Hydrophilic aluminum foil with organic-inorganic hybrid coating, and preparation method and application thereof

A hydrophilic aluminum foil and coating technology, which is applied in the field of aluminum foil, can solve the problems of no investigation on the flatness of the film, poor adhesion of the hydrophilic coating, and high curing temperature, and achieve the effects of low cost, good adhesion, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

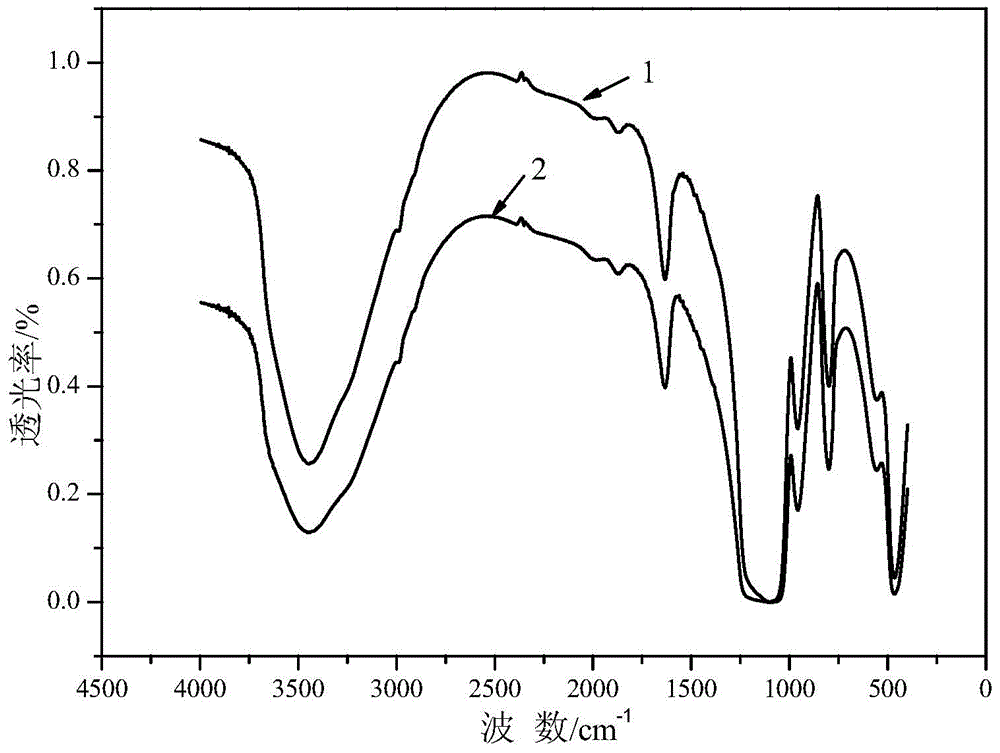

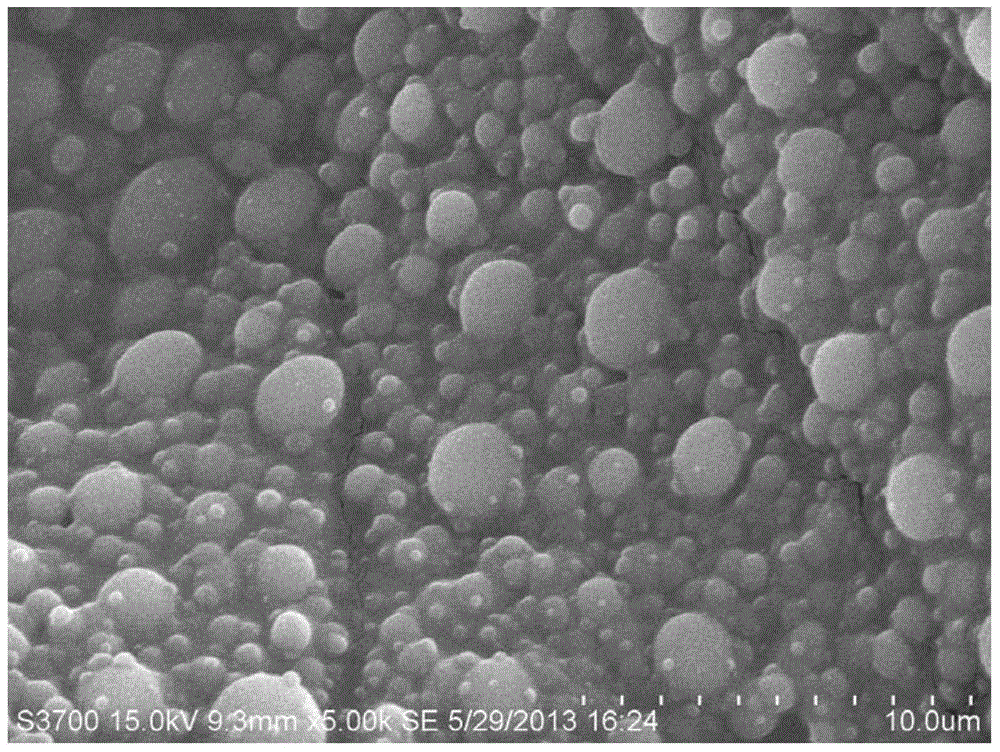

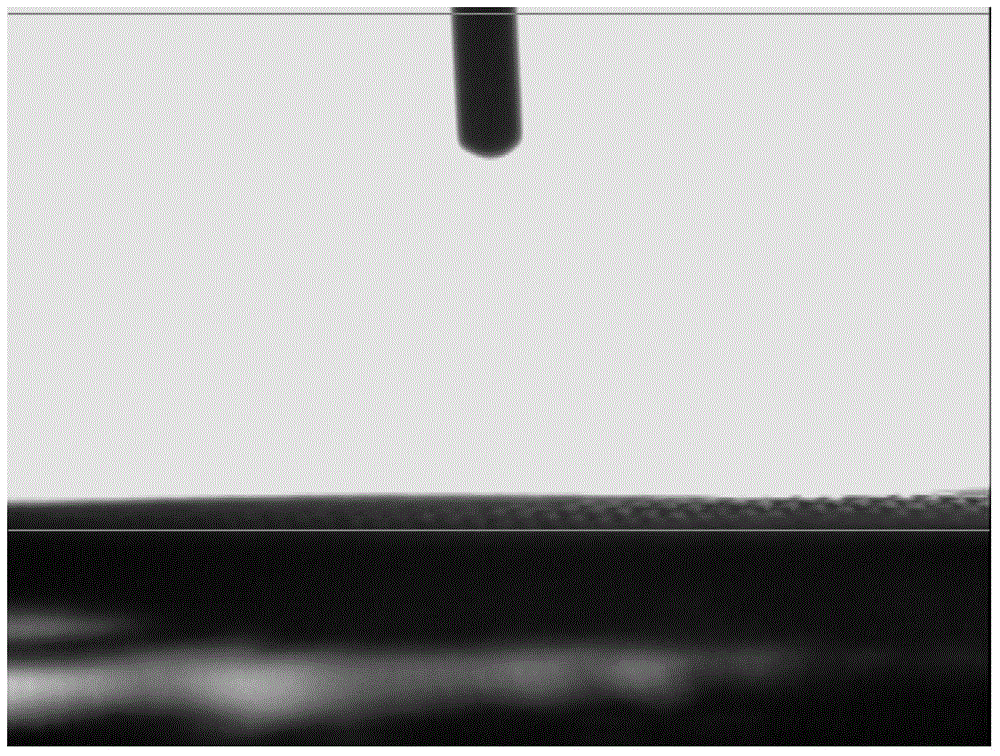

[0031] (1) Add 50g of tetraethoxysilane, 100g of absolute ethanol and 20g of deionized water into a four-neck flask, heat in a constant temperature water bath at 35°C and keep stirring. After stirring evenly, weigh 0.5g of 25% Add ammonia water to 30g of deionized water, drop it into a four-necked flask at a rate of 1ml / min with a constant flow pump, keep warm for 4 hours, and discharge to prepare a nano-silica sol with a particle size of about 10nm, with a mass content of nanoparticles of 20%. The structure of the synthesized nanoparticles was tested by a Fourier transform infrared tester, and the figure 1 The infrared spectrum is visible at 3400cm ‐1 There is a strong absorption peak at , which is the absorption peak of hydroxyl-OH, at 930cm ‐1 The stretching vibration peak of silanol Si-OH is at 1000-1100cm ‐1 The strong and broad absorption peak is the stretching vibration absorption peak of Si-O, and there is also the stretching vibration absorption peak of Si-O-Si (tet...

Embodiment 2

