High-salinity and high organic matter wastewater treatment process

A technology for wastewater treatment and organic matter, which is applied in the direction of heating water/sewage treatment, etc., can solve the problems of difficult popularization and application of technology, high operating costs and investment costs, and achieve the effects of simple equipment maintenance, small footprint, and low treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

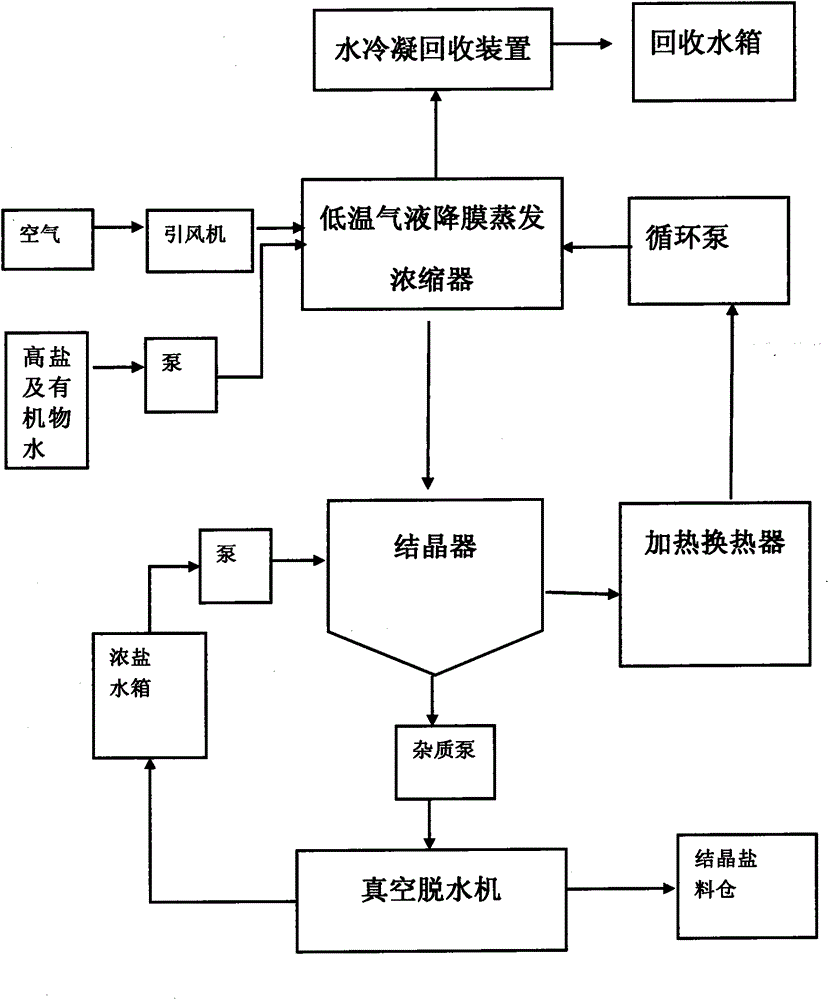

[0011] Below in conjunction with accompanying drawing and embodiment the present invention is further described, a kind of high-salt high-organic waste water treatment process, concrete process steps are as follows:

[0012] 1. The air is introduced into the low-temperature falling film evaporation concentrator through the fan along the air duct. The working temperature of the falling film evaporation concentrator is 50-70°C. The high-salt and high-organic waste water is introduced into the low-temperature gas-liquid falling film evaporation concentrator through pumps and pipelines , High-salt and high-organic waste water exchanges gas-liquid with air in the gas-liquid falling film evaporator, high-salt and high-organic waste water is converted from liquid phase to gas phase and enters the air to concentrate brine;

[0013] 2. After the brine is concentrated, it flows into the crystallizer through the pipeline. The crystallizer adopts the crystal seed method crystallization tec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com