An automatic folder-gluer and a water-based glue sealing process based on the folder-gluer

A water-based glue and folder-gluer technology, which is applied in container manufacturing machinery, box-making operations, and devices for coating liquids on surfaces, etc. Problems such as temperature resistance and environmental protection standards are impossible to meet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited to the following embodiments.

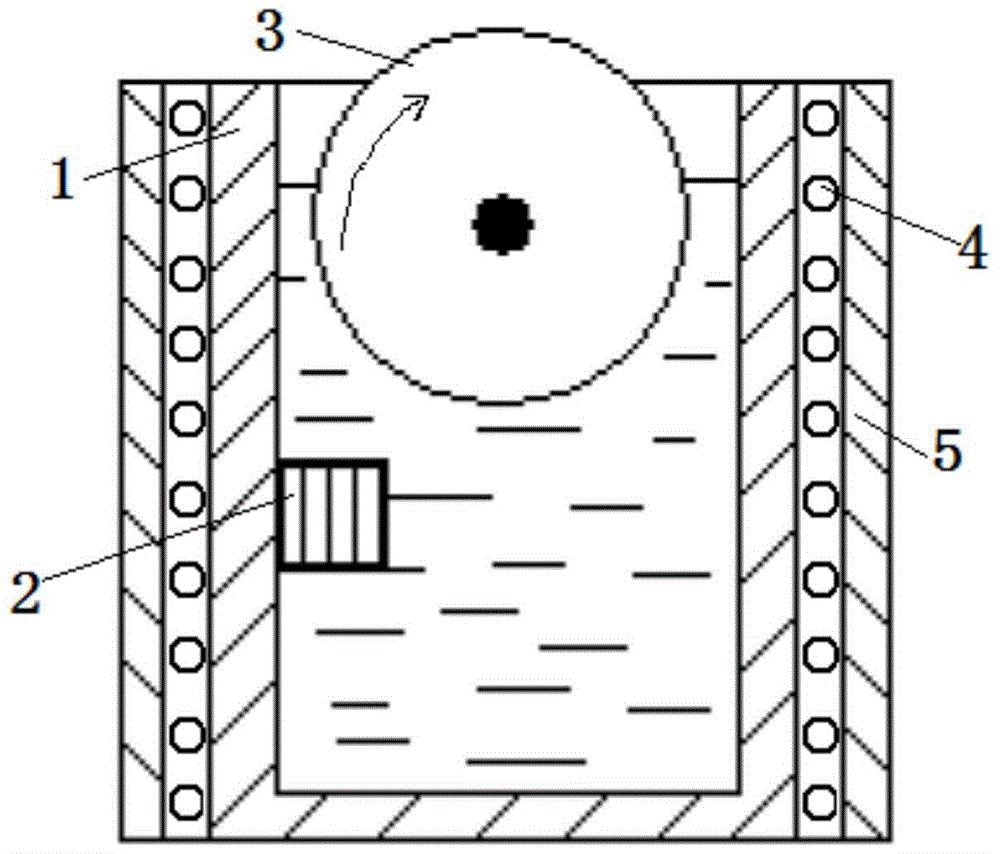

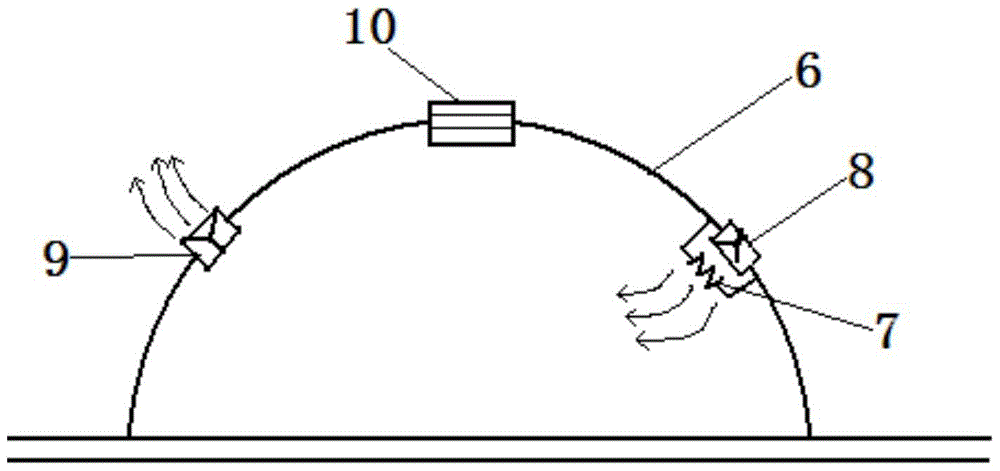

[0037] The automatic folder gluer for water-based glue sealing process provided by the present invention at least includes equipment base, metal glue tank 1, paper feeder, conveying platform, pre-folding device and pressing device, and the above-mentioned parts are the same as the existing automatic gluer. The boxes are basically the same. The structure of metal glue tank 1 in the present embodiment is as figure 1 As shown, a temperature sensor 2 is arranged in the metal glue tank 1, and a display is arranged outside the tank correspondingly to display the temperature of the water-based glue in the metal glue tank; a layer of thermal insulation material 5 is arranged on the outer wall of the metal glue tank 1 A heating element 4 is also arranged be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com