A kind of treatment method of pickling wastewater in iron and steel industry

A technology for pickling wastewater and treatment methods, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., and can solve the problems of waste of metal resources, difficulty in recycling, and non-recyclability. , to achieve the effect of reducing investment and operating costs, high metal particle separation efficiency, saving space and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

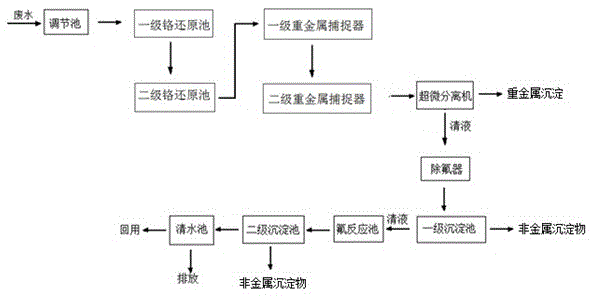

Image

Examples

Embodiment 1

[0026] Embodiment 1 adopts the method of the present invention to process the pickling wastewater discharged from the cold rolling section of a certain steel plant

[0027] 1. The pickling wastewater discharged from the cold rolling section of a steel factory was introduced into the regulating tank, and the total iron in the wastewater was measured to be 3000mg / L, the concentration of chromium ions was 800mg / L, the concentration of nickel ions was 200mg / L, and the concentration of fluoride ions was 2000mg / L. pH between 1-2;

[0028] 2. The wastewater is introduced into the chromium reduction pool from the adjustment pool. The chromium reduction pool is divided into a primary chromium reduction pool and a secondary chromium reduction pool. The wastewater flows through the primary chromium reduction pool and the secondary chromium reduction pool in turn. Each level of chromium reduction A sufficient amount of reducing agent sodium metabisulfite is added to the pool for 30 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com