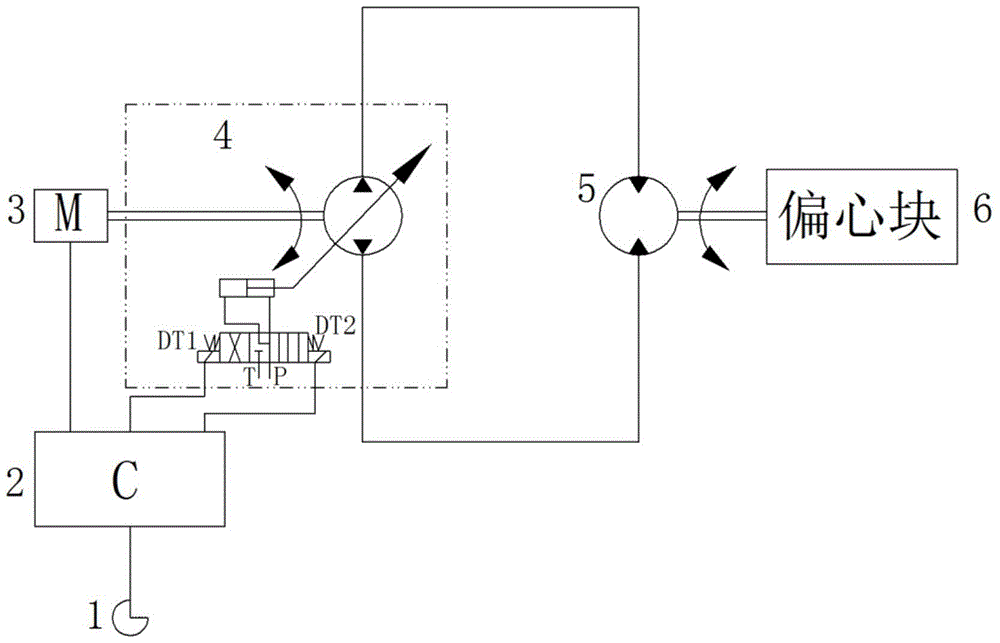

[0018] The present invention will be further described below in conjunction with accompanying drawing.

[0019] A vibration system includes an electronically controlled engine 3 , a hydraulic two-way plunger pump 4 , a hydraulic two-way plunger motor 5 , a controller 2 , and a vibration handle (knob) 1 .

[0020] The hydraulic two-way plunger pump 4 is connected in parallel with the hydraulic two-way plunger motor 5 to form a closed hydraulic circuit. The electric control engine 3 directly drives the hydraulic two-way plunger pump 4, and the hydraulic two-way plunger pump 4 supplies high-pressure oil to the hydraulic circuit to drive the hydraulic two-way The plunger motor 5 rotates, the vibration handle (knob) 1 is electrically connected with the controller 2, and transmits the operation mode information to the controller 2; DT2 is electrically connected. The controller 2 controls the rotation speed of the electronically controlled engine 3 and the power gain and loss of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com