Double-end-face double-piston spindle for machine tool

A double-end, double-piston technology, applied in the direction of metal processing machinery parts, large fixed members, metal processing equipment, etc., can solve the problems of lowering the use of standards, restricting the development of CNC machine tools, and unable to guarantee concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

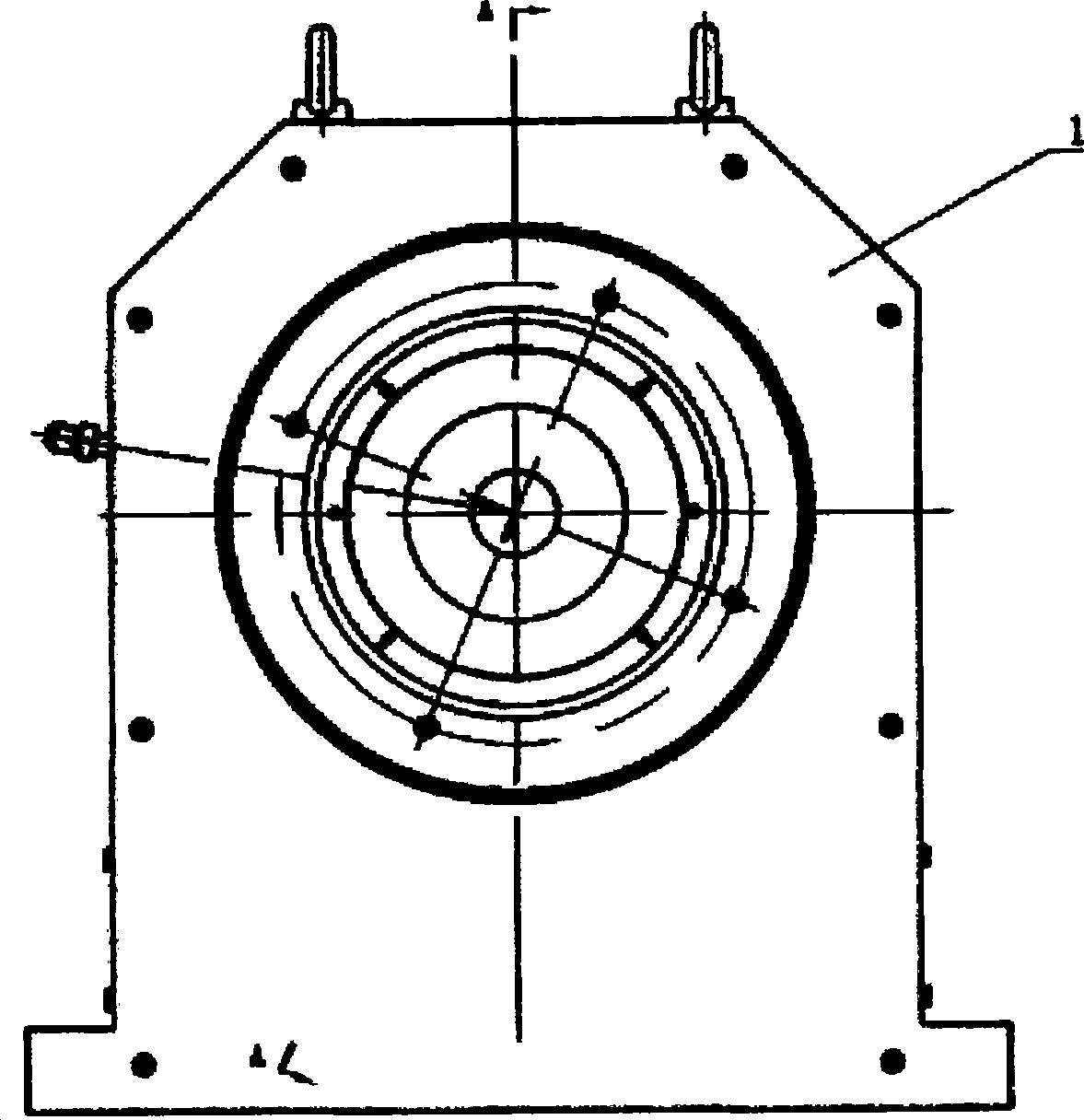

[0012] The present invention will be further described below in conjunction with accompanying drawing.

[0013] as attached Figure 1-2 As shown, a double-end double-piston spindle for a machine tool of the present invention is composed of a spindle main body 1, a bearing, a gland 2, a spindle 3, a belt 4, an oil cylinder 5 and a fixture 6, and the spindle 3 is rotatably connected to the In the main shaft body 1, the belt 4 is connected to the main shaft to drive the main shaft 3 and the clamped workpiece 7 to rotate. The outside of the bearing is fixed by the gland 2. At the end, the jig 6 is driven by the oil cylinder 5, wherein the gland 2, the bearing, the oil cylinder 5 and the jig 6 are all arranged in pairs and arranged substantially symmetrically along the longitudinal centerline of the main shaft body 1. The clamp 6 may be a chuck or collet.

[0014] The invention relates to a double-end surface double-piston main shaft for a machine tool, which can complete the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com