Method for Melting Nickel-Based Alloy in Non-vacuum Induction Furnace

A non-vacuum induction furnace, nickel-based alloy technology, applied in the field of metallurgy, can solve the problems of complex structure, difficult operation, high price, etc., and achieve the effect of improving comprehensive mechanical properties, strong deoxidation and degassing ability, and reducing scrap rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

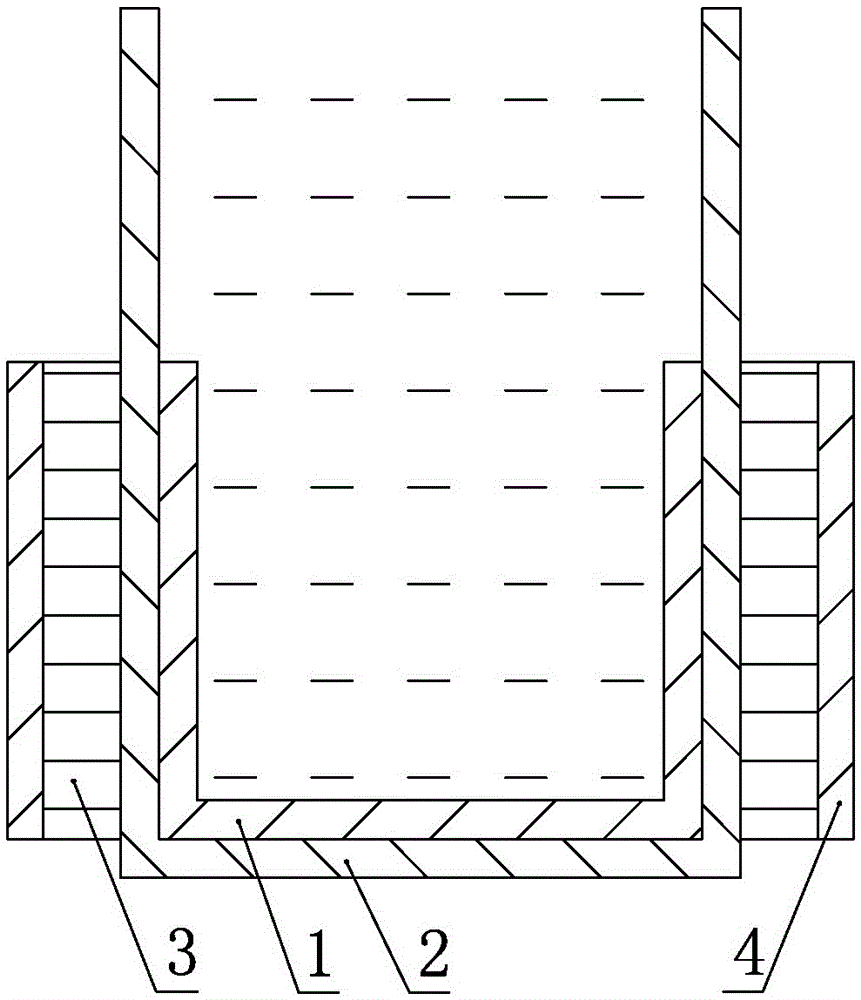

[0014] In this embodiment, the material of smelting 95kg is taken as an example for illustration, such as figure 1 As shown, a crucible 1 is set in the furnace 2 of the intermediate frequency induction furnace, the height ratio of the crucible 1 to the height of the furnace 2 is 0.4:1, the induction coil 3 is wound on the outer wall of the furnace 2 and the height of the induction coil 3 is not higher than The height of the crucible 1, the load quality factor of the induction coil 3 is 20, the number of turns of the induction coil 3 is 18 turns, the distance between each turn is 2.9mm, the ratio of the height of the induction coil 3 to the diameter of the induction coil 3 is 1:0.65 , the induction coil 3 is also covered with a crucible cover 4; then 95kg of material to be smelted is put into the crucible 1 for melting, and the liquid level height of the melted molten metal will be higher than the height of the induction coil 3. This implementation In the example, the liquid le...

Embodiment 2

[0016] In this embodiment, smelting 100kg of material is taken as an example for illustration, such as figure 1 As shown, a crucible 1 is set in the furnace 2 of the intermediate frequency induction furnace, the height ratio of the crucible 1 to the height of the furnace 2 is 0.51:1, the induction coil 3 is wound on the outer wall of the furnace 2 and the height of the induction coil 3 is not higher than The height of the crucible 1, the load quality factor of the induction coil 3 is 20, the number of turns of the induction coil 3 is 18 turns, the spacing between each turn is 3mm, the height of the induction coil 3 and the diameter ratio of the induction coil 3 are 1:0.712, The induction coil 3 is also provided with a crucible cover 4; then 100kg of material to be smelted is put into the crucible 1 for melting, and the liquid level height of the melted molten metal is higher than the height of the induction coil 3. In this embodiment, In the process, the liquid level of the me...

Embodiment 3

[0018] In this embodiment, the material of smelting 105kg is taken as an example for illustration, such as figure 1 As shown, a crucible 1 is set in the furnace 2 of the intermediate frequency induction furnace, the height ratio of the crucible 1 to the height of the furnace 2 is 0.6:1, the induction coil 3 is wound on the outer wall of the furnace 2 and the height of the induction coil 3 is not higher than The height of the crucible 1, the load quality factor of the induction coil 3 is 20, the number of turns of the induction coil 3 is 18 turns, the distance between each turn is 3.1mm, and the ratio of the height of the induction coil 3 to the diameter of the induction coil 3 is 1:0.75 , the induction coil 3 is also covered with a crucible cover 4; then 105kg of material to be smelted is put into the crucible 1 for melting, and the liquid level height of the melted molten metal will be higher than the height of the induction coil 3. This implementation In the example, the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com