Thick oil sewage treatment coagulating agent, and preparation method and application thereof

A technology of heavy oil sewage and coagulant, applied in flocculation/sedimentation water/sewage treatment, separation method, grease/oily substance/float removal device, etc., can solve the problems of poor effect, weak effect, substandard water quality, etc. , to achieve the effect of simple preparation process, strong impact resistance and fast settling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

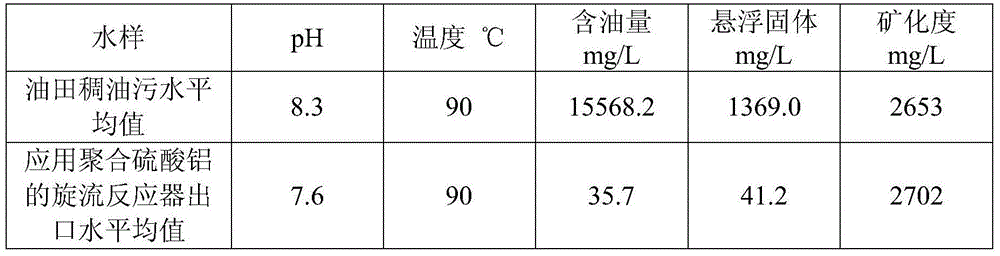

[0021] First add 20wt% of polyaluminum chloride and 10wt% of polysilicon zinc sulfate into water, and then add 1.0wt% of polydimethyldiallylammonium chloride and 5.0wt% of 3.0G polyamide-amine after dissolution is complete , stir evenly, adjust the pH value to 3.0, and obtain a coagulant for heavy oil sewage treatment. This formula is suitable for the purification treatment of heavy oil high temperature sewage and has excellent effect. The heavy oil sewage treatment coagulant and polyaluminum sulfate were respectively added to the inlet of the cyclone reactor in the treatment process of a heavy oil sewage station in an oil field. The application effect of coagulant and polyaluminum sulfate for oily high-temperature sewage treatment is shown in Table 1 (Note: The dosage of the agent is calculated according to the effective content).

[0022] Table 1 Application effect of coagulant in heavy oil high temperature sewage treatment

[0023]

[0024]

[0025] As can be seen f...

Embodiment 2

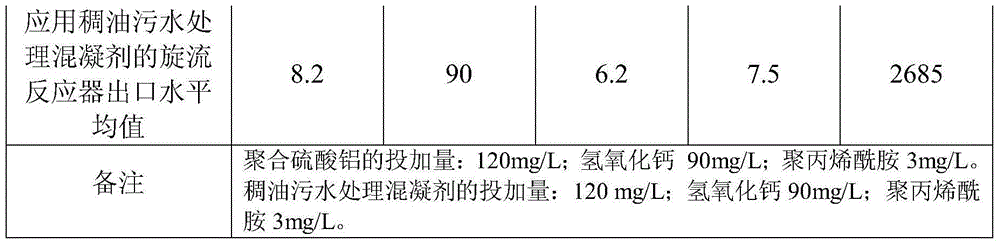

[0027] First add 25wt% of polyaluminum chloride and 5wt% of polysilicon zinc sulfate into water, and then add 0.5wt% of polydimethyldiallyl ammonium chloride and 10.0wt% of 3.0G polyamide-amine after dissolution is complete , stir evenly, adjust the pH value to 5.0, and obtain a coagulant for heavy oil sewage treatment. This formula is suitable for the purification treatment of heavy oil high-temperature sewage, and the effect is stable. The heavy oil sewage treatment coagulant and polyaluminum sulfate were respectively added to the inlet of the cyclone reactor in the treatment process of a heavy oil sewage station in an oil field. Significantly decreased, the application effect of coagulant and polyaluminum sulfate for heavy oil high temperature sewage treatment is shown in Table 2 (Note: The dosage of the agent is calculated according to the effective content).

[0028] Table 2 Application effect of coagulant in heavy oil high temperature sewage treatment

[0029]

[00...

Embodiment 3

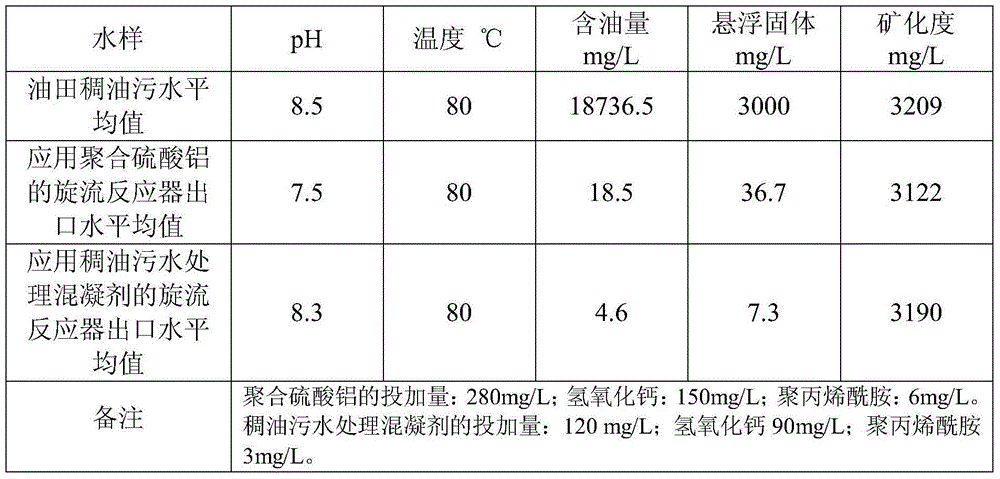

[0032]First add 15wt% of polyaluminum chloride and 8wt% of polysilicon zinc sulfate into water, and then add 0.7wt% of polydimethyldiallyl ammonium chloride and 8wt% of 3.0G polyamide-amine after dissolving completely, Stir evenly, adjust the pH value to 4.0, and obtain the coagulant for heavy oil sewage treatment. This formula is suitable for the purification treatment of heavy oil high-temperature sewage, and the effect is stable. The heavy oil sewage treatment coagulant and polyaluminum sulfate were respectively added to the inlet of the cyclone reactor in the treatment process of a heavy oil sewage station in an oil field. Significantly decreased, the application effect of coagulant for heavy oil high-temperature sewage treatment is shown in Table 3 (Note: The dosage of the agent is calculated according to the effective content).

[0033] Table 3 Application effect of coagulant in heavy oil high temperature sewage treatment

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com