Preparation method of carbon nano-tube grafted glass fiber fabric reinforcement

A carbon nanotube and glass fiber technology, used in fiber processing, textiles and papermaking, etc., can solve the problem of carbon nanotubes being difficult to uniformly disperse, and achieve the effects of improved tensile strength, good molding processability, and improved modulus.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

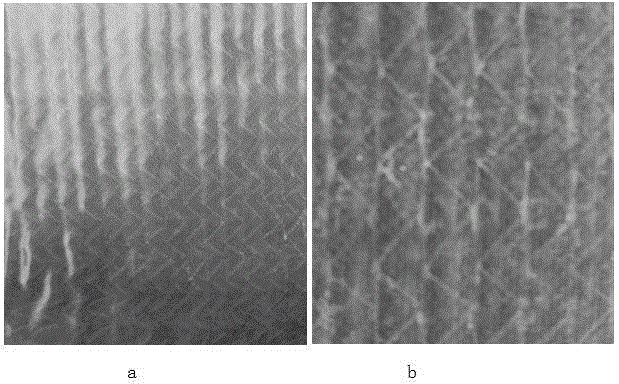

Image

Examples

Embodiment 1

[0025] (1) The area density is 400g / m 2 Glass fiber grid fabric (take 10 cm×10cm as an example), put it in an oven and bake it at 80±10°C for 2 hours;

[0026] (2) Under stirring conditions, slowly add 0.5g of epoxy silane grafting agent into 75% ethanol aqueous solution (100ml), adjust the pH=6±0.5 with 0.1% acetic acid, stir for 20min, and obtain the grafting agent solution;

[0027] (3) Slowly disperse 60 mg of hydroxyl carbon nanotubes in the above-mentioned grafting agent solution under ultrasonic vibration to obtain a grafting agent solution containing carbon nanotubes;

[0028] (4) Immerse the dried glass fiber fabric in the above carbon nanotube-containing grafting agent solution, put it in an oven at 100°C for 2 hours after immersion, and obtain a glass fiber composite reinforcement with surface grafted carbon nanotubes. The content of carbon nanotubes in the body is: 60mg / 100cm 2 glass fiber.

[0029] Compared with the glass fiber / epoxy composite material, the com...

Embodiment 2

[0031] (1) The area density is 1200g / m 2 Glass fiber grid fabric (take 10 cm×10cm as an example), put it in an oven and dry it at 80±10°C for 2 hours;

[0032] (2) Stir 3.0g of vinylsilane grafting agent, slowly add 75% ethanol aqueous solution (100ml), adjust pH=6±0.5 with 0.1% acetic acid, stir for 20min, and obtain grafting agent solution;

[0033] (3) Slowly disperse 100 mg of mercapto carbon nanotubes in the grafting agent solution under ultrasonic vibration to obtain a grafting agent solution containing carbon nanotubes.

[0034] (4) Put the above-mentioned grafting agent solution containing carbon nanotubes into a high-pressure watering can, then evenly spray it on the surface of the activated glass fiber, and dry it at 110°C for 2 hours to obtain a composite reinforcement of carbon nanotube-grafted glass fiber Medium carbon nanotube content: 100mg / 100cm 2 glass fiber. Immerse the above-mentioned dried glass fiber fabric in the above-mentioned grafting agent solution...

Embodiment 3

[0037] (1) The surface density is 100g / m 2 Glass fiber plain weave fabric (take 10 cm×10cm as an example), put it in an oven and dry it at 80±10°C for 2 hours;

[0038] (2) Stir 4.5g of diphenylmethane diisocyanate grafting agent, slowly add 10ml of benzene in acetone solution (100ml), stir well to obtain grafting agent solution;

[0039] (3) Slowly disperse 1900 mg of hydroxylated carbon nanotubes in the grafting agent solution under ultrasonic vibration to obtain a grafting agent solution containing carbon nanotubes.

[0040] (4) Immerse the above-mentioned dried glass fiber fabric in the above-mentioned grafting agent solution containing carbon nanotubes. After dipping for 8 seconds, put it in an oven at 80°C for 2 hours to obtain a glass fiber composite reinforcement with surface-grafted carbon nanotubes. The content of carbon nanotubes in the body is: 2100mg / 100cm 2 glass fiber.

[0041] The composite material prepared by grafting the above-mentioned carbon nanotubes w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com