[0039] (1) Add 50g of tetraethoxysilane, 100g of absolute ethanol and 20g of deionized water into a four-neck flask, heat in a constant temperature water bath at 80°C and keep stirring. After stirring evenly, weigh 0.5g of 25% Add hydrochloric acid to 30 g of deionized water, drop it into a four-neck flask with a constant flow pump at a rate of 1 ml / min, keep warm for 4 hours, and discharge to prepare a nano-silica sol with a particle size of 500 nm, and the mass content of the nanoparticles is 35%. The structure of the synthesized nanoparticles was tested with a Fourier transform infrared tester, and figure 1 resemblance.

[0040] (2) hydroxyl acrylic resin is mixed with 20% aqueous solution to obtain hydrophilic film-forming agent;

[0041] (3) Mix the nano-sol in step (1) with the hydrophilic film-forming agent obtained in step (2) according to the solute mass ratio of 1:5, add 5g of glutaraldehyde, dilute with water and prepare a solution with a mass concentration of 10%....

Embodiment 3

[0047] (1) Add 50g of tetramethoxysilane, 100g of absolute ethanol and 20g of deionized water into a four-necked flask, heat it in a constant temperature water bath at 35°C and keep stirring. After stirring evenly, weigh 0.5g of 25% Sodium bicarbonate, add 30g deionized water, drip in the four-necked flask with the speed of 1.5ml / min with constant flow pump, after keeping warm for 5h, discharge the material to prepare the nano-silica sol with particle diameter 200nm, the mass content of nano-particles is 35% . The structure of the synthesized nanoparticles was tested with a Fourier transform infrared tester, and figure 1 resemblance;

[0048] (2) Polyethylene glycol is formulated into a 1% aqueous solution to obtain a hydrophilic film-forming agent;

[0049] (3) the nano sol in the step (1) is mixed with the hydrophilic film-forming agent obtained in the step (2) in a solute mass ratio of 1:1, add 1g of diisocyanate, and dilute with water to form a solution with a mass conce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com