Hyperbranched polyester resin pigment dispersant as well as preparation method thereof, color paste and application of color paste

A technology of hyperbranched polyester and resin pigments, applied in pigment paste, chemical instruments and methods, transportation and packaging, etc., can solve the problem of reducing the hydroxyl functional group of hyperbranched polyester, which is not conducive to crosslinking reaction, acid resistance, alkali resistance, Problems such as resistance to adverse effects of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

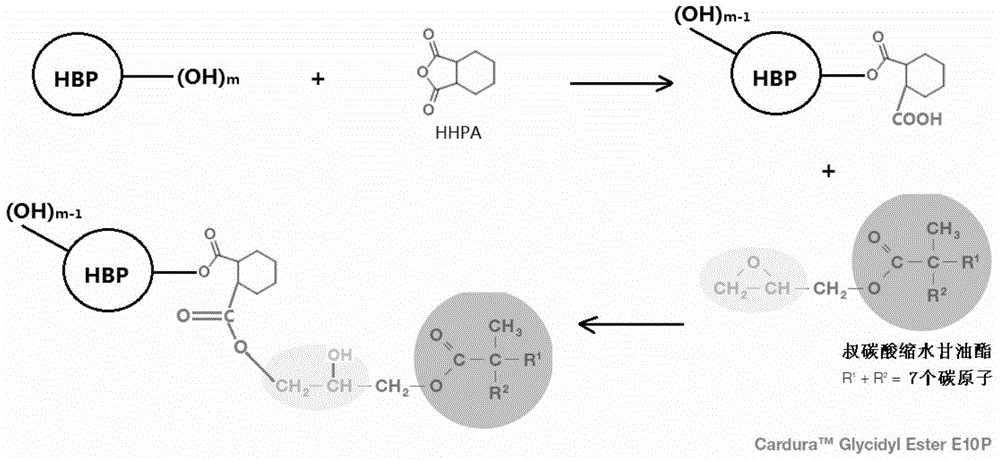

Method used

Image

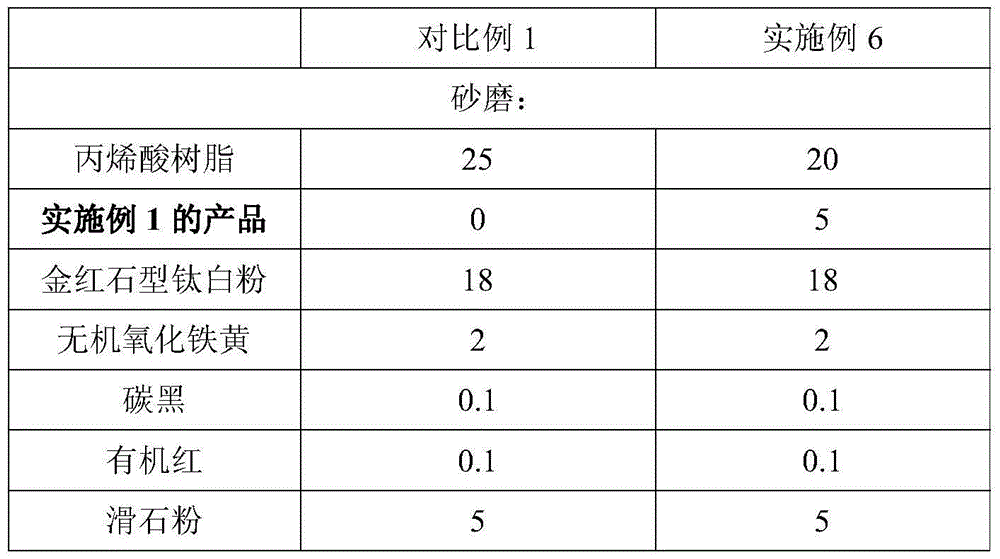

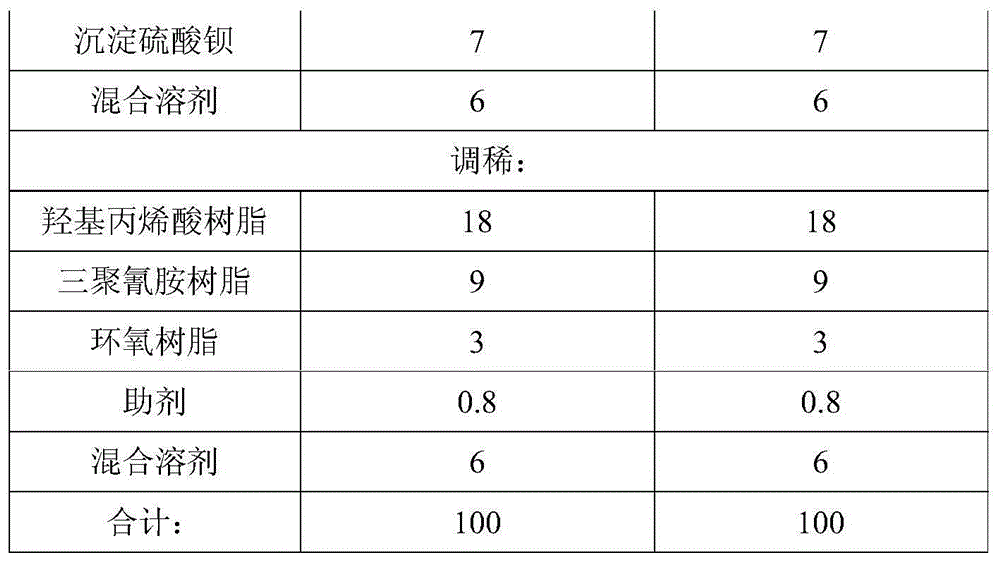

Examples

Embodiment 1

[0048] (1) Add Boltorn H4001 solution containing 1 mole of hydroxyl groups and 0.5 mole of methylhexahydrophthalic anhydride to a four-necked flask with a stirrer, thermometer and condenser, start stirring and heat up to 130°C , at 130°C - heat preservation reaction;

[0049] (2) Detect the acid value of the solution after reacting for 1 hour, and then detect the acid value of the solution every 30 minutes until the acid value of the solution is stable. Then add 0.5 mole of glycidyl tert-butyl benzoate, and keep it warm at 140°C for reaction. After 4 hours, check the acid value of the solution every hour until the acid value of the solution reaches a stable range of 2-10mgKOH / g, which is the end of the reaction. Add diluting solvent butyl acetate, adjust the solid content to 70%, and obtain a light yellow transparent liquid, which is the product hyperbranched polyester resin pigment dispersant, with a solid primary hydroxyl content of 4.3%, a number average molecular weight of...

Embodiment 2

