Nylon material and preparation method thereof

A nylon and raw material technology, applied in the field of nylon materials and their preparation, can solve the problems of complex operation and unsatisfactory effects of modified nylon materials, and achieve the effects of superior product performance, good application performance, and enhanced modification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

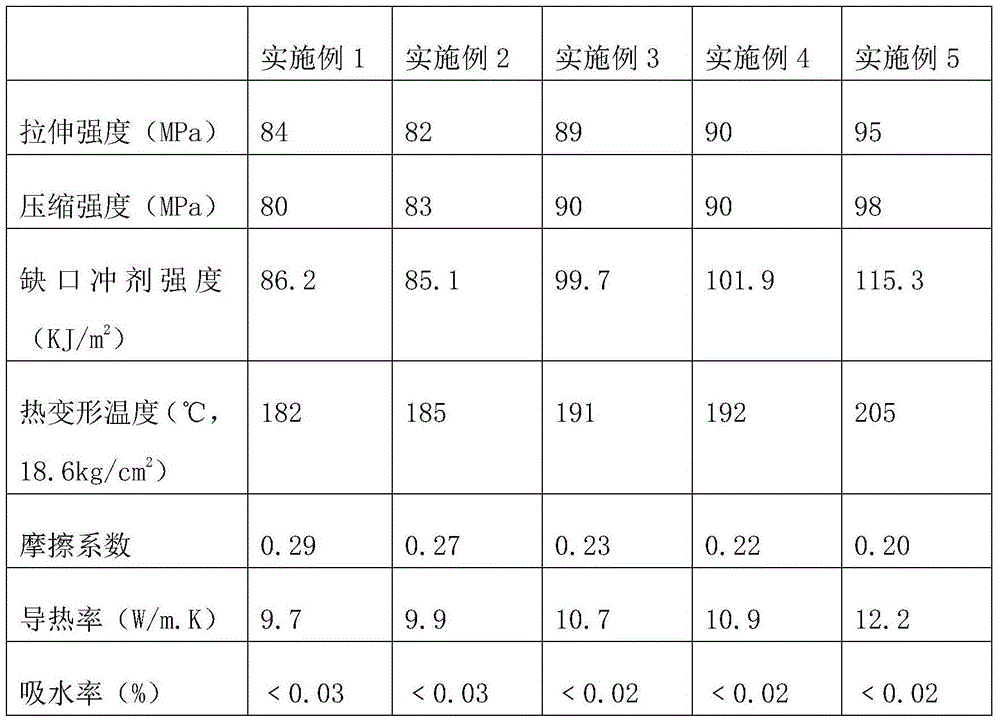

Examples

Embodiment 1

[0025] The nano-modified nylon material described in this embodiment is prepared from the following raw materials:

[0026] 100kg of nylon matrix, 2kg of nano-silicon carbide, 4kg of nano-silicon dioxide, 1kg of aminopropyltriethoxysilane, 5kg of phenolic resin, 10kg of glass fiber, and 1L of volatile solvent that is liquid at room temperature.

[0027] The method for preparing nano-modified nylon material described in this embodiment comprises the steps:

[0028] (1) Take the nano-silicon carbide, nano-silicon nitride, and nano-silicon dioxide according to the selected weight and mix them evenly, add them to the volatile solvent of the selected volume, and mix them for subsequent use;

[0029] (2) Take the nylon matrix, aminopropyltriethoxysilane, phenolic resin and glass fiber according to the selected parts by weight and mix them evenly, and heat them to 40°C for 1-2h; Carry out a gradient temperature rise program, specifically, increase the temperature by 15°C in 2-3 minu...

Embodiment 2

[0032] The nano-modified nylon material described in this embodiment is prepared from the following raw materials:

[0033] 100kg of nylon matrix, 6kg of nano-silicon carbide, 10kg of nano-silicon dioxide, 0.3kg of aminopropyltriethoxysilane, 15kg of phenolic resin, 3kg of glass fiber, and 10L of volatile solvent that is liquid at room temperature.

[0034] The method for preparing nano-modified nylon material described in this embodiment comprises the steps:

[0035] (1) Take the nano-silicon carbide and nano-silicon dioxide according to the selected weight and mix them evenly, add them to the volatile solvent of the selected volume, and mix them for subsequent use;

[0036] (2) Take the nylon matrix, aminopropyl triethoxysilane, phenolic resin and glass fiber according to the selected parts by weight and mix them evenly, and heat to 40°C for 2 hours; then use the temperature difference of 20°C as a gradient Carry out a gradient temperature rise program, specifically, increa...

Embodiment 3

[0039] The nano-modified nylon material described in this embodiment is prepared from the following raw materials:

[0040] 100kg of nylon matrix, 3kg of nano-silicon carbide, 6kg of nano-silicon dioxide, 0.8kg of aminopropyltriethoxysilane, 7kg of phenolic resin, 8kg of glass fiber, and 3L of volatile solvent that is liquid at room temperature.

[0041] The method for preparing nano-modified nylon material described in this embodiment comprises the steps:

[0042] (1) Take the nano-silicon carbide and nano-silicon dioxide according to the selected weight and mix them evenly, add them to the volatile solvent of the selected volume, and mix them for subsequent use;

[0043] (2) Take the nylon matrix, aminopropyltriethoxysilane, phenolic resin and glass fiber according to the selected parts by weight and mix them evenly, and heat them to 50°C for 1 hour; then use a temperature difference of 15°C as a gradient Carry out a gradient temperature rise program, specifically, increase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com