[0051] (1) Add Boltorn H4001 solution containing 1 mole of hydroxyl groups and 0.3 mole of phthalic anhydride to a four-necked flask with a stirrer, thermometer and condenser, start stirring and raise the temperature to 110°C, at 110°C insulation reaction;

[0052] (2) Check the acid value after 1 hour of reaction, and then check the acid value every 30 minutes until the acid value is stable. Then add 0.3 mole of glycidyl 2-ethylhexanoate, keep the temperature at 150°C for reaction, check the acid value every 1 hour after 4 hours, until the acid value reaches a stable range of 2-10mgKOH / g, which is the end of the reaction, add Dilute solvent butyl acetate, adjust solid content 70%, the product that obtains is a kind of light yellow transparent liquid and is product hyperbranched polyester pigment dispersant, and its solid primary hydroxyl content is 5.4%, number average molecular weight is 5730, weight average The molecular weight is 10550.

Embodiment 3

[0054] (1) Add Boltorn H4001 solution containing 1 mole of hydroxyl groups and 0.1 mole of trimellitic anhydride to a four-necked flask with a stirrer, a thermometer and a condenser, start stirring and heat up to 110°C, and keep warm at 110°C for reaction;

[0055] (2) Check the acid value after 1 hour of reaction, and then check the acid value every 30 minutes until the acid value is stable. Then add 0.2 moles of glycidyl tertiary carbonic acid ester, keep it warm at 140°C, and check the acid value every hour after 4 hours until the acid value reaches a stable range of 2 to 10 mgKOH / g, which is the end of the reaction, and add the diluting solvent butyl acetate Ester, adjust the solid content to 70%, and the product obtained is a light yellow transparent liquid, which is a hyperbranched polyester pigment dispersant, and the solid primary hydroxyl content is 7.